A biodegradable polymer porous urethral repair scaffold and its preparation method

A polymer and polymer material technology, applied in the field of medical repair and tissue engineering, can solve the problems of limited material sources, no clinical application data, and the impracticality of repairing long-term tubular defects of the urethra, and achieve simple and efficient preparation process Convenience and the effect of avoiding the residue of organic solvents and porogens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

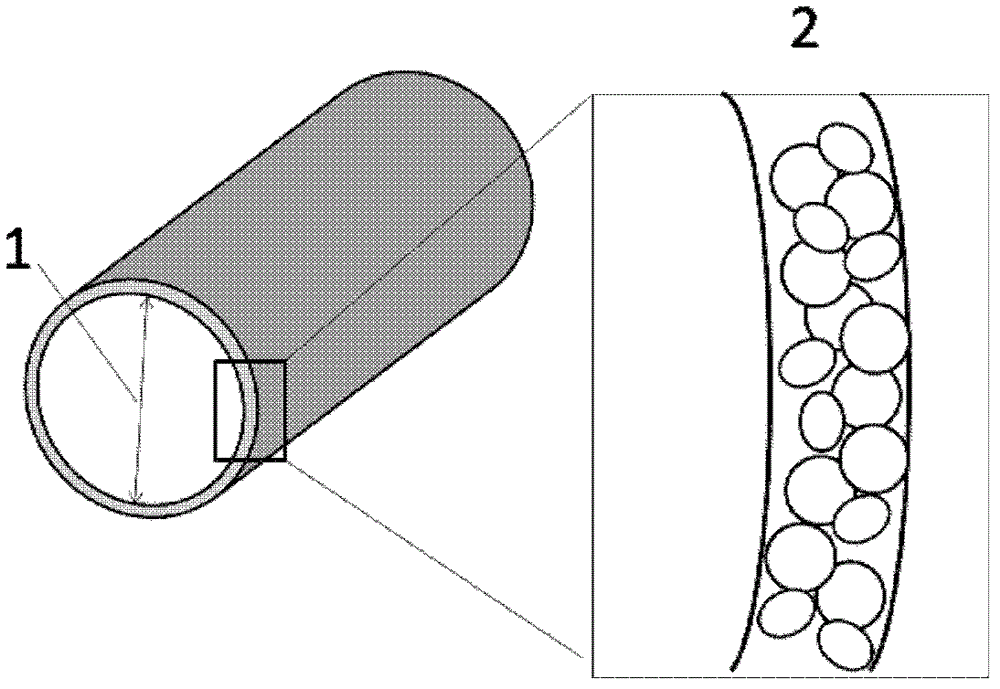

[0029] Polycaprolactone urethral repair scaffolds with inner diameters of 2.5mm, 3.5mm and 4.5mm were prepared.

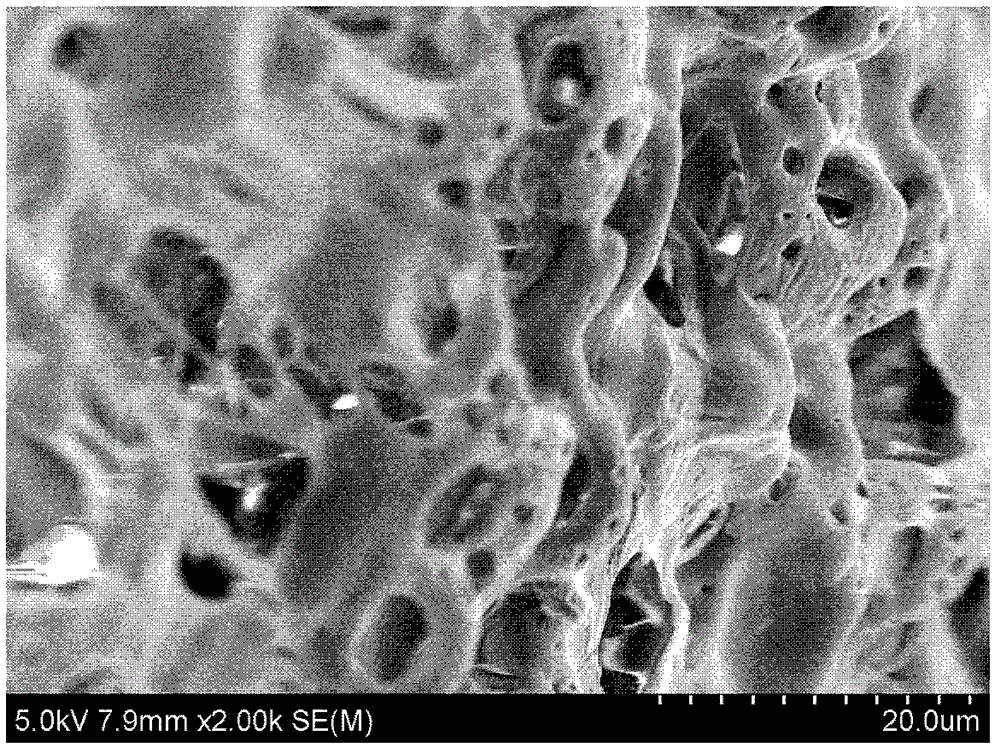

[0030] Weigh 4g of PCL and dissolve in 20ml of dichloromethane, heat and condense to reflux for 1 hour to dissolve and form an oil phase. Weigh 15g of ammonium bicarbonate and dissolve in 100ml of water, and dissolve at room temperature until completely dissolved to form an aqueous phase. The water phase and the oil phase are mixed at a volume ratio of 1:3 and homogenized at a speed of 2500 rpm to form a viscous emulsion. Quickly insert glass rods with diameters of 2.5mm, 3.5mm, and 4.5mm into the emulsion, and immediately take them out after stirring and dry them at room temperature for 12 hours, then freeze-dry the samples to remove organic solvents, and obtain porous polymer Urethral repair stent.

[0031] The obtained polymer porous urethral repair scaffold has good toughness, and moderate stretching, curling or folding in half will not cause fracture, but th...

Embodiment 2

[0036] PLA-CL (7:3) urethral repair scaffolds with inner diameters of 2.5mm, 3.5mm, and 4.5mm were prepared.

[0037] Weigh 4g of PLA-CL (7:3) and dissolve in 20ml of dichloromethane / chloroform (dichloromethane occupies 80% of the volume), heat and reflux for 1 hour to dissolve and form an oil phase. Weigh 15g of ammonium bicarbonate and dissolve in 100ml of water, and dissolve at room temperature until completely dissolved to form an aqueous phase. The water phase and the oil phase are mixed at a volume ratio of 1:2 and homogenized at a speed of 2500 rpm to form a viscous emulsion. Quickly insert glass rods with diameters of 2.5mm, 3.5mm, and 4.5mm into the emulsion, and immediately take them out after stirring and dry them at room temperature for 12 hours, then freeze-dry the samples to remove organic solvents, and obtain porous polymer Urethral repair stent.

[0038] The obtained polymeric porous urethral repair scaffold has good toughness, moderate stretching, curling or...

Embodiment 3

[0043] PLA-CL (8:2) urethral repair scaffolds with inner diameters of 2.5mm, 3.5mm and 4.5mm were prepared.

[0044]Weigh 4g of PLA-CL (8:2) and dissolve in 20ml of dichloromethane / ethyl acetate (dichloromethane occupies 70% of the volume), heat and reflux for 1 hour to dissolve and form an oil phase. Weigh 15g of ammonium bicarbonate and dissolve in 100ml of water, and dissolve at room temperature until completely dissolved to form an aqueous phase. The water phase and the oil phase are mixed at a volume ratio of 1:4 and homogenized at a speed of 2500 rpm to form a viscous emulsion. Quickly insert glass rods with diameters of 2.5mm, 3.5mm, and 4.5mm into the emulsion, and immediately take them out after stirring and dry them at room temperature for 12 hours, then freeze-dry the samples to remove organic solvents, and obtain porous polymer Urethral repair stent.

[0045] The obtained polymeric porous urethral repair scaffold has good toughness, moderate stretching, curling o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com