Magnetic field response spherical microcapsulate with secondary structure, and preparation method thereof

A secondary structure, microcapsule technology, applied in the field of composite materials, can solve the problems of unstable structure and lack of force of ferric oxide, and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of magnetic polymer microspheres

[0023] Dissolve 0.04g isoalcohol diester maleate in 40mL deionized water, stir for 30 minutes, add 0.4g oleic acid modified ferric oxide, 2mL styrene, 0.02g ammonium persulfate, heat up to 65°C and react for 24 hours. A nano-scale magnetic polymer microsphere emulsion is obtained. The particle size measured by dynamic light scattering is about 80nm; the microsphere structure is as follows figure 1 shown.

[0024] (2) Preparation of magnetic field-responsive spherical microcapsules with hierarchical structure

[0025] Take 1mL magnetic polymer microsphere emulsion and dissolve it in 10mL water / ethanol solution (the ethanol content is 15wt%), add 50mL toluene and stir at 40°C for 1 hour, then transfer to an ice-water bath and continue stirring for 30 minutes to obtain magnetic field-responsive spherical Microcapsules.

[0026] (3) Magnetic Response Properties of Magnetic Field Responsive Spherical Microcapsules with M...

Embodiment 2~4

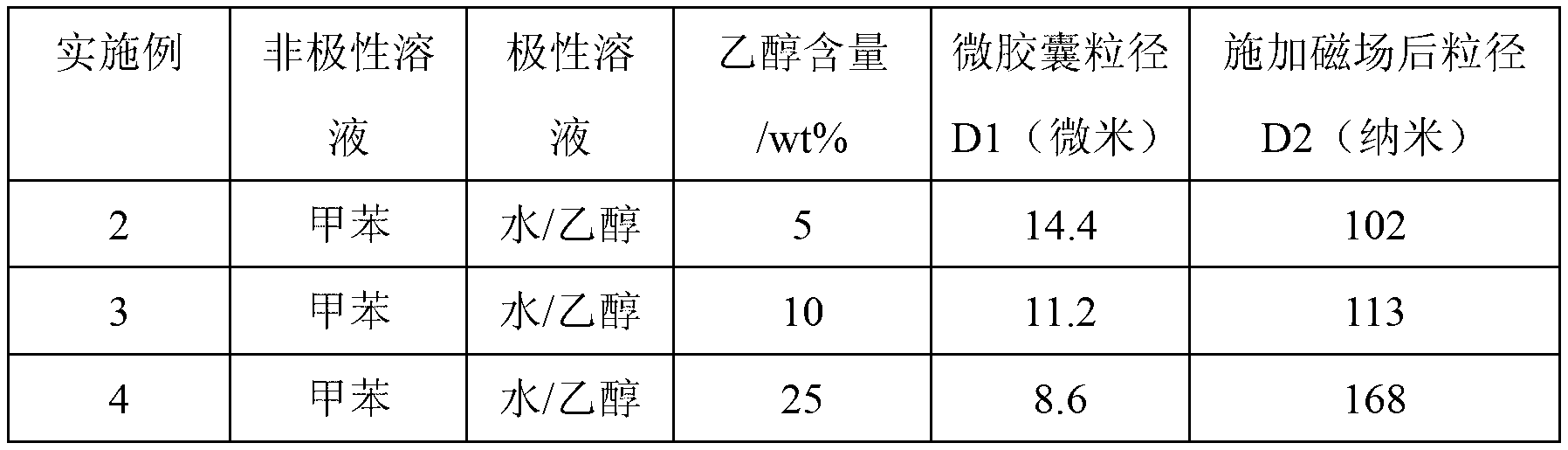

[0029] The same process as in Example 1, but changing the ethanol content in (2) to 5wt%, 10wt%, and 25wt%, respectively, the results are shown in Table 1.

Embodiment 5~9

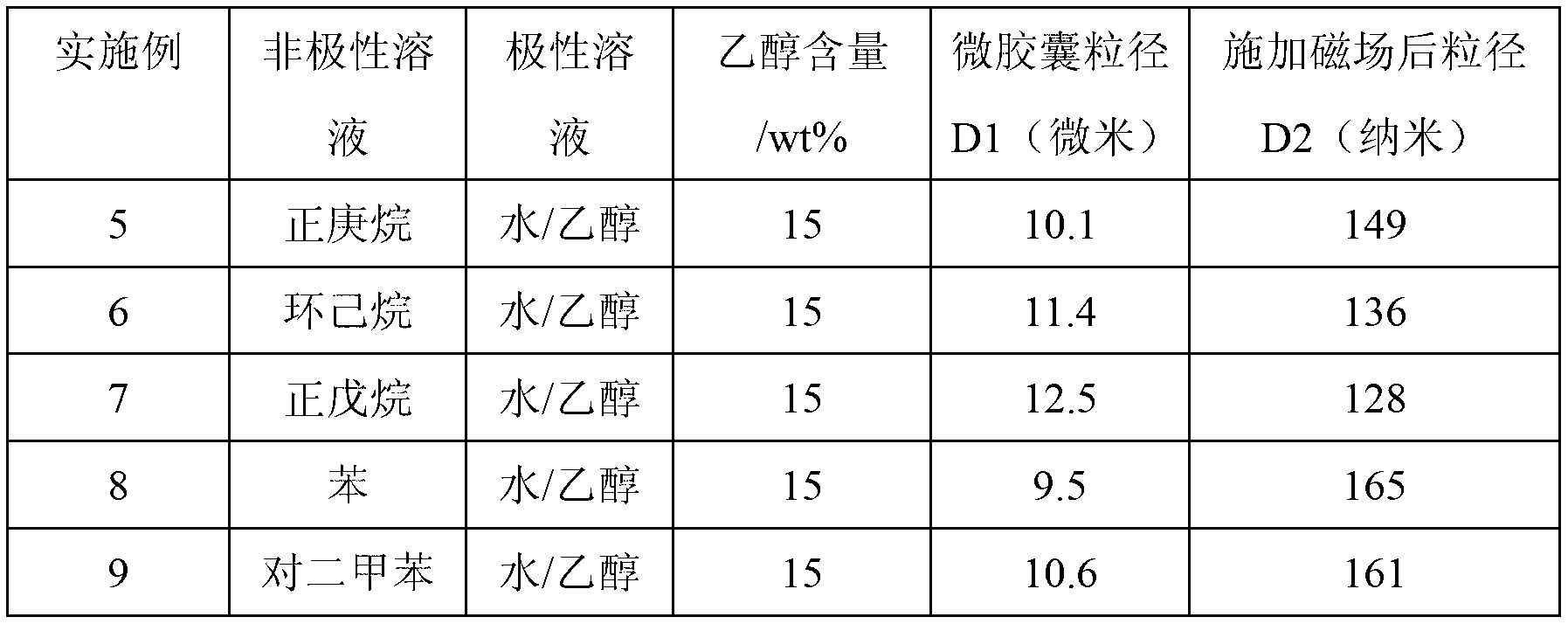

[0031] The process is the same as in Example 1, except that the toluene in (2) is changed to n-heptane, cyclohexane, n-pentane, benzene, and p-xylene, and the results are shown in Table 2.

[0032] Table 1: Table 1 is the result of Examples 2-4.

[0033]

[0034] Table 2: Table 2 is the result of embodiment 5~9.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com