Pharmaceutical composition of lipid-soluble vitamin and preparation method thereof

A technology of fat-soluble vitamins and vitamins, which is applied in (II) and its preparation, and in the field of fat-soluble vitamin injections (I), which can solve problems such as the stability and resolubility to be improved, and the large amount of excipients, so as to achieve enhanced safety performance and reduced Impurities, improve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of vitamin A palmitate crystal compound is as follows: under nitrogen protection, vitamin A palmitate is dissolved in a mixed solvent of chloroform and petroleum ether at 1 °C, and the volume ratio of the mixed solvent of chloroform and petroleum ether is 3:1 , add isopropanol while stirring and cool down to -10°C, the ratio of the volume of added isopropanol to the volume of the mixed solvent of chloroform and petroleum ether is 1:1, the cooling speed is 0.5°C / min, and the stirring speed is 45 rpm / min; stand at 5°C for crystal growth for 5 hours, filter, wash, and vacuum-dry at 5°C to obtain a light yellow crystalline powder of vitamin A palmitate, and obtain vitamin A palmitate for low-temperature storage.

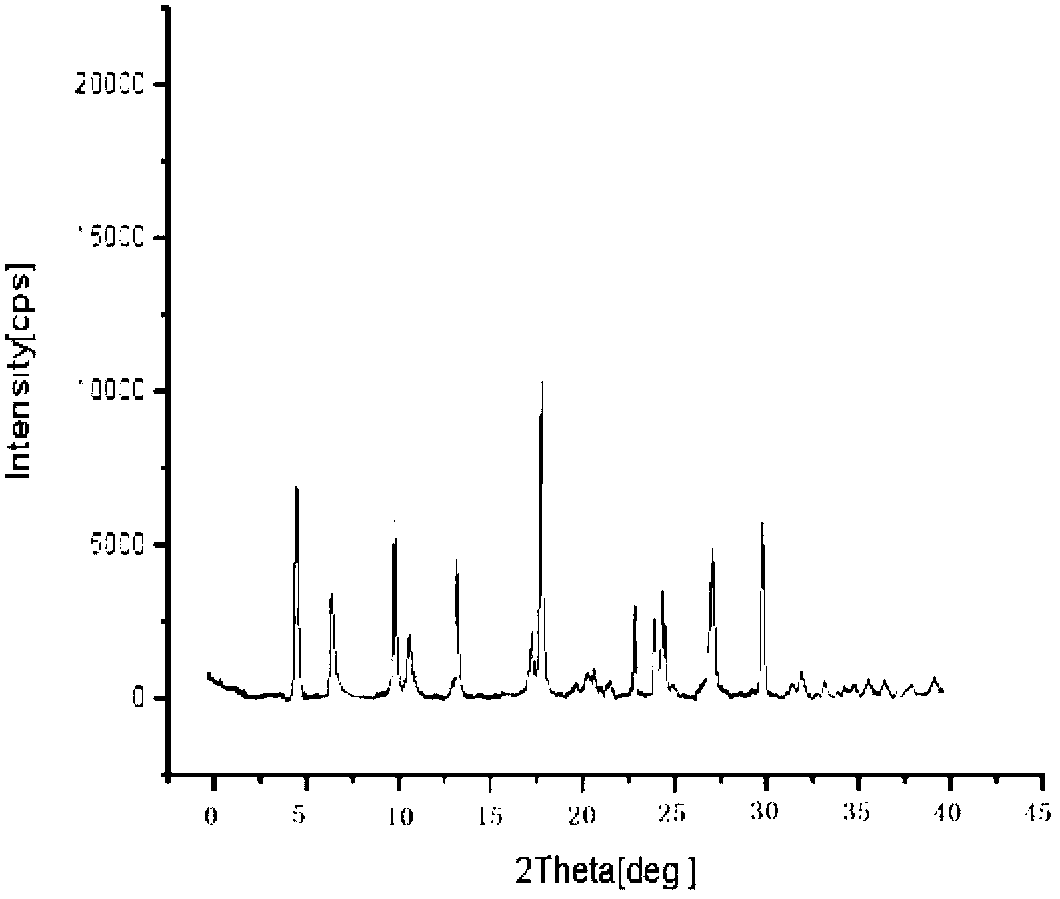

[0039] The compound crystal is detected by high-performance liquid chromatography, and the purity is 99.85%, and the yield is 97.3%; the X-ray powder diffraction pattern obtained by using Cu-Kα ray measurement is as follows: figure 1 shown....

Embodiment 2

[0041] The preparation method of vitamin A palmitate crystal compound is as follows: under nitrogen protection, vitamin A palmitate is dissolved in a mixed solvent of chloroform and petroleum ether at 2°C, and the volume ratio of the mixed solvent of chloroform and petroleum ether is 2:1 , add isopropanol while stirring and lower the temperature to -5°C, the ratio of the volume of added isopropanol to the volume of the mixed solvent of chloroform and petroleum ether is 1:3, the speed of cooling is 1.5°C / min, and the stirring speed is 30 rpm / min; stand at 5°C for crystal growth for 5 hours, filter, wash, and vacuum-dry at 5°C to obtain a light yellow crystalline powder of vitamin A palmitate, and obtain vitamin A palmitate for low-temperature storage.

[0042] The compound crystal is detected by high-performance liquid chromatography, and the purity is 99.84%, and the yield is 97.5%; the X-ray powder diffraction pattern obtained by using Cu-Kα ray measurement is as follows: fi...

Embodiment 3

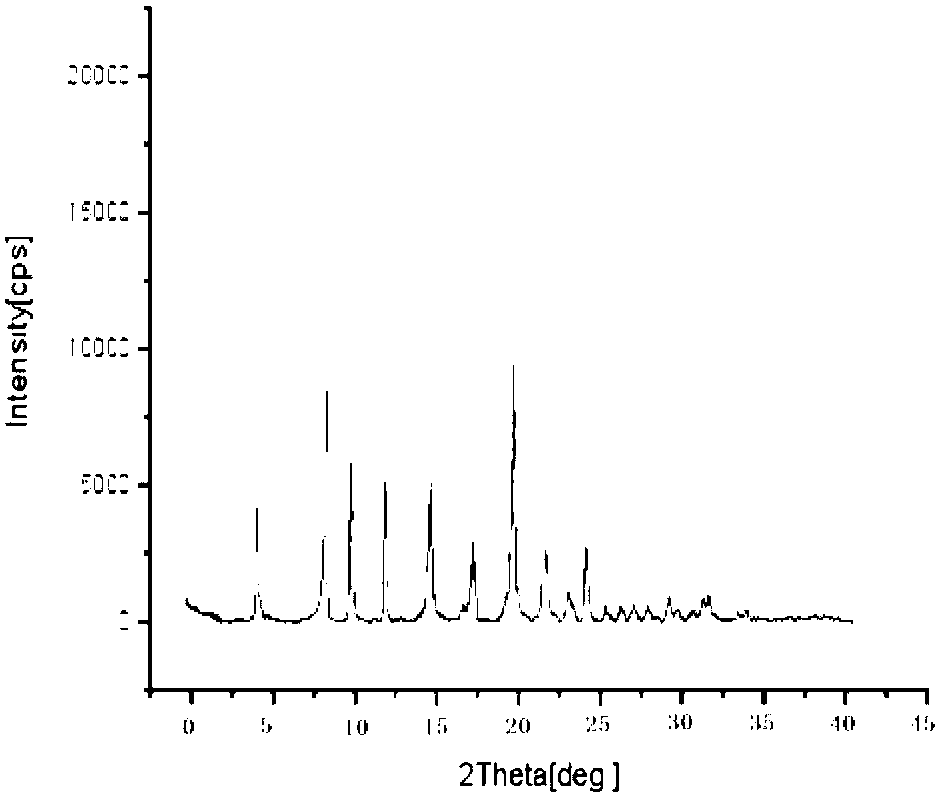

[0044] Vitamin D 2 The preparation method of the crystalline compound is as follows: under nitrogen protection, vitamin D 2 Dissolve in a mixed solution of acetone and ethyl acetate at -5°C, the volume ratio of acetone and ethyl acetate is 3:1; add double distilled water at 5°C while stirring under nitrogen, and the stirring speed is 90 rpm; The ratio of the volume of double-distilled water to the volume of the mixed solution of acetone and ethyl acetate is 1:1; let the crystal grow for 5 hours, filter, wash, and vacuum-dry to obtain vitamin D 2 white crystalline powder. The compound was detected by high performance liquid chromatography, the purity was 99.97%, and the yield was 97.2%. The X-ray powder diffraction pattern obtained by Cu-Kα ray measurement is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com