Novel maltooligosyl trehalose synthase, gene of synthase, recombinant expression vector containing gene, and recombinant bacterium, and preparation of synthase

A trehalose synthase and malto-oligosaccharide-based technology, which is applied in the fields of genetic engineering and enzyme engineering, can solve the problems of low double-enzyme activity and easy contamination, and achieves the advantages of reduced enzyme cost, simple bacterial culture, and difficult bacterial contamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 bacterial cell culture

[0082] After extensive screening, Arthrobacter oxydans TL-3 with good activity of MTSase and MTHase was selected, and the strain was deposited in the American Type Culture Collection (ATCC) with the deposit number: 14358. The medium composition of the strain is: peptone 10 g / L, yeast extract 30 g / L, glucose 10 g / L, MgSO 4 0.06 g / L, KH 2 PO 4 2.13 g / L, K 2 HPO 4 ·3H 2 O 16.43 g / L, pH 7.0. Heat sterilization at 121°C for 15 min.

[0083] The process of cell culture is as follows: After the culture medium is cooled, two rings are taken from the slant bacteria. A . oxydans TL-3 cells were inoculated into a 1000 mL Erlenmeyer flask filled with 200 mL of the above-mentioned medium, and cultured with shaking at 220 rpm and 38°C for 24 h.

Embodiment 2

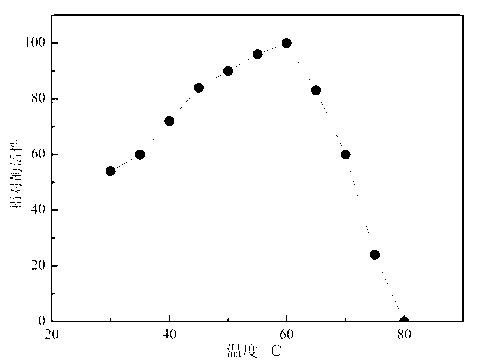

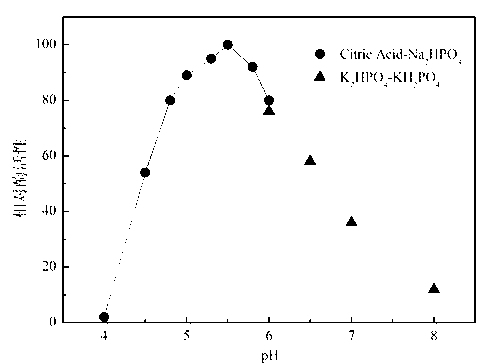

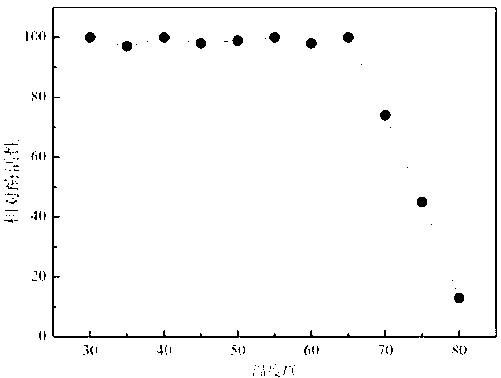

[0084] Example 2 MTSase separation and purification and enzymatic characteristics research

Embodiment 2-1

[0085] Embodiment 2-1 MTSase separation and purification

[0086] (1) Bacterial fragmentation

[0087] Carry out bacterial cell culture according to the method in Example 1, obtain 10 liters of culture, centrifuge at 8000 rpm for 20 min, harvest 150 g of wet bacterial cells, resuspend in buffer, and sonicate the bacterial cells in an ice bath. The buffer composition is 0.2 Mol / L citrate buffer, pH5.5. Centrifuge (10000 r / min, 20 min) after sonication, and take the supernatant to obtain the crude enzyme solution.

[0088] (2) Ammonium sulfate precipitation

[0089] Both ammonium sulfate precipitation and dialysis were carried out in an ice bath. Ammonium sulfate was slowly added to the crude enzyme solution to make the saturation reach 40%, and left overnight at 4°C, then centrifuged at 12000 r / min for 20 min, and sulfuric acid was slowly added to the supernatant Ammonium was used to make the saturation to 60%, centrifuged again, the precipitate was collected and dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com