Application of Lactobacillus casei fermentation liquor to feeds

A technology of Lactobacillus casei and fermentation liquid, applied in the field of bio-fermentation technology and feed, to achieve good antibacterial activity, good antibacterial effect, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Study on Fermentation Conditions and Fermentation Technology of Lactobacillus Casei

[0045] 1.1 Optimization of fermentation conditions under laboratory conditions

[0046] 1.1.1 Determination of growth curve

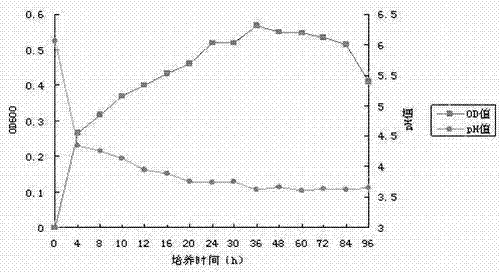

[0047] Firstly, the growth curve and acid production curve of Lactobacillus casei (T1) were measured, the results are as follows: figure 1 .

[0048] From figure 1 It can be seen that Lactobacillus casei T1 entered the logarithmic growth phase at about 4 h, entered the stable phase at 36 h, and began to decline after 84 h. It can be seen from the acid production curve that within the range of 1-4 h, the pH has dropped significantly, which shows that T1 has started to grow before 4 h, and its lag period is less than 4 h. It can be seen from the acid production curve that the acid production capacity of T1 is relatively strong, and the pH has dropped to 4.35 at 4 h. With the rapid growth of the bacteria, the pH gradually decreased, and at the end o...

Embodiment 2

[0091] Example 2 Study on the effect of adding bacteriocin high-yield strains to feed

[0092] 2.1 Antibacterial effect of bacteriocin crude extract added to feed

[0093] 2.1.1 Bacteriostatic effect under normal conditions

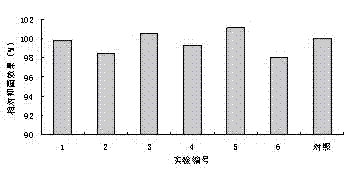

[0094] Add 2.5 mg, 5 mg, and 10 mg of bacteriocin crude extract to each 1000 g of feed to determine the antibacterial effect under conventional conditions. The results show that the antibacterial effect is the best when the added amount is 10 mg. see attached results Figure 4 .

[0095] 2.1.2 Bacteriostatic effect under enhanced conditions

[0096] Add 2.5mg, 5mg, and 10mg of bacteriocin crude extract to each 1000g feed to determine the antibacterial effect under enhanced conditions. The results show that the antibacterial effect is the best when the added amount is 10mg. see attached results Figure 5 .

[0097] 2.1.3 Comparison of the effect of the crude extract of bacteriocin and the positive control

[0098] Under conventional conditions and...

Embodiment 3

[0103] Example 3 Study on large-scale production technology of Lactobacillus casei feed additive

[0104] 3.1 Batch fermentation test under pilot test conditions

[0105] Continuous fermentation trial production was carried out in a 10-ton fermenter, 10 batches of continuous fermentation were produced, and nearly 10 tons of Lactobacillus casei powder was produced. The continuous fermentation production proved that the production performance of the strain was stable, the fermentation production process was mature, and the fermentation was 48 hours. The concentration of Lactobacillus casei in the fermentation broth was 1.4×10 9 Viable bacteria / ml, then take Staphylococcus aureus as indicator bacteria, oxytetracycline as reference substance, measure the bacteriocin titer in the fermented liquid, the measuring result shows, the bacteriocin titer in the fermented liquid is equivalent to 3.4×10 5 units of oxytetracycline / mL. The fermented liquid is spray-dried, and then the Lact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com