Method for preparing silver nanowires

A technology of silver nanowires and silver salts, applied in the field of preparing silver nanowires, can solve the problems of long heating and cooling process, difficulty in preparing silver nanowires, high energy consumption, etc., and achieve the advantages of convenient operation, simple process and low surface resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

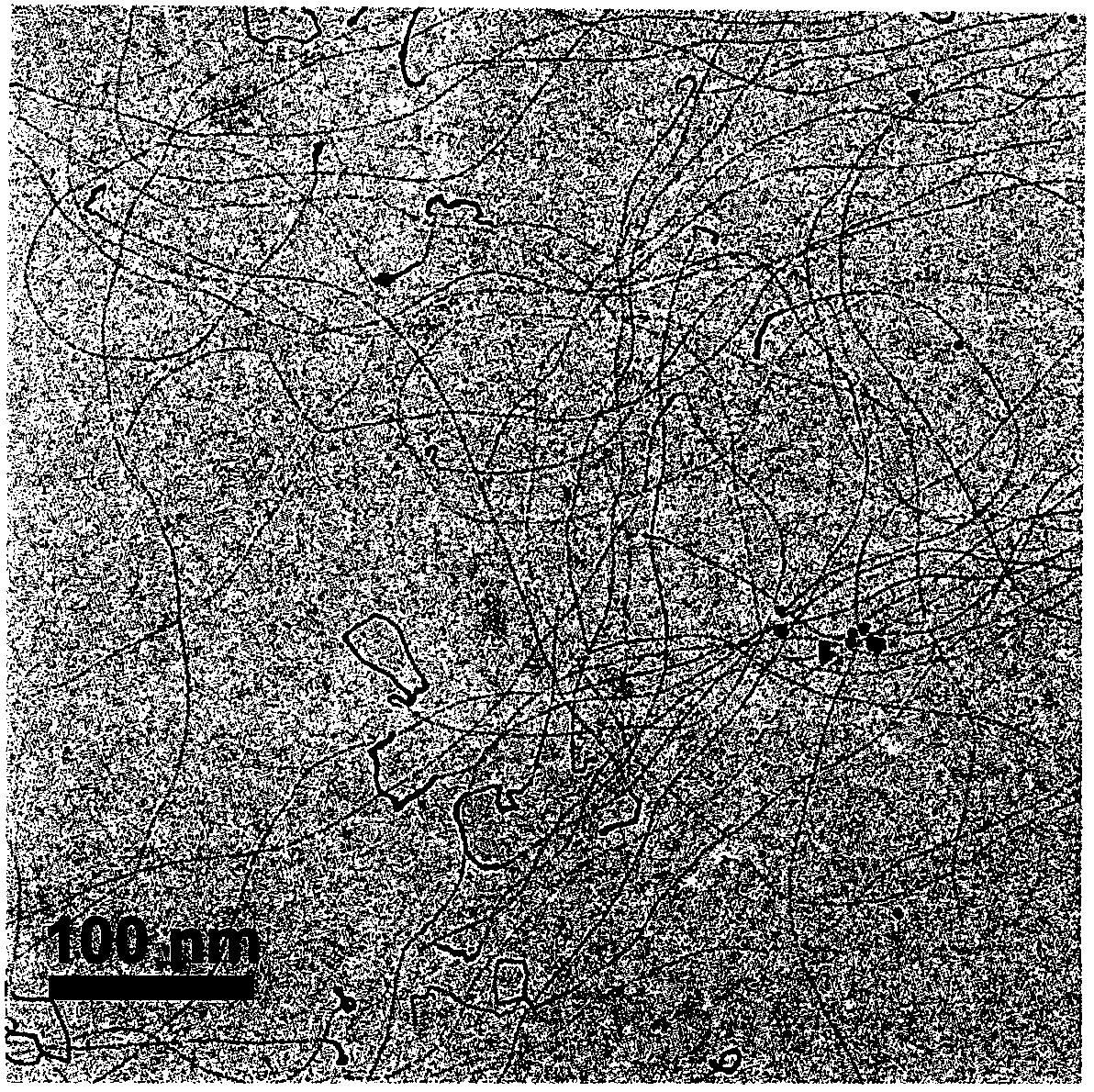

[0039] A method for preparing silver nanowires, comprising the steps of: (1) preparing a mixed solution of dimethylformamide, water, ascorbic acid and polyvinylpyrrolidone earlier: get 1 gram of ascorbic acid and add it to 50 milliliters of dimethylformamide and In the water mixed solvent (the volume ratio of dimethylformamide and water is 1:1), after stirring or ultrasonically dissolving, add polyvinylpyrrolidone, stir or ultrasonically dissolve to obtain mixed solution A; (2) take 1 gram of silver nitrate Add 25 ml of ethylene glycol, stir or oscillate to dissolve, then add 0.005 g of chloroauric acid, and mix thoroughly to obtain mixed solution B; (3) Mix mixed solution A and mixed solution B evenly, then place in a dark room and stir Keep it under the pressure for 4 hours, stop stirring to get the silver nanowire stock solution; (4) dilute the silver nanowire stock solution 5 times with a mixed solvent composed of water and ethanol, then centrifuge at a speed of 10000 rpm f...

Embodiment 2

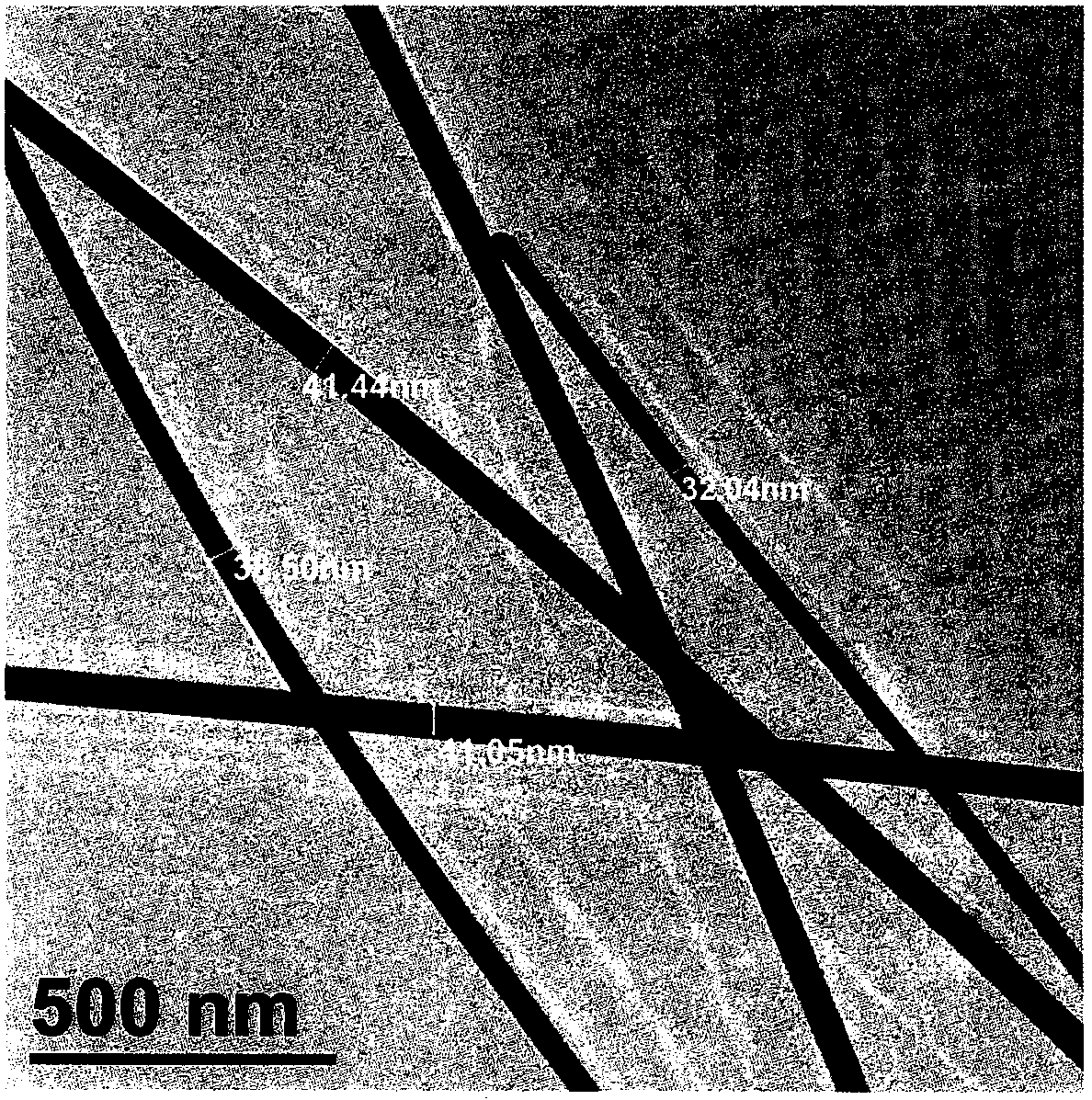

[0042]On the basis of Example 1, in the preparation process, the consumption of silver nitrate in step (2) is promoted to 3 grams, and chloroauric acid is replaced with chloroplatinic acid, and the centrifugation speed in step (4) is reduced to 6000 rpm The silver nanowires with a diameter of 40 nanometers were prepared while other process parameters remained unchanged.

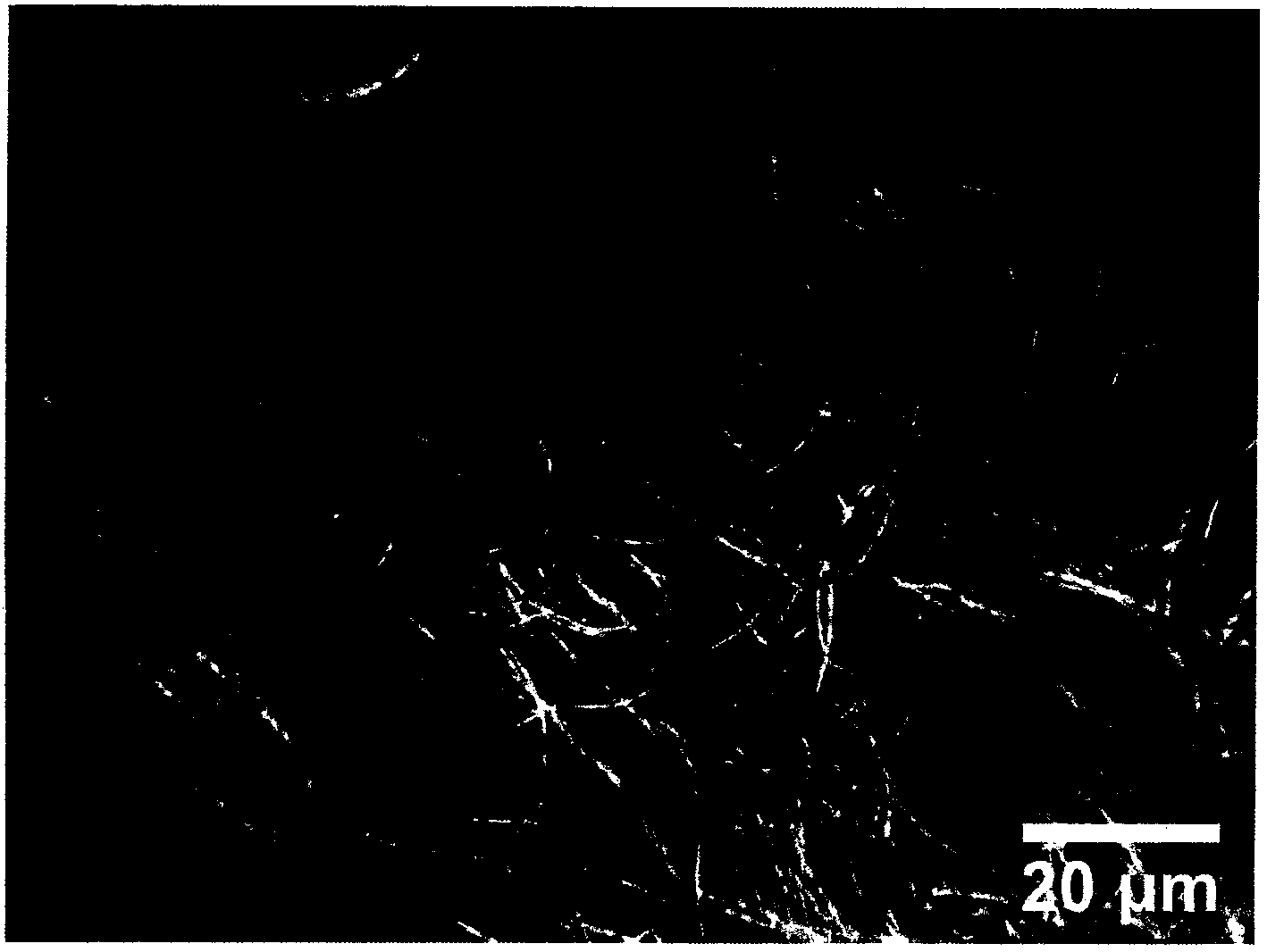

[0043] figure 2 The transmission electron micrograph of the silver nanowire powder product that this embodiment makes, by figure 2 It can be seen that the diameter distribution is narrow. image 3 It is an optical microscope photo of the product. It can be seen from the figure that the obtained silver nanowires are evenly distributed, and the length is about 30-40 microns, and there is no agglomeration phenomenon. The transparent conductive film prepared based on this product has the characteristics of high flexibility, high light transmittance, and low sheet resistance.

Embodiment 3

[0045] On the basis of embodiment 1, in the preparation process, ethylene glycol is replaced with glycerol in step (2), the consumption of silver nitrate is promoted to 3.5 grams, and chloroauric acid is replaced with ferric chloride, and other processing parameters remain unchanged Change, and prepare silver nanowires with a diameter of 70 nm.

[0046] Figure 4 The scanning electron microscope picture of the silver nanowire powder product that is made in this embodiment, Figure 5 An optical microscope photograph of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com