Method for preparing tegafur, gimeracil and oteracil potassium capsules

A capsule preparation and capsule technology, which is applied in the field of medicine, can solve the problems that are not conducive to labor protection, the disintegrating agent is easy to absorb moisture, and the dust is large, so as to achieve the effects of being beneficial to labor protection, improving drug dissolution, and avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

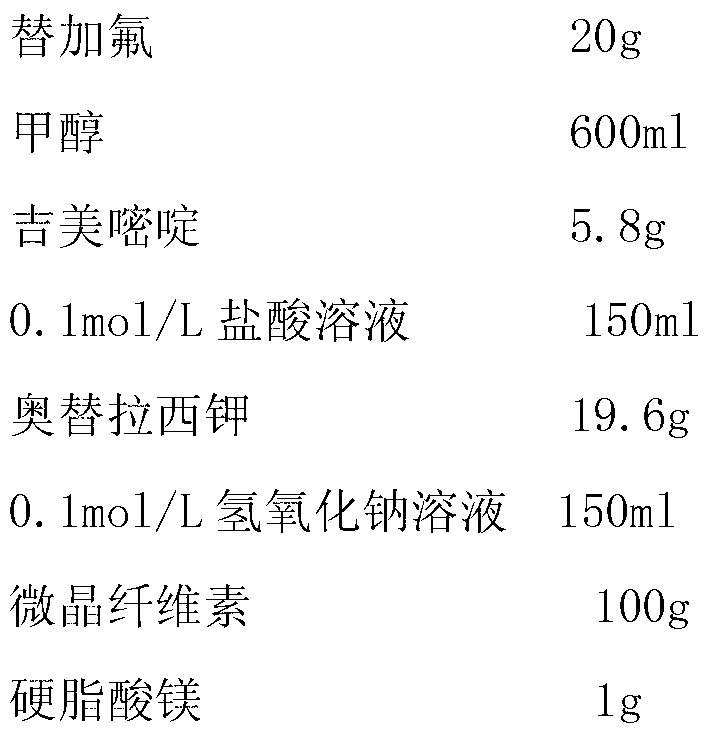

[0030]

[0031] Preparation Process:

[0032] (1) Tegafur was dissolved in methanol, gimeracil was dissolved in hydrochloric acid solution, oteracil potassium was dissolved in sodium hydroxide solution;

[0033] (2) After mixing the three solutions quickly, quickly add microcrystalline cellulose and stir to obtain nanoscale drugs attached to the microcrystalline cellulose;

[0034] (3) Dry the drug-containing granules at 60°C, and sieve the granules with 20 meshes;

[0035] (4) Add magnesium stearate to the dry granules, mix well, and pack into capsules.

Embodiment 2

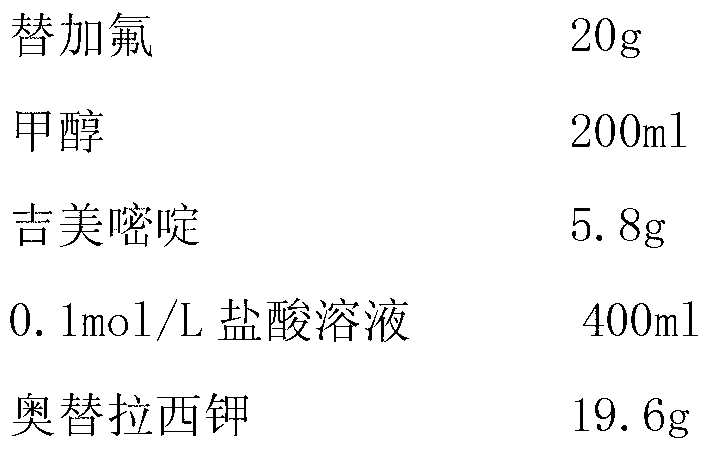

[0037]

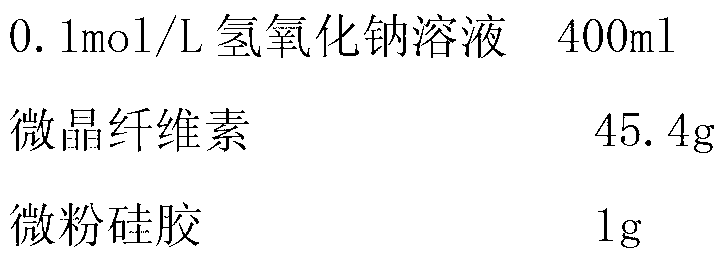

[0038]

[0039] Preparation Process:

[0040] (1) Tegafur was dissolved in methanol, gimeracil was dissolved in hydrochloric acid solution, oteracil potassium was dissolved in sodium hydroxide solution;

[0041] (2) After mixing the three solutions quickly, quickly add microcrystalline cellulose and stir to obtain nanoscale drugs attached to the microcrystalline cellulose;

[0042] (3) Dry the drug-containing granules at 60°C, and sieve the granules with 20 meshes;

[0043] (4) Add micropowder silica gel to dry granules, mix well, and put into capsules.

Embodiment 3

[0045]

[0046] Preparation Process:

[0047] (1) Tegafur was dissolved in methanol, gimeracil was dissolved in hydrochloric acid solution, oteracil potassium was dissolved in sodium hydroxide solution;

[0048] (2) After mixing the three solutions quickly, quickly add microcrystalline cellulose and stir to obtain nanoscale drugs attached to the microcrystalline cellulose;

[0049] (3) Dry the drug-containing granules at 60°C, and sieve the granules with 20 meshes;

[0050] (4) Add magnesium stearate to the dry granules, mix well, and pack into capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com