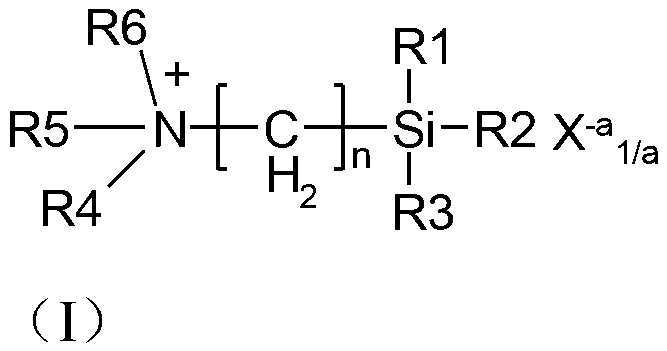

Preparation method of poly siloxane quaternary ammonium modified zeolite and application thereof

A technology of polysiloxane and quaternary ammonium salt, which is applied in the direction of botany equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of short service life and decreased release of surface active components, and achieve long service life and strong The effect of adsorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

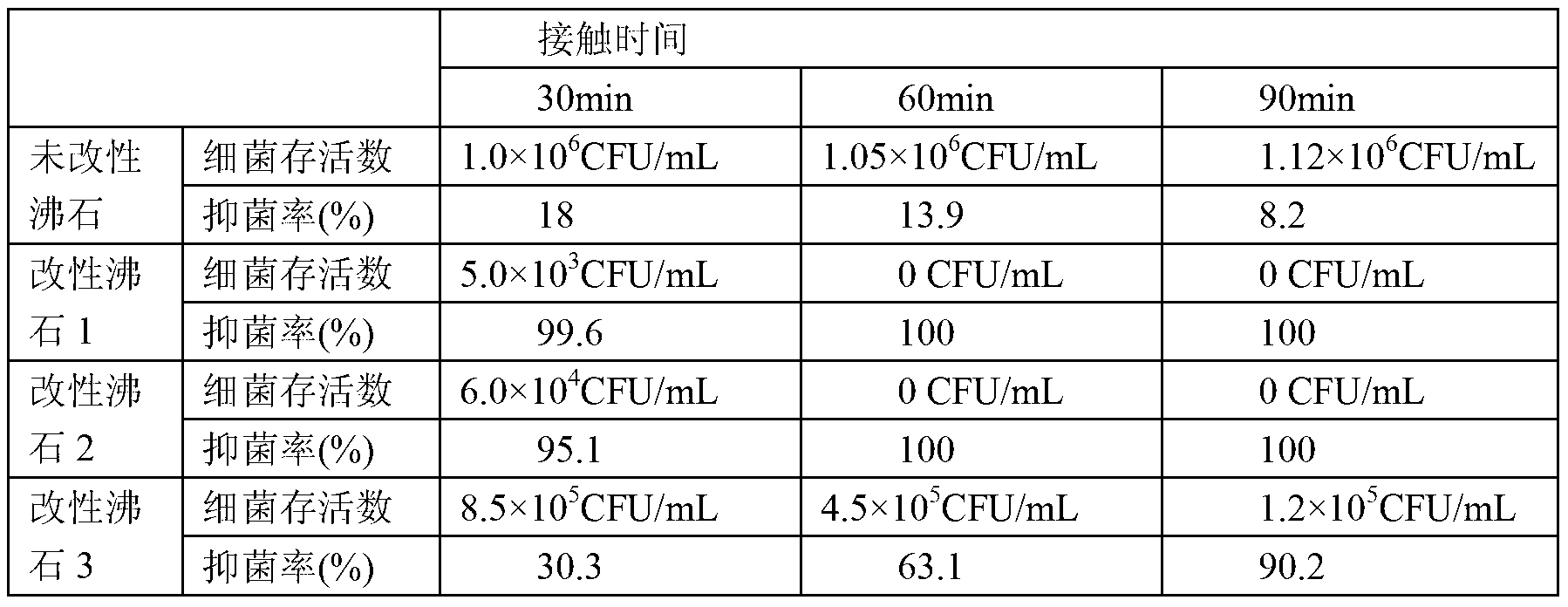

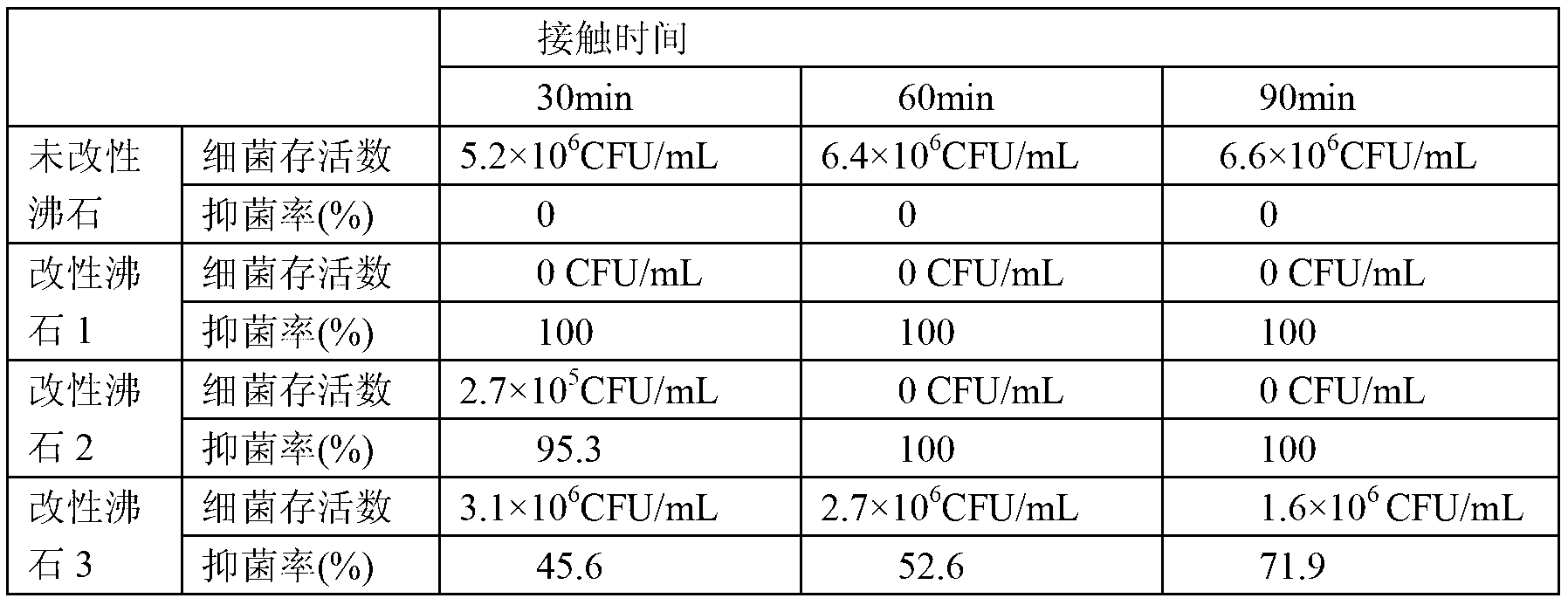

Examples

Embodiment 1

[0027] This example is the preparation of polysiloxane quaternary ammonium salt modified zeolite (1)

[0028] In situ polymerization of 3-(trimethoxysilyl)propylcetyldimethylammonium chloride on zeolite surfaces.

[0029] Weigh 0.50g of 3-(trimethoxysilyl)propylhexadecyldimethylammonium chloride and add it into a 250mL conical flask with a stopper, add 37.00mL of deionized water, after ultrasonic dissolution, add 10.00 g zeolite, after shaking at room temperature for 30min, add 3.00mL of 4.00mol / L hydrochloric acid solution, adjust the concentration of hydrochloric acid solution to 0.30mol / L, and place it in a 50°C constant temperature shaking water tank to react for 6h. After the reaction is completed, wash it with deionized water Until the solution is clear, place it in a blast drying oven at 90°C for 2 hours to obtain polysiloxane quaternary ammonium salt-modified zeolite, and the number of moles of quaternary ammonium salt functional groups per gram of zeolite is 1.07×10 ...

Embodiment 2

[0031] This example is the preparation of polysiloxane quaternary ammonium salt modified zeolite (2)

[0032] In situ polymerization of 3-(trimethoxysilyl)propylcetyldimethylammonium chloride on zeolite surfaces.

[0033] Weigh 0.20g of 3-(trimethoxysilyl)propylhexadecyldimethylammonium chloride and add it into a 250mL conical flask with a stopper, add 37.00mL of deionized water, after ultrasonic dissolution, add 10.00g of zeolite, after shaking at room temperature for 30min, add 3.00mL of 4.00mol / L hydrochloric acid solution, adjust the concentration of hydrochloric acid solution to 0.30mol / L, and place it in a 50°C constant temperature shaking water tank for 6h. After the reaction is completed, rinse with deionized water Wash until the solution is clear, and dry it in a blast drying oven at 90°C for 2 hours to obtain polysiloxane quaternary ammonium salt-modified zeolite, and the number of moles of quaternary ammonium salt functional groups per gram of zeolite is 4.29×10 -5...

Embodiment 3

[0035] This example is the preparation of polysiloxane quaternary ammonium salt modified zeolite (3)

[0036] In situ polymerization of 3-(trimethoxysilyl)propylcetyldimethylammonium chloride on zeolite surfaces.

[0037] Weigh 0.10g of 3-(trimethoxysilyl)propylhexadecyldimethylammonium chloride and add it into a 250mL conical flask with a stopper, add 37.00mL of deionized water, after ultrasonic dissolution, add 10.00g of zeolite, after shaking at room temperature for 30min, add 3.00mL of 4.00mol / L hydrochloric acid solution, adjust the concentration of hydrochloric acid solution to 0.30mol / L, and place it in a 50°C constant temperature shaking water tank for 6h. After the reaction is completed, rinse with deionized water Wash until the solution is clear, and dry it in a blast drying oven at 90°C for 2 hours to obtain polysiloxane quaternary ammonium salt modified zeolite, and the number of moles of quaternary ammonium salt functional groups per gram of zeolite is 2.14×10 -5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com