Method for recycling and purifying ionic liquid in mixed solution

A technology of mixing solutions and ionic liquids, applied in organic chemistry and other fields, can solve the problems of low purity of ionic liquids, water pollution, recycling fees, etc., and achieve the effects of large-scale application, high recycling efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

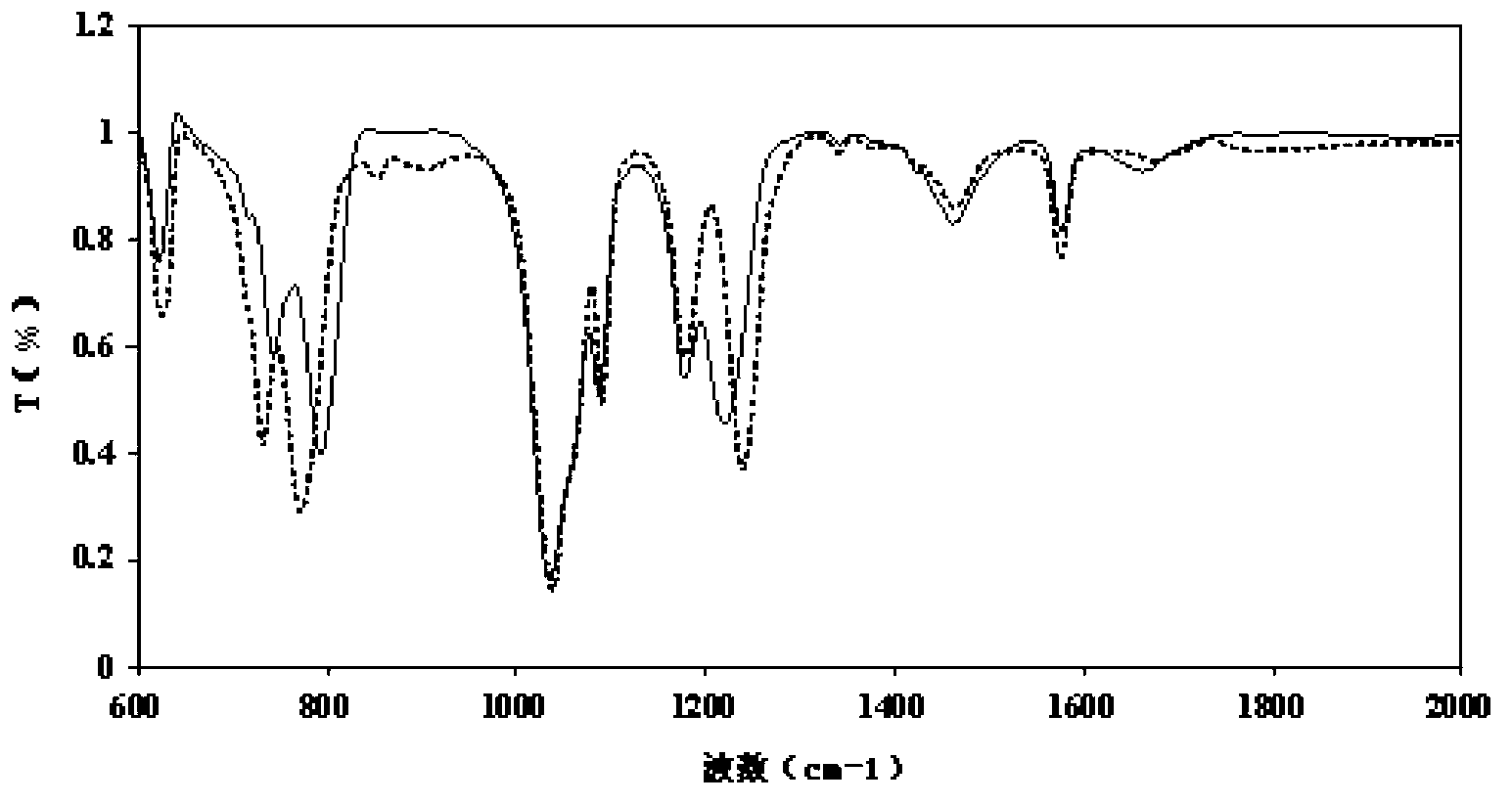

Image

Examples

Embodiment 1

[0018] 1) In situ degradation of straw by ionic liquid / cellulase: use ionic liquid 1-ethyl-3-methylimidazolium diethylphosphate [EMIM]DEP to treat corn straw at 130°C, cool it in ionic liquid Add water and cellulase enzyme powder to the solution, adjust the pH to 2.0 with ammonia water, so that the final concentration of ionic liquid is 5.0% (v / v), and the final concentration of cellulase is 12.5 FPU / mL.

[0019] 2) Construction of the reverse micellar system: Take 2ml of xylene and 4ml of n-hexanol to dissolve in the test tube, weigh 0.97g Triton X-100 solution and dissolve it in the mixture of xylene and n-hexanol, and shake the test tube until the test tube There is no colorless transparent layered liquid at the bottom, and the mixed solution is clear and transparent, then add 27μml pH=5.8 enzyme buffer solution to the mixed solution, then get ωo=1, 250mmol / L Triton X-100 / xylene, n-hexane Alcohol (1:2, v / v) reverse micellar solution.

[0020] 3) Recovery and purification o...

Embodiment 2

[0023] 1) Ionic liquid / cellulase in situ enzymatic hydrolysis of straw: use ionic liquid 1-methyl-3-methylimidazolium diethylphosphate ([MMIM]DEP) to treat bagasse at 100°C, after cooling Add citrate buffer and cellulase enzyme powder to the ionic liquid, adjust the pH=4.8, make the final concentration of ionic liquid 20% (v / v), and the final concentration of cellulase 13FPU / mL.

[0024] 2) Construction of the reverse micellar system: Weigh 2.2228g of di-isooctyl sulfonate sodium succinate (AOT) into a beaker, dissolve it with 2,2,4-trimethylpentane (iso-octane), and transfer it to Dilute to volume in a 100ml volumetric flask, fully shake until the solution in the bottle is colorless and transparent, and then drop 0.9g of distilled water to obtain an AOT / isooctane reverse micelle system with ωo=10, 50mmol / L.

[0025] 3) Recovery of ionic liquid by the reverse micellar system: the cellulase in the mixed system of cellulase and ionic liquid (20%, v / v) was removed by the reverse ...

Embodiment 3

[0027] 1) Ionic liquid / cellulase in situ enzymatic hydrolysis of straw: use ionic liquid 1-methyl-3-methylimidazolium diethylphosphate ([MMIM]DEP) to treat bagasse at 100°C, after cooling Add citrate buffer and cellulase enzyme powder to the ionic liquid, adjust the pH=10, make the final concentration of ionic liquid 30% (v / v), and the final concentration of cellulase 13FPU / mL.

[0028] 2) Construction of reverse micellar system: Weigh 0.25g of CTAB, add organic solvent (6.5mL of isooctane, n-hexane

[0029] The amount of alcohol added is 0.2mL) to form an emulsion, and then add 0.15ml of enzyme-containing phosphate buffer at pH 7.5 while shaking to form a uniform, transparent and clear CTAB / isooctane / n-Hexanol reverse micellar system.

[0030]3) Recovery of ionic liquid by the reverse micellar system: the cellulase in the mixed system of cellulase and ionic liquid (30%, v / v) was removed by using the reverse micellar system, in which the amount of the reverse micellar soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com