Conduit for tissue-engineered nerve transplanting and preparation method thereof

A nerve transplantation and tissue engineering technology, applied in the field of nerve transplantation catheter and its preparation, can solve problems such as limited application, and achieve the effect of promoting axon growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of this specific embodiment is:

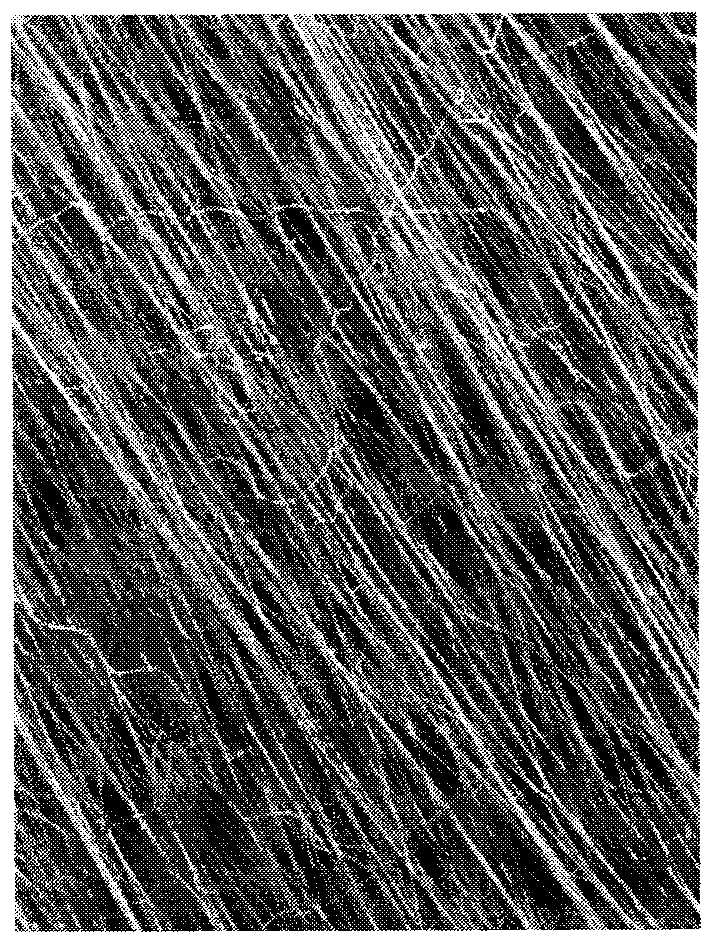

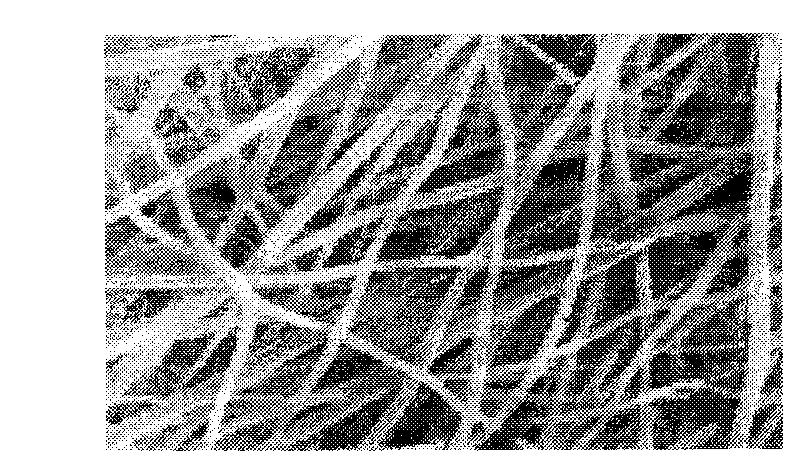

[0031] (1) Preparation of oriented nanofiber layer:

[0032]a. Weigh one or more of silk fibroin, collagen, gelatin, laminin and fibrinogen, and dissolve in one or more solvents in formic acid, hexafluoroisopropanol and hexafluoroacetone to obtain 9- 15% spinning dope; it can also be synthesized by one or more of poly-L-lactic acid (PDLA), polyglycolic acid (PGA) or a copolymer of glycolic acid and hydroxypropionic acid (PLGA) with a higher proportion of GA The polymer is dissolved in one or more solvents of 2,2,2-trifluoroethanol, hexafluoroisopropanol, chloroform, dichloromethane, tetrahydrofuran (THF), acetone, and dimethylformamide , forming a 3-8% spinning dope.

[0033] b. Inhale the spinning stock solution in step a into the injection needle, and put the injection needle in the micropump to control the feeding speed of the spinning solution. The positive pole of the high-voltage power generator is connect...

Embodiment 1

[0041] 1. Weigh 4.4g regenerated silk fibroin film and 2.1g medical gelatin and dissolve in anhydrous formic acid to obtain 11.5% silk fibroin / gelatin blended spinning solution. Weigh 2g of polyglycolic acid (PGA) and 1g of L-polyhydroxypropionic acid (PLLA) and dissolve them in tetrahydrofuran (THF) to form a 4% spinning solution. 2.5g of L-polyhydroxypropionic acid (PLLA) was dissolved in chloroform / acetone (volume ratio 1:1) mixed solvent to obtain 4.9% spinning solution;

[0042] 2. Inhale the silk fibroin / gelatin spinning solution prepared in step 1 into a needle tube, put the needle tube in a micropump, and adjust the flow rate to 0.1ml / h. The positive electrode of the high-voltage generator is connected to the needle head, and the voltage is 15kV. The negative electrode is connected to the metal wires arranged in parallel on the rotating roller. The direction of the wire arrangement is parallel to the axial direction of the rotating roller. The distance between the nee...

Embodiment 2

[0047] 1. Weigh 2 g of racemic polylactic acid (PDLA), dissolve it in 2,2,2-trifluoroethanol to obtain a 3% spinning solution. 1.8g of polyglycolic acid (PGA) and 1.2g of PLGA (LA:GA=60:40) were weighed and dissolved in tetrahydrofuran (THF) to form a 4.2% spinning solution. Dissolve 2g of PLGA (LA:GA=85:15) in a mixed solvent of chloroform / acetone (volume ratio 2:1) to obtain a 5.0% spinning dope;

[0048] 2. Inhale the PDLA spinning solution prepared in step 1 into the needle tube, put the needle tube in the micropump, and adjust the flow rate to 0.13ml / h. The positive electrode of the high-voltage generator is connected to the needle head, the voltage is 15kV, the negative electrode is connected to the metal wires arranged in parallel on the rotating roller, the wire arrangement direction is parallel to the axial direction of the rotating roller, the diameter of the rotating roller is 10cm, and the rotating speed is 4000rpm. The distance between the needle and the collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com