Fischer-Tropsch synthetic catalyst for preparing low-carbon olefin by utilizing synthetic gas, modified molecular sieve carrier and preparation method

A low-carbon olefin and Fischer-Tropsch synthesis technology, applied in the direction of catalyst activation/preparation, carbon compound catalyst, liquid hydrocarbon mixture preparation, etc., can solve the problems of complex preparation process and difficult industrial application, and achieve simple and easy preparation process, The effect of low cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

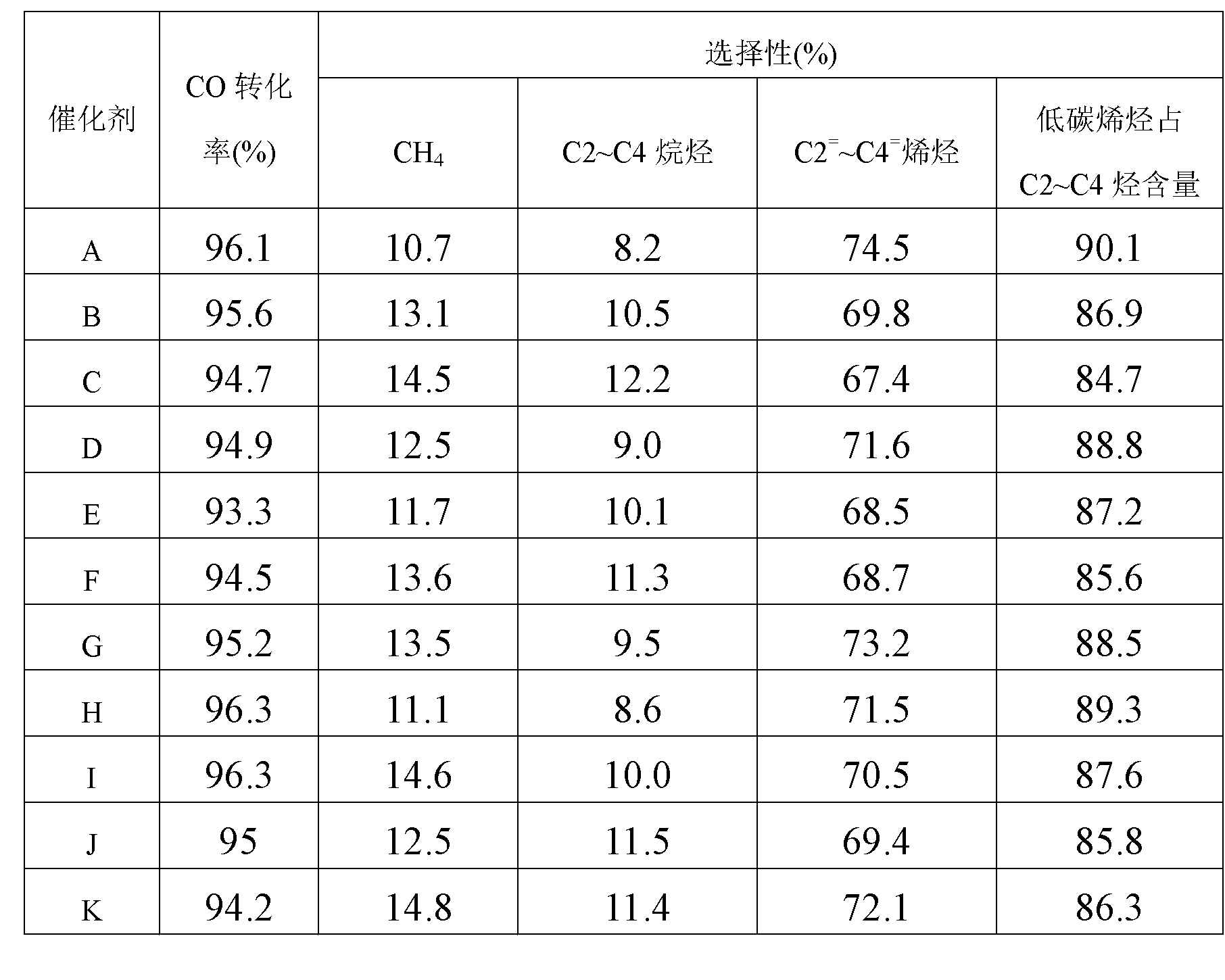

Examples

preparation example Construction

[0030] The preparation of modified molecular sieve comprises the following steps:

[0031] (1) Combine SSZ-13, SAPO-34 silica-alumina molecular sieve or ZSM-5 and other high-silicon molecular sieves with one selected from ammonium sulfate, ammonium nitrate, ammonium chloride, and acetic acid at a temperature of 26-99°C Reflux for 3 to 6 hours, the concentration of the acid solution is 0.05 to 5 mol / L, filter, wash, dry, and roast at a temperature of 700°C for 6 hours to obtain a hydrogen-type molecular sieve;

[0032] (2) Fully mix the hydrogen-type molecular sieve obtained in step (1) with a solution of 0.1-1 mol / L cerium salt (or praseodymium salt) evenly, at a temperature of 25-85°C and a vacuum of 10 -1 ~10 -4 Immerse under Pa condition for 15-30h;

[0033] (3.) Dry the molecular sieve obtained in step (2) at a temperature of 70-150° C. for 15-30 hours, and then calcinate at a temperature of 400-700° C. for 1-8 hours. Prepare the required cerium (or praseodymium) modifi...

Embodiment 1

[0052] Weigh cerium nitrate and SSZ-13 silicon-aluminum molecular sieve according to the mass ratio Ce:molecular sieve=1:9, reflux the molecular sieve and 0.1mol / L ammonium nitrate solution at 80°C for 5h, filter, wash, dry, and roast at 700°C 6h, the obtained hydrogen molecular sieve and cerium nitrate solution were mixed evenly, at 85°C, 10 -4 The modified molecular sieve was obtained by impregnating under Pa vacuum for 24h, then drying at 130°C for 20h, and finally roasting at 550°C for 6h.

[0053] Weigh iron oxalate, manganese nitrate, copper citrate and potassium carbonate according to the mass ratio Fe:Mn:Cu:K=28:5:5:5, use water as solvent to make a solution, add 0.1% surface active of sodium lauryl sulfate and stir. Quantitatively weigh the Ce-modified SSZ-13 silicon-aluminum molecular sieve according to the mass ratio Fe:molecular sieve=7:15, and soak the solution into the molecular sieve under vacuum conditions, mix and stir evenly, dry at 65°C for 4 hours, and the...

Embodiment 2

[0055] Weigh cerium nitrate and SSZ-13 silicon-aluminum molecular sieve according to the mass ratio Ce:molecular sieve=1:19, reflux the molecular sieve and 0.1mol / L ammonium sulfate solution at 80°C for 5h, filter, wash, dry, and roast at 700°C 6h, mix the obtained hydrogen molecular sieve with cerium nitrate solution evenly, -1 The modified molecular sieve was obtained by impregnating for 30 hours under Pa vacuum, then drying at 150°C for 15 hours, and finally roasting at 700°C for 6 hours.

[0056] Weigh ferric nitrate, manganese nitrate, copper nitrate and potassium nitrate according to the mass ratio Fe:Mn:Cu:K=22:6:6:2, make a solution with water as a solvent, and add 0.1% of the solution mass Surfactant sodium lauryl sulfate, stir. Quantitatively weigh the Ce-modified SSZ-13 silicon-aluminum molecular sieve according to the mass ratio Fe:molecular sieve=22:65. Under vacuum conditions, the solution is immersed in the molecular sieve, mixed and stirred evenly, and dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com