Preparation method of polyacrylamide emulsion

A polyacrylamide and acrylamide technology, which is applied in the fields of paper, textiles and papermaking, and non-fibrous pulp addition, can solve the problems of mesh blockage in the wire part of the paper machine, difficulty in achieving retention and filtering effects, and difficulty in dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

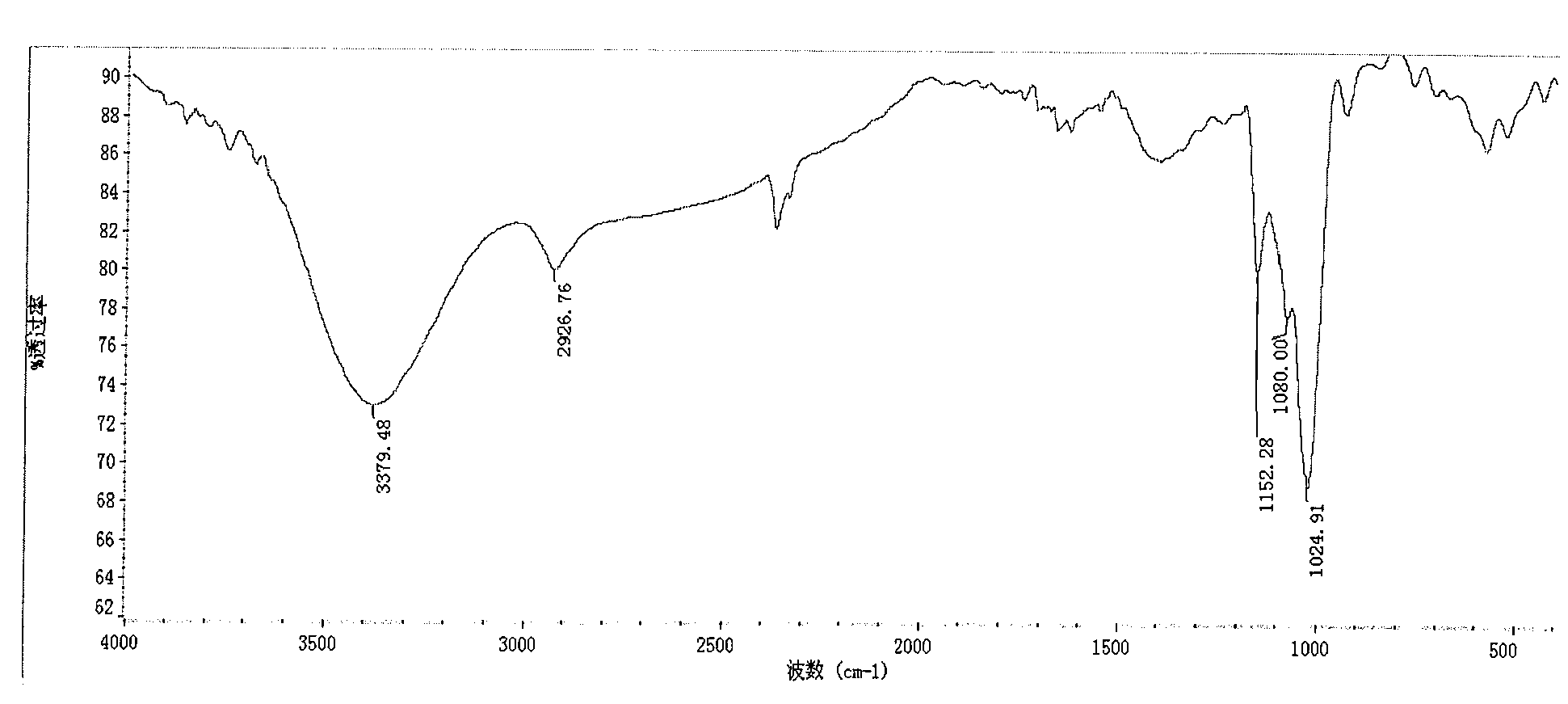

Embodiment 1

[0041] Place 126 g of acrylamide, 118 g of acrylic acid, 8 g of starch, 0.16 g of disodium edetate, 0.017 g of urea, 0.03 g of ammonium persulfate, and 150 deionized water in a beaker. Stir to completely dissolve all materials, slowly add 160 g of 40 wt.% sodium hydroxide solution, and continue to add 40 wt.% sodium hydroxide dropwise until the system pH=7.0, and configure it as an aqueous phase for use. In a four-necked flask (the four-necked flask is equipped with a stirring blade, a thermometer, and a nitrogen inlet and outlet respectively), 28.7g sorbitan glycerate (referred to as Span 80) and 3.3g sorbitan monostearate polyoxyethylene ether (Tween 60 for short) was added to 208g 5# white mineral oil and stirred to completely dissolve it. Under stirring conditions, the water phase was added dropwise to the oil phase. After the addition, the stirring and emulsification were continued for 30 minutes, and then the homogenizer was used for emulsification for 5 minutes to obtain...

Embodiment 2

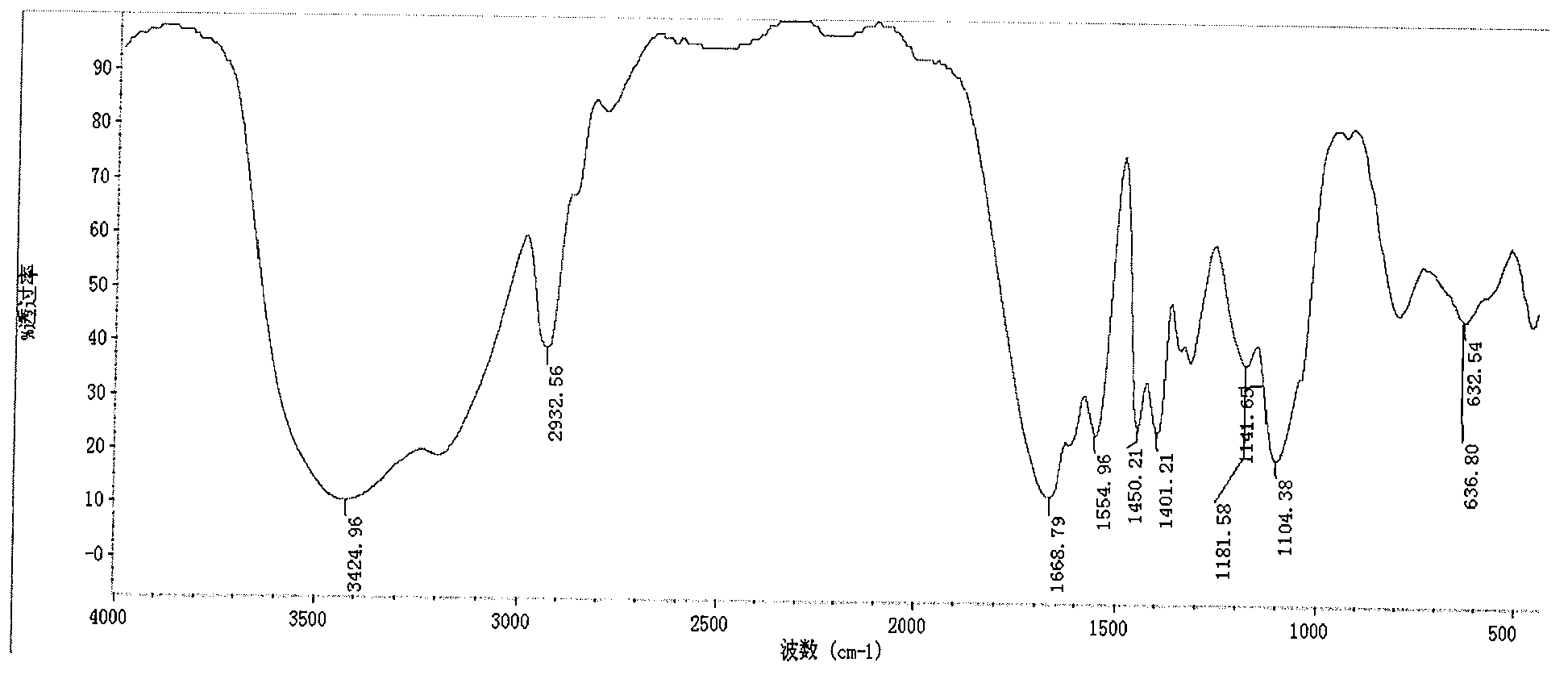

[0045] The preparation process and material ratio are the same as in Example 1, but the amount of starch is adjusted to 4g.

Embodiment 3

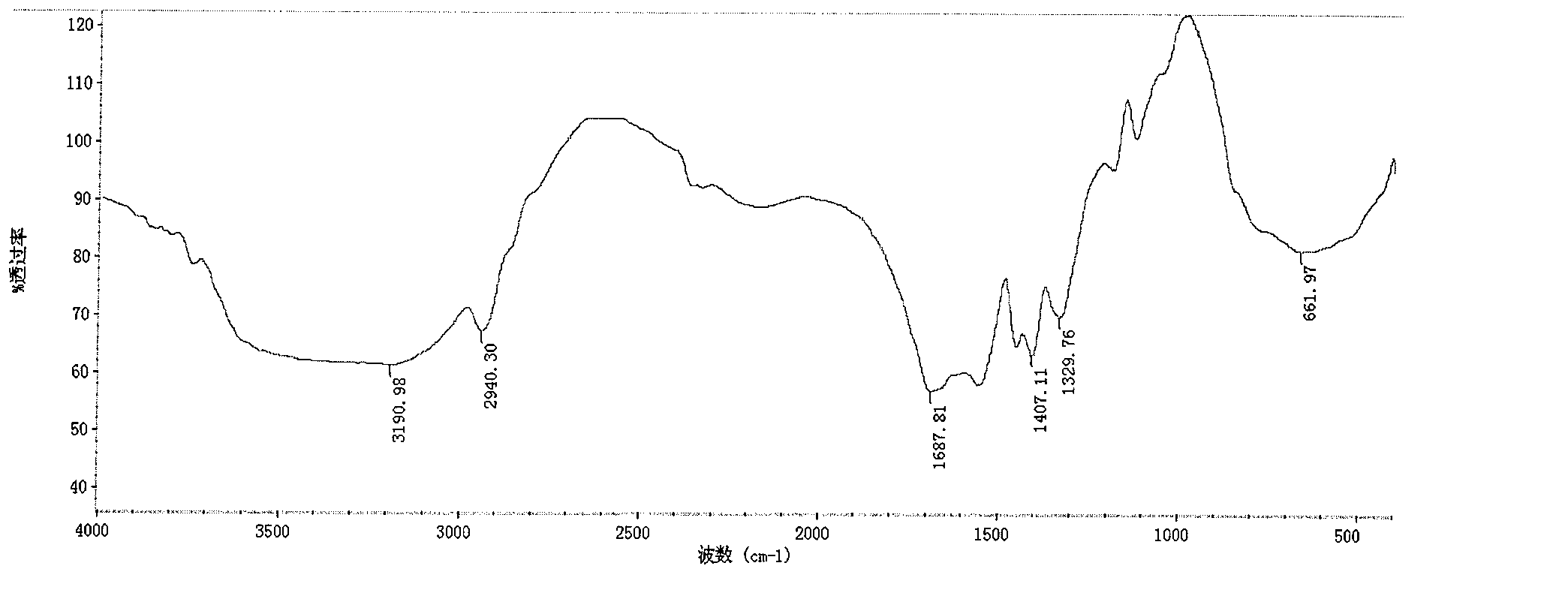

[0047] The preparation process and material ratio are the same as in Example 1, but the amount of starch is adjusted to 0.8g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com