Method for preparing cesium carbonate by ion exchange method

An ion exchange method and cesium carbonate technology, applied in chemical instruments and methods, rubidium/cesium/francium compounds, alkali metal compounds, etc., can solve problems such as complex process, low yield, and reduction of cesium carbonate, and achieve simple process flow , improve the system yield, avoid the effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

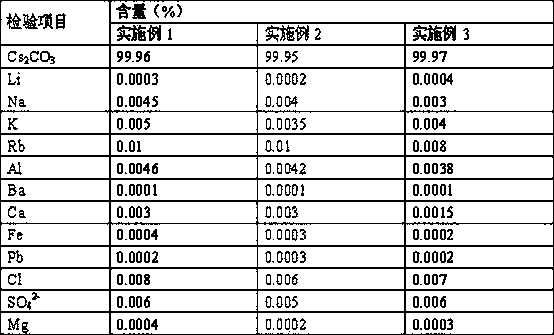

Embodiment 1

[0026] A method for preparing cesium carbonate by ion exchange method, its steps are as follows:

[0027] A. Acid leaching cesium garnet: put 3.5Kg cesium garnet into 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, and the filter is kept above 90°C to obtain acid leaching liquid;

[0028] B, the pickling liquid is cooled to room temperature heavy alum, centrifugal separation gets thick alum 3Kg, discharges after separating mother liquor neutralization treatment, adds pure water in the separated thick alum and carries out twice recrystallization, the liquid-solid mass ratio of each recrystallization The ratio is 8:1, adding pure water to dissolve each time, then heating, evaporating and concentrating to one-third of the original volume, then cooling to room temperature to crystallize to obtain 2.7Kg of refined cesium alum, and the recrystallization mother liquor participates in the circulatio...

Embodiment 2

[0036] A method for preparing cesium carbonate by ion exchange method, its steps are as follows:

[0037] A. Acid leaching cesium garnet: put 35Kg cesium garnet into 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, keep above 90°C and filter to obtain the acid leaching solution ;

[0038] B, the pickling liquid is cooled to room temperature heavy alum, centrifugal separation obtains 31Kg rough alum, discharges after separating mother liquor neutralization treatment, adds pure water in the separated thick alum and carries out twice recrystallization, the liquid-solid mass ratio of each recrystallization The ratio is 8:1, adding pure water to dissolve each time, then heating, evaporating and concentrating to one-third of the original volume, then cooling to room temperature to crystallize to obtain 27.12Kg of refined cesium alum, and the recrystallization mother liquor participates in circu...

Embodiment 3

[0045] A method for preparing cesium carbonate by ion exchange method, its steps are as follows:

[0046] A. Acid leaching cesium garnet: put 220Kg cesium garnet into a reaction kettle with 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, and the filter is kept above 90°C , to get pickling solution;

[0047] B, the pickling solution is cooled to room temperature to sink alum, centrifuged to get rough alum 200Kg, discharge after separation of mother liquor neutralization treatment, add pure water to carry out twice recrystallization in the rough alum of separation, the liquid-solid mass ratio of each recrystallization The ratio is 8:1, adding pure water to dissolve each time, heating, evaporating and concentrating to one-third of the original volume, then cooling to room temperature to crystallize to obtain 180Kg of refined cesium alum, and the recrystallization mother liquor participates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com