Mesoporous nanometer material and method for recycling diosgenin from waste liquor by same

A technology of nanomaterials and turmeric saponin, which is applied in nanotechnology, nanotechnology, separation methods, etc., can solve the problems of cumbersome biochemical combination treatment methods, and achieve the effect of not being prone to secondary pollution, rapid adsorption process, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

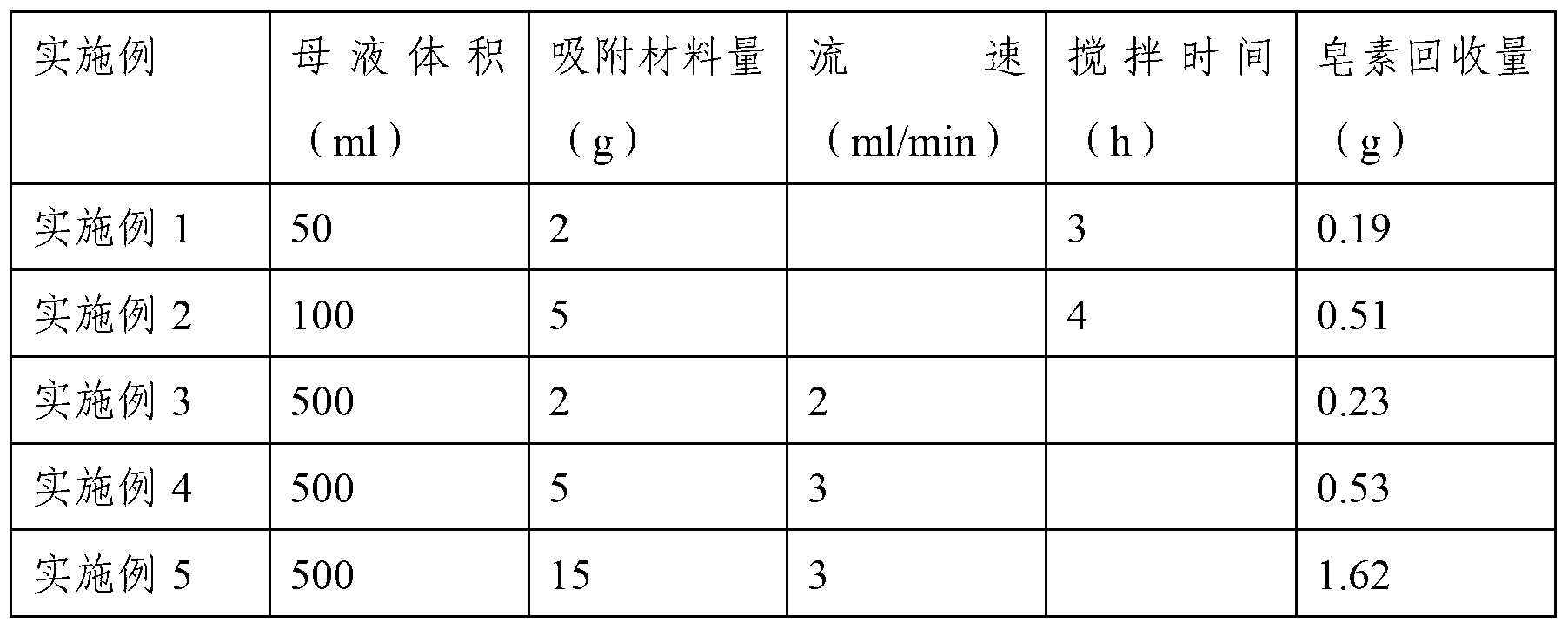

Embodiment 1

[0030] 1) Material synthesis: Disperse 1g of triblock copolymer P123 in a mixed solution of 4mL of 1.0mol / L KCl and 35mL of 0.2mol / L HCl, let it stand at 40°C for 24h, and after aging at 100°C for 24h, wash and filter to synthesize PMO Mesoporous Nanomaterials. The specific surface area and pore volume of the mesoporous material are calculated by Brunauer-Emmett-Teller (BET), the pore diameter is 5-10nm, and the specific surface area is 1100m / g.

[0031] 2) Modification: Take 100mg of PMO mesoporous nanomaterials and 1mL of C 8 Silane was heated to reflux in 100mL toluene solvent for 24 hours to modify the mesoporous silicon nanomaterials.

[0032] 3) Static adsorption: Add 2 g of the modified PMO mesoporous silicon nanomaterials to 50 mL of waste liquid containing 2% turmeric saponin, and keep stirring for 3 h until the saponin in the solution is completely absorbed. The solid-liquid two-phase is separated by filtration to obtain the solid-phase material adsorbed with sapon...

Embodiment 2

[0035] 1) Material synthesis: Disperse 2g of triblock copolymer P123 in a mixed solution of 5mL of 1.0mol / L KCl and 40mL of 0.2mol / L HCl, let it stand at 40°C for 24h, and after aging at 100°C for 24h, wash and filter to synthesize PMO Mesoporous Nanomaterials. The mesopore diameter is 5-10nm and the specific surface area is 1120m / g as measured by BET method.

[0036] 2) Modification: Take 200mg of PMO mesoporous nanomaterials and 2mL of C 8 The silane was heated to reflux in 200ml of toluene solvent for 24 hours to modify the mesoporous silicon nanomaterial.

[0037] 3) Static adsorption: Add 5 g of modified PMO mesoporous silicon nanomaterials to 100 mL of waste liquid containing 2% turmeric saponin, and keep shaking for 4 hours. The solid-liquid two-phase is separated by filtration to obtain the solid-phase material adsorbed with saponin, and further eluted to obtain a pure solution containing saponin.

[0038] 4) Elution: The separated solid-phase material is used to el...

Embodiment 3

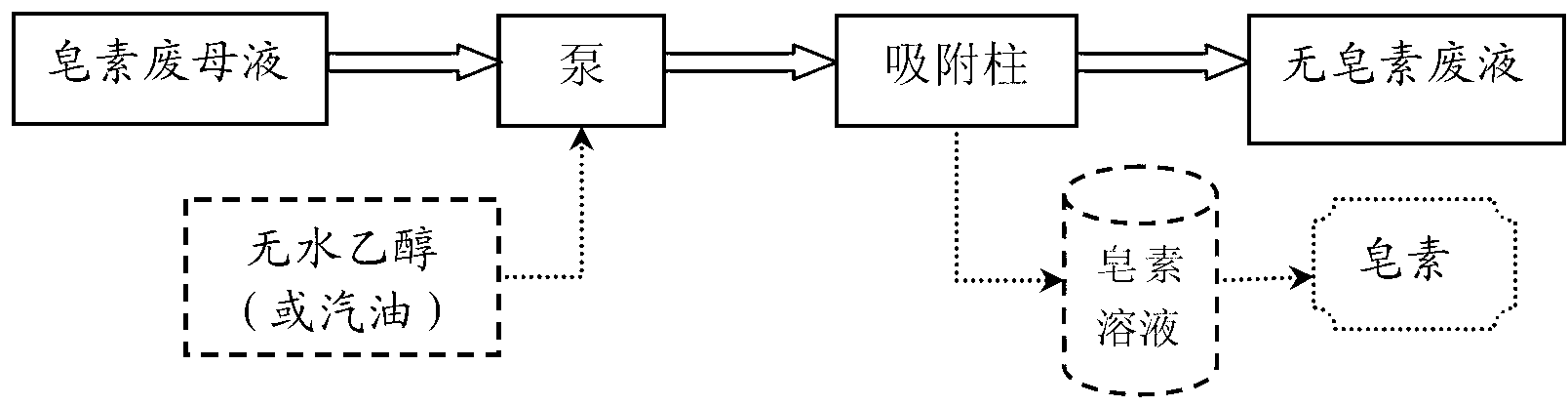

[0040] The adsorbed liquid is waste liquid containing 2wt% turmeric saponin, a total of 500mL. see process figure 1 , steps 1) and 2) are the same as in Example 1.

[0041] 3) Adsorption (elution) column The adsorption (elution) column is made of a glass tube. Glass fibers are placed at both ends of the column to prevent the material from seeping out. The column is filled with 2g of modified PMO mesoporous silicon nanoparticles. Drive away the air bubbles between the solid particles, and use a peristaltic pump to control the flow rate to 2mL / min, so that the turmeric saponin contained in the solution is completely absorbed by the PMO mesoporous silicon nanomaterial.

[0042] 4) Elution: After the adsorption is completed, the saponin is eluted with gasoline of the same volume as the waste liquid, and the obtained solution is the eluent containing saponin. After concentration, crystallization and purification, pure saponin is obtained. After the elution is complete, the PMO me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com