Semiconductor porous bismuth oxide nanosphere and preparation method and application thereof

A semiconductor and nanosphere technology, applied in the field of nanomaterials and photocatalysis, can solve the problems of nanomaterial morphology, less size synthesis route, no spherical nanostructure, and difficulty in liquid phase synthesis, etc., which is conducive to market promotion, excellent The effect of degradation performance and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

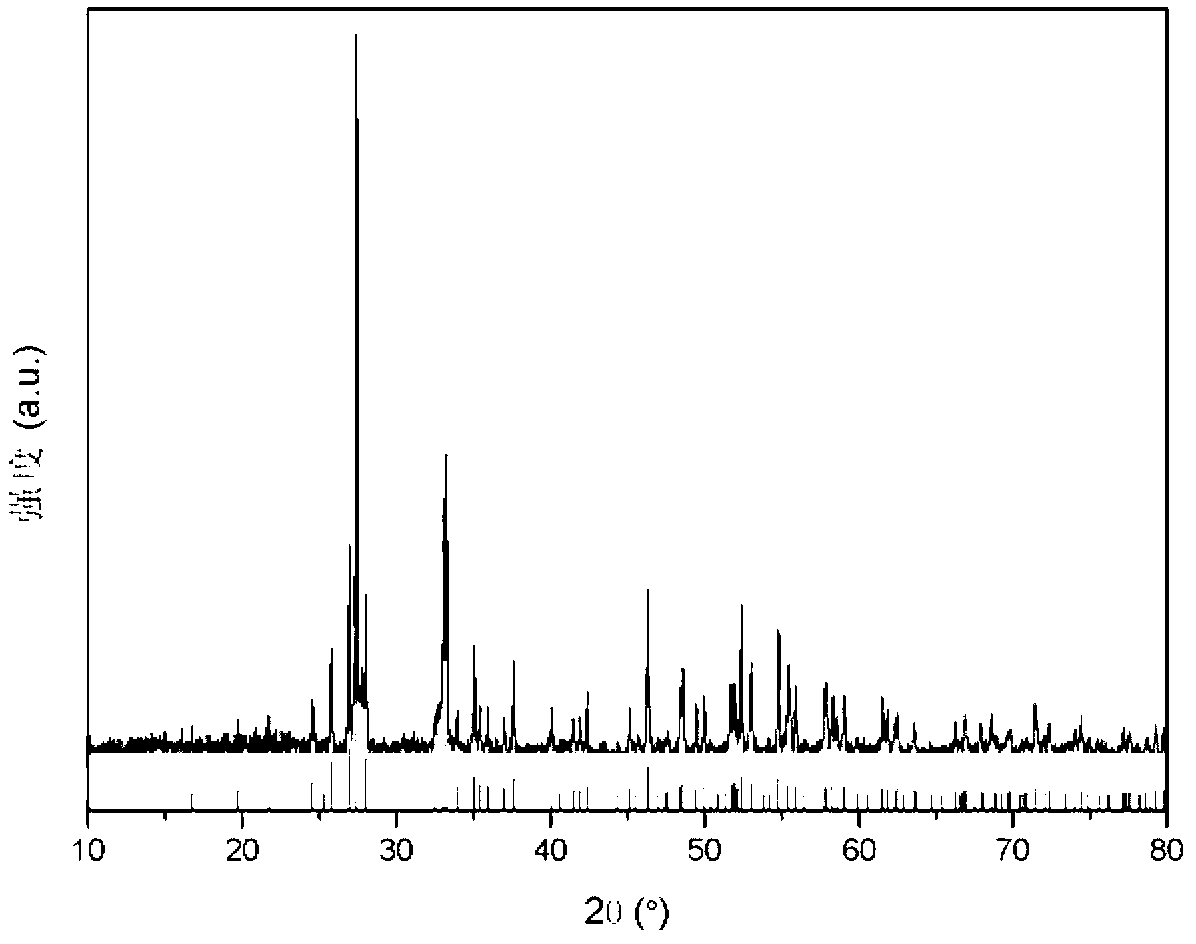

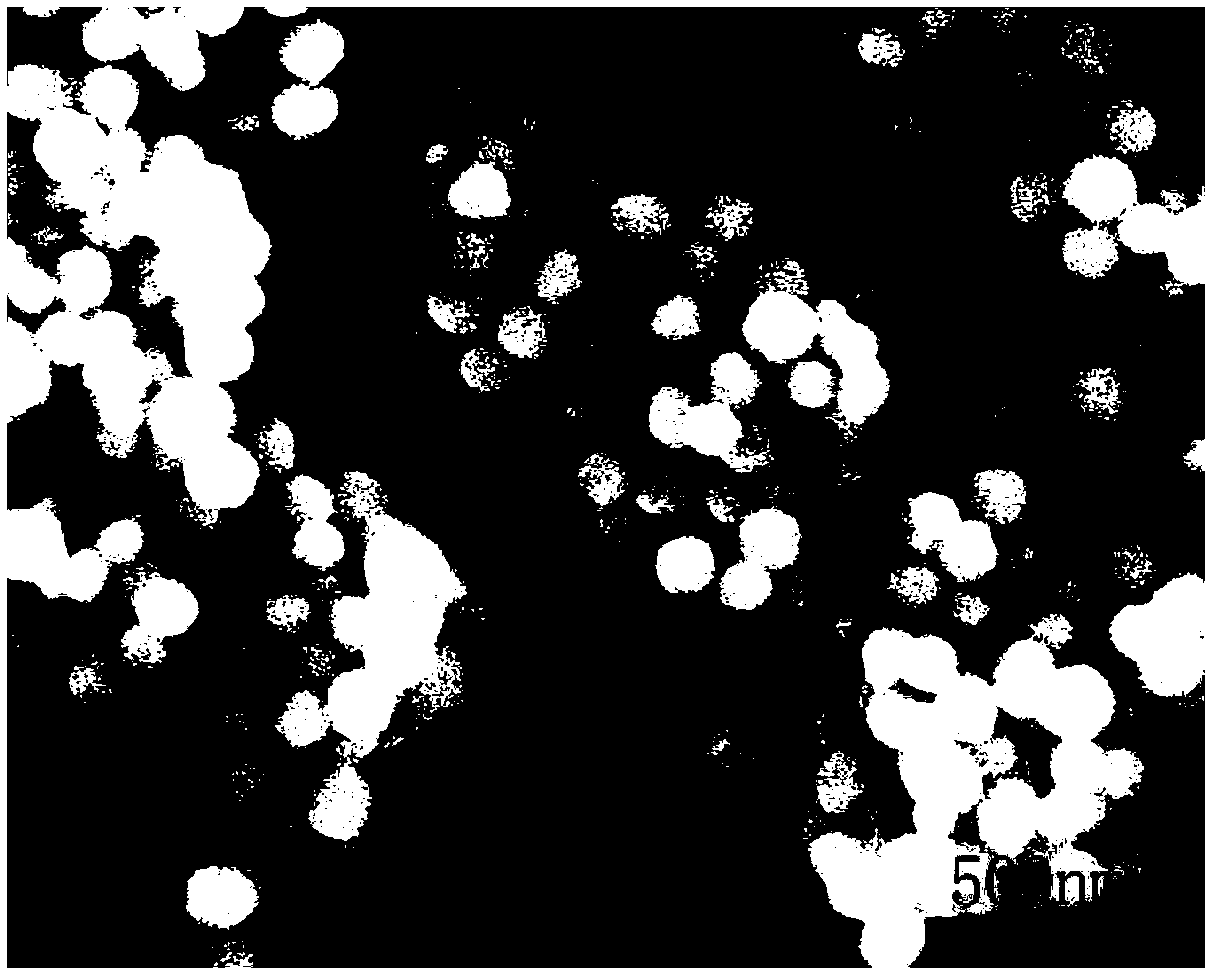

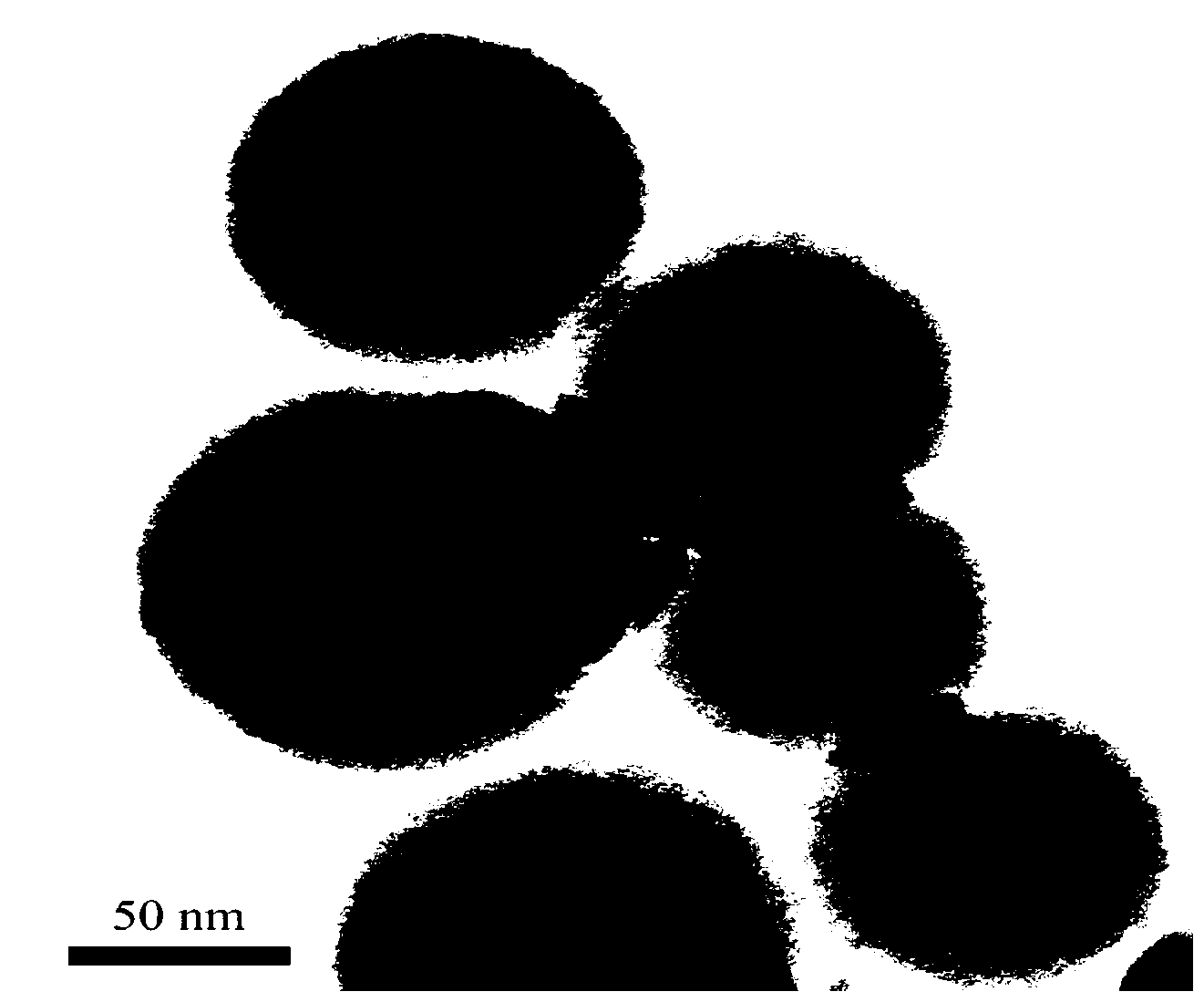

[0033] The preparation of porous bismuth oxide nanospheres of semiconductor photocatalytic materials by soft film plate method comprises the following steps:

[0034] 1) Add 0.076g (1.567*10 -4 mol) bismuth nitrate pentahydrate and 25ml deionized water to make a solution, and 0.21g (4.88*10 -4 mol) sodium cholate and 10ml deionized water to make a solution, mix and stir the two solutions evenly to obtain a 35ml solution;

[0035] 2) Add 1ml of hydrogen peroxide to the above mixed solution, transfer the obtained mixed solution into a reaction kettle, and react at 200°C for 8 hours to obtain a khaki precursor solution;

[0036] 3) Cool the obtained precursor solution naturally, wash it, and place it in an oven at 60°C until it is completely dried;

[0037] 4) Grind the precursor obtained after drying evenly, put it into a tube furnace, and calcinate it at 500°C for 2 hours in an air atmosphere to obtain a yellow powder that is bismuth oxide nanospheres.

[0038] Taking bismut...

Embodiment 2

[0044] The preparation of porous bismuth oxide nanospheres of semiconductor photocatalytic materials by soft film plate method comprises the following steps:

[0045] 1) Make a solution of 0.06g of bismuth nitrate pentahydrate and 15ml of deionized water, and make a solution of 0.21g of sodium cholate and 10ml of deionized water, mix and stir the two solutions to obtain a 25ml solution;

[0046] 2) Add 0.5ml hydrogen peroxide to the above mixed solution, transfer the obtained mixed solution into a reaction kettle, and react at 200°C for 8 hours to obtain a khaki precursor solution;

[0047]3) Cool the obtained precursor solution naturally, wash it, and place it in an oven at 60°C until it is completely dried;

[0048] 4) Grind the precursor obtained after drying evenly, put it into a tube furnace, and calcinate it at 500°C for 2 hours in an air atmosphere to obtain a yellow powder that is bismuth oxide nanospheres.

[0049] The bismuth oxide nanosphere material prepared by th...

Embodiment 3

[0051] The preparation of porous bismuth oxide nanospheres of semiconductor photocatalytic materials by soft film plate method comprises the following steps:

[0052] 1) Make a solution of 0.076g of bismuth nitrate pentahydrate and 25ml of deionized water, and make a solution of 0.202g of sodium cholate and 5ml of deionized water, mix and stir the two solutions to obtain a 30ml solution;

[0053] 2) Add 1.5ml of hydrogen peroxide to the above mixed solution, transfer the obtained mixed solution into a reaction kettle, and react at 200°C for 9 hours to obtain a khaki precursor solution;

[0054] 3) Cool the obtained precursor solution naturally, wash it, and place it in an oven at 60°C until it is completely dried;

[0055] 4) Grind the precursor obtained after drying evenly, put it into a tube furnace, and calcinate it at 500°C for 2 hours in an air atmosphere to obtain a yellow powder that is bismuth oxide nanospheres.

[0056] The bismuth oxide nanosphere material prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com