Ultrahigh cross-linked resin SX-01 and application thereof

An ultra-high cross-linking resin and resin technology, applied in the biological field, can solve the problems of high consumption, pollution, and many unit operations, and achieve the effect of reducing dosage, reducing environmental pollution, and good adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the acquisition of UMP feed liquid

[0036]RNA enzymatic hydrolysis process, using nuclease solution to act on RNA solution to obtain 4 kinds of 5'-mononucleotides, namely 5'-adenylic acid (AMP), 5'-cytidylic acid (CMP), 5'- Guanylate (GMP) and 5'-Uridylic acid (UMP). Specific steps are as follows:

[0037] (1) Prepare 600mL of 6% RNA solution with pH=5.5. First adjust the pH to 12 with NaOH, then add RNA (36g) to dissolve, then adjust the pH to 5.5 with NaOH, and place in a 70°C water bath to preheat to 70°C.

[0038] (2) Add 50 mL of enzyme solution preheated for half an hour to the RNA solution, shake well, control the reaction temperature at 70°C, and perform enzymatic hydrolysis for 185 minutes.

[0039] (3) Add 0.2% (1.2g) activated carbon and continue enzymatic hydrolysis for 50 minutes.

[0040] (4) Finally, cool to 45°C for enzymatic hydrolysis, centrifuge (400rpm, 10min), and filter to obtain RNA enzymatic hydrolysis solution.

[0041] Pass ...

Embodiment 2

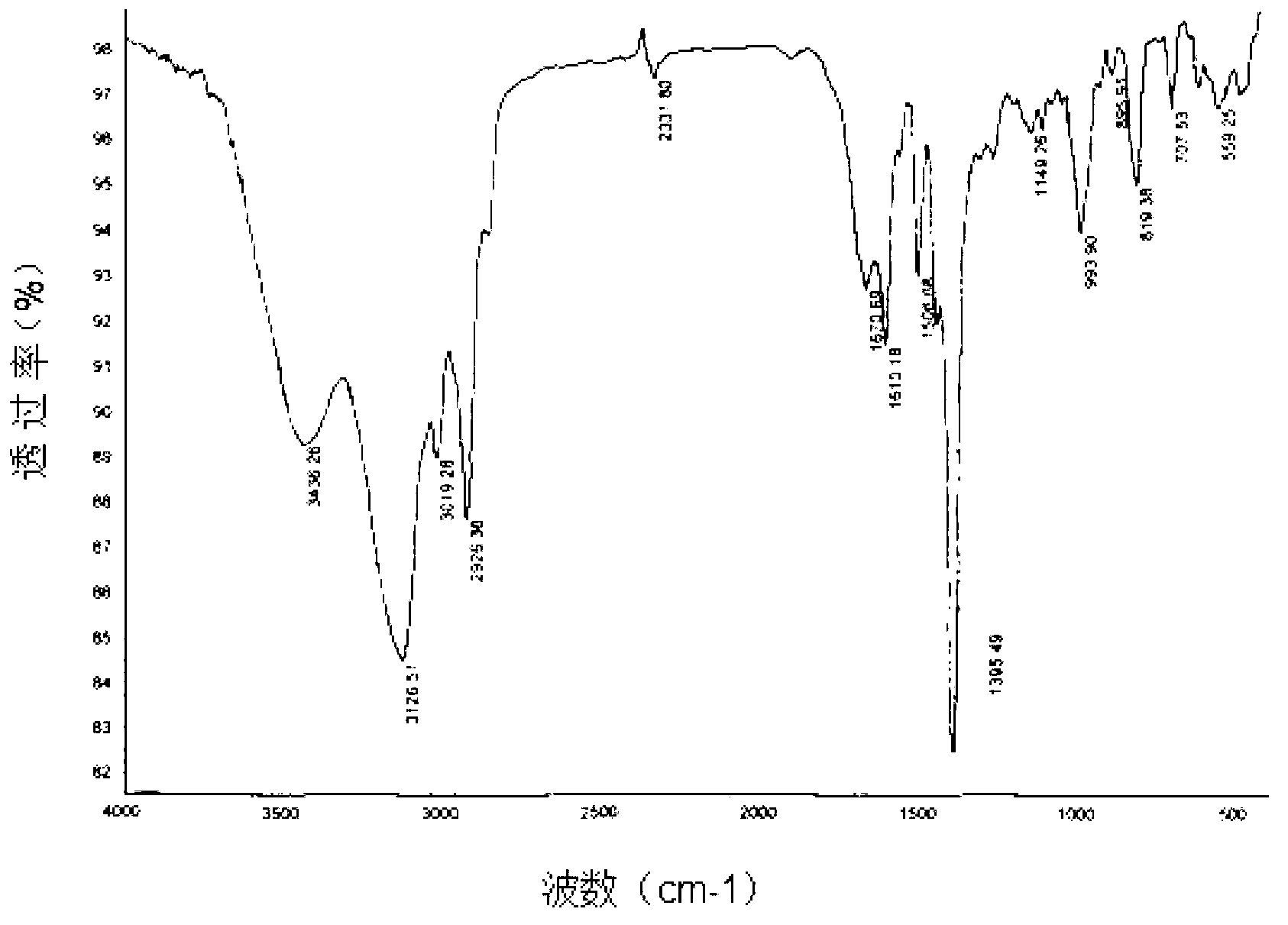

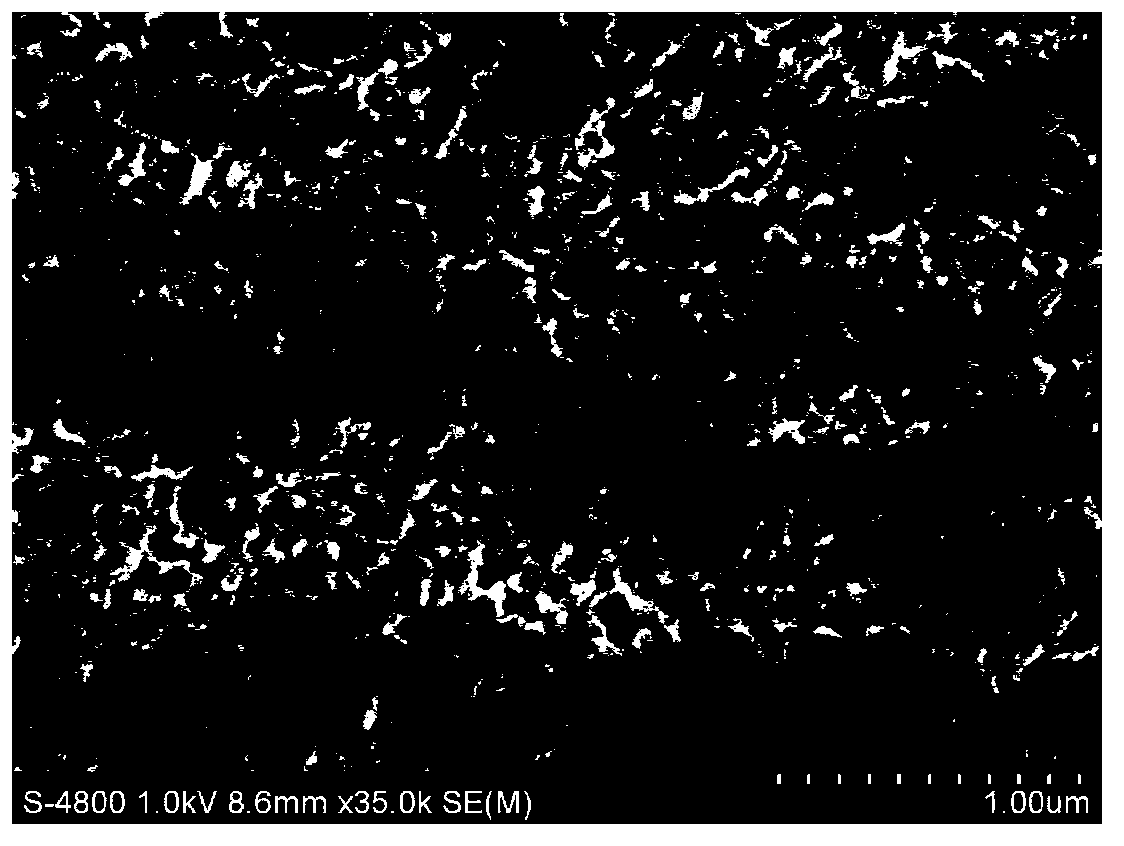

[0042] Embodiment 2: the acquisition of super high cross-linked resin SX-01

[0043] In a clean and dry 2000mL three-neck flask, add 200g of dry chloromethylated polystyrene resin (chlorine balls), add 1200g of o-nitroethylbenzene, stir and mix well, fully swell at room temperature for more than 2 hours, stir and add Methylamine 4 times the weight of chlorine balls, then add 20g of anhydrous ferric chloride as a catalyst, program temperature rise to 135-150°C under stirring, and then carry out Friedel-Crafts post-crosslinking reaction at this temperature for a certain period of time to control the residual chlorine content At 1-3%, stop the reaction, suck out the mother liquor after cooling, and repeatedly extract the resin with industrial alcohol until the extraction effluent is colorless and clear, then wash the resin with 4% hydrochloric acid and distilled water until it is neutral, and dry it for later use.

[0044] The obtained product is in the shape of brown round parti...

Embodiment 3

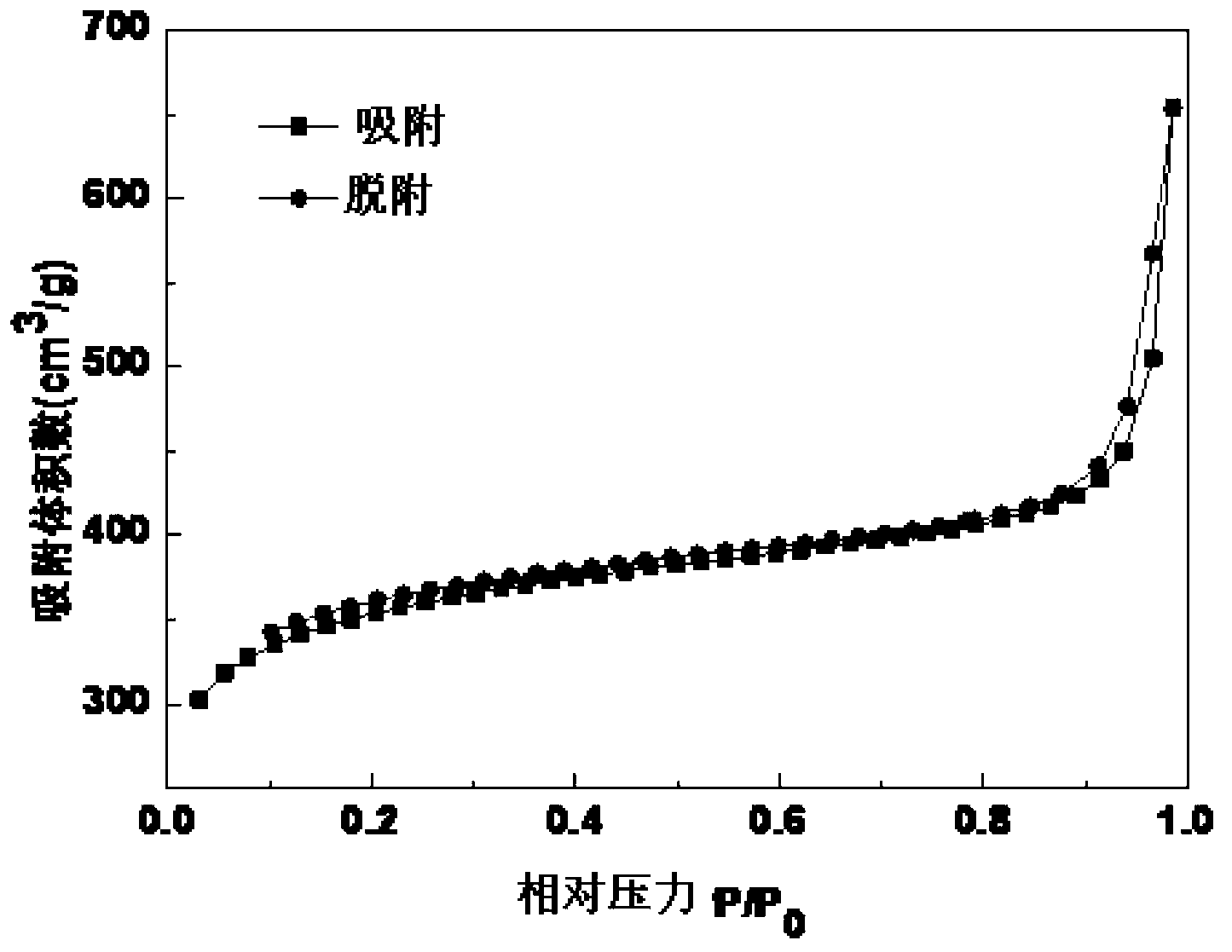

[0045] Embodiment 3: the drawing of the adsorption isotherm of ultra-high crosslinking resin SX-01

[0046] Figure 5 The adsorption isotherm of UMP is simulated by Langmuir. The experimental process is: prepare UMP solutions with different concentrations of pH=1.6, pipette 50mL into 100mL Erlenmeyer flasks, and add 5g of ultra-high crosslinking resin SX-01 respectively. After sealing, place them in constant temperature shakers at 293K, 313K, and 333K respectively, set the rotation speed at 160rpm, and measure the concentration of UMP in the solution after adsorption equilibrium. The experimental data were fitted using the Langmuir isotherm equation.

[0047] The result is as Figure 5 It can be seen that the adsorption process of UMP conforms to the Langmuir adsorption isotherm model. With the increase of temperature, the adsorption capacity of ultra-high cross-linked resin SX-01 to UMP decreased, indicating that the adsorption process of the resin to UMP may be an exother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com