Novel system for transferring biocatalytic reaction substrate based on high-molecular material

A polymer material and biocatalysis technology, which is applied in the field of new biocatalysis reaction substrate delivery system based on polymer materials, can solve the problem of no general and convenient selection method, negative enzyme activity and stability, and difficulty in obtaining the most suitable System and other issues, to achieve the effect of controllable release, increase the concentration of reaction substrate, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of 2-oxo-4-phenylbutyric acid sodium salt. Weigh 20g of 2-oxo-4-phenylbutyric acid, stir and dissolve in 200ml ethanol; weigh 4.5g NaOH, stir and dissolve in 250ml ethanol to prepare NaOH ethanol solution. Pour the ethanol solution of NaOH into the ethanol solution of 2-oxo-4-phenylbutyric acid, stir for 1 hour to fully react, and stand at 4°C overnight. The precipitate was collected by suction filtration, washed with 1 L of ethanol at 4°C, and evaporated to dryness at room temperature. The precipitate obtained by HPLC analysis is indeed 2-oxo-4-phenylbutyric acid sodium salt with a purity greater than 97%.

[0049] The conversion rate and product purity of 2-oxo-4-phenylbutyric acid and its sodium salt and L-homophenylalanine were carried out by reverse phase C18 column (Waters Symmetry, 150mm×4.6mm, 5mm) for HPLC (Shimadzu2010A HT, Japan) analysis, the mobile phase is: A pump water (containing 0.1% trifluoroacetic acid), B pump acetonitrile (containing 0...

Embodiment 2

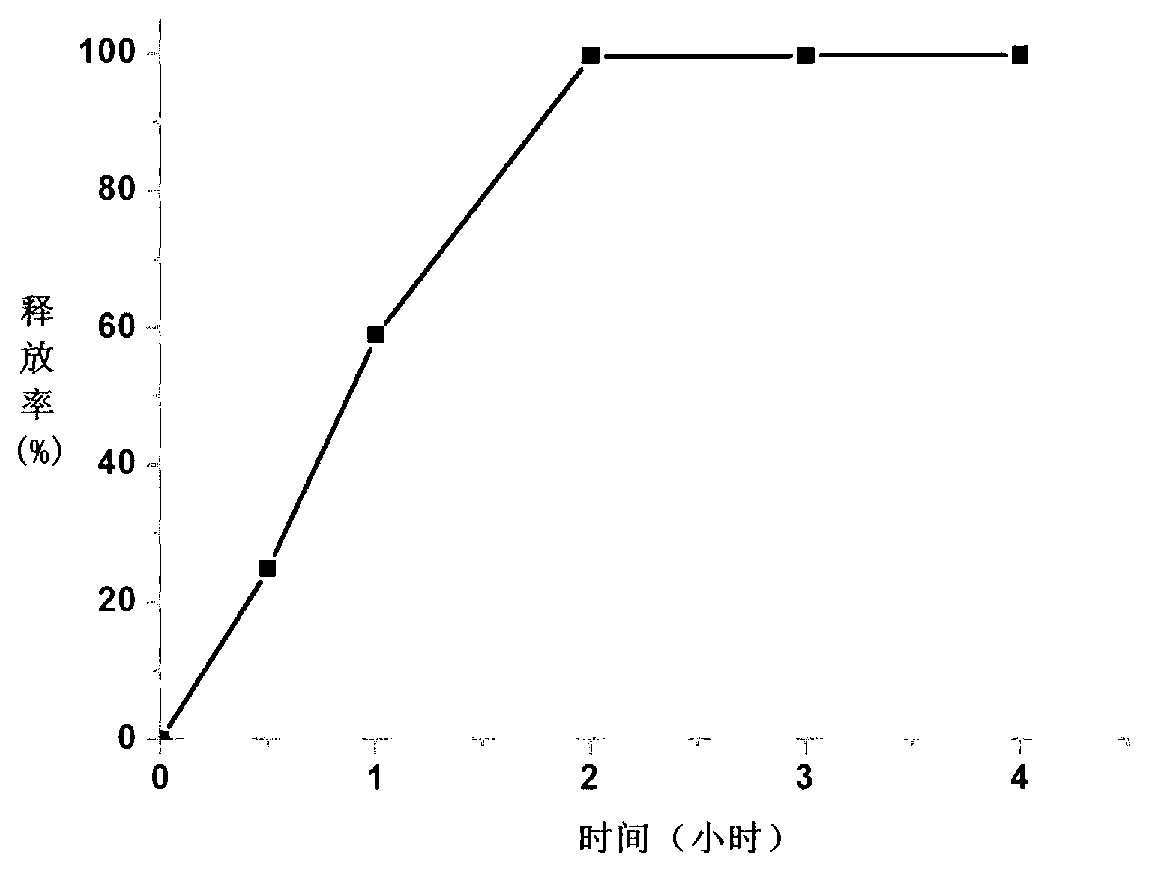

[0051] Calcium alginate substrate delivery system preparation. Weigh a certain amount of sodium alginate, stir and dissolve it in 6ml of water to prepare a sodium alginate solution with a concentration of 0.5-4% (w / w). Add the substrate 2-oxo-4-phenylbutyric acid or its sodium salt to the sodium alginate solution according to the polymer / substrate ratio of 1-2:1, and stir for 1 hour to dissolve or disperse evenly. The resulting solution was continuously added dropwise to 0.05M ~ 0.4M CaCl under stirring 2 In aqueous solution, sodium alginate solution and CaCl 2 The volume ratio of the solution was 1:1-1:10, and the cross-linking was promoted by continuous stirring for 0.5-10 hours. It was found that calcium alginate pellets could be formed after stirring for more than 1 hour. The obtained calcium alginate pellets were collected by suction filtration, washed three times with water, and dried at 60° C. for 12 to 24 hours to obtain substrate-loaded calcium alginate pellets.

...

Embodiment 3

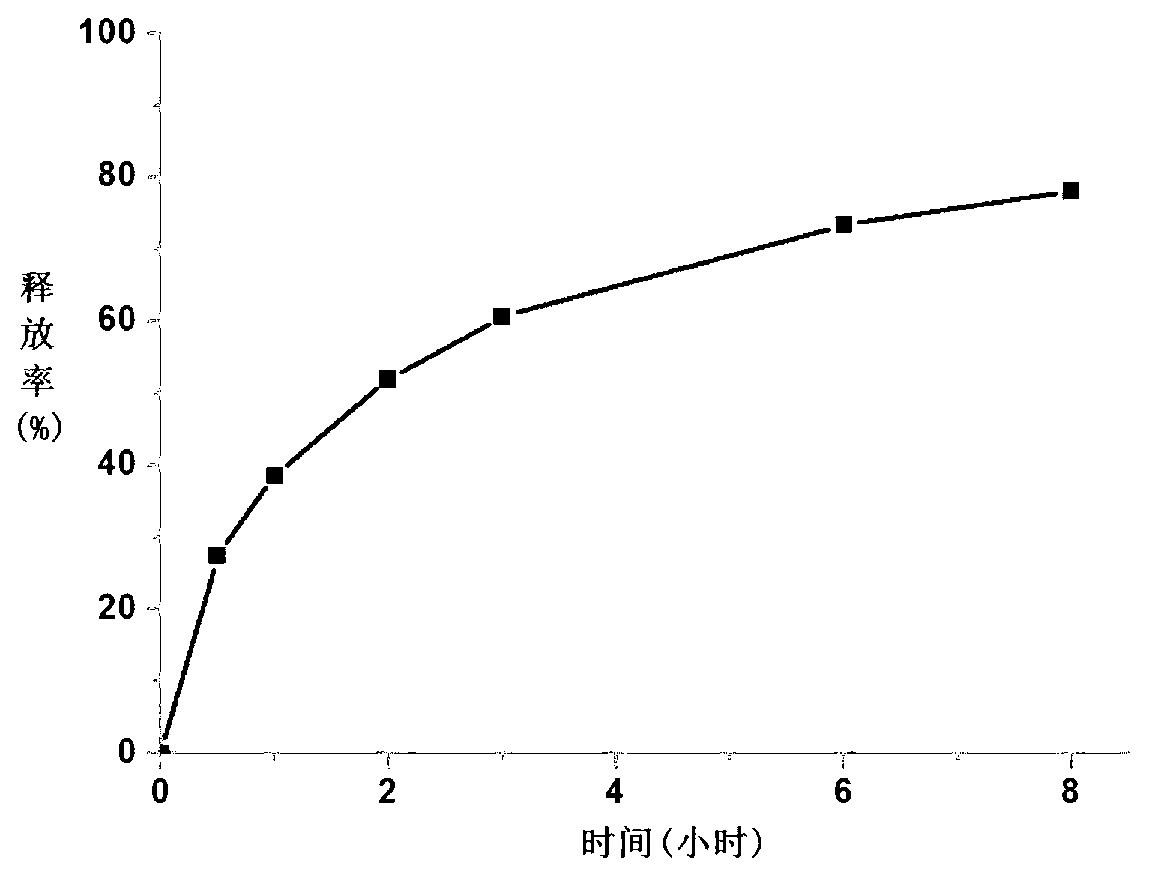

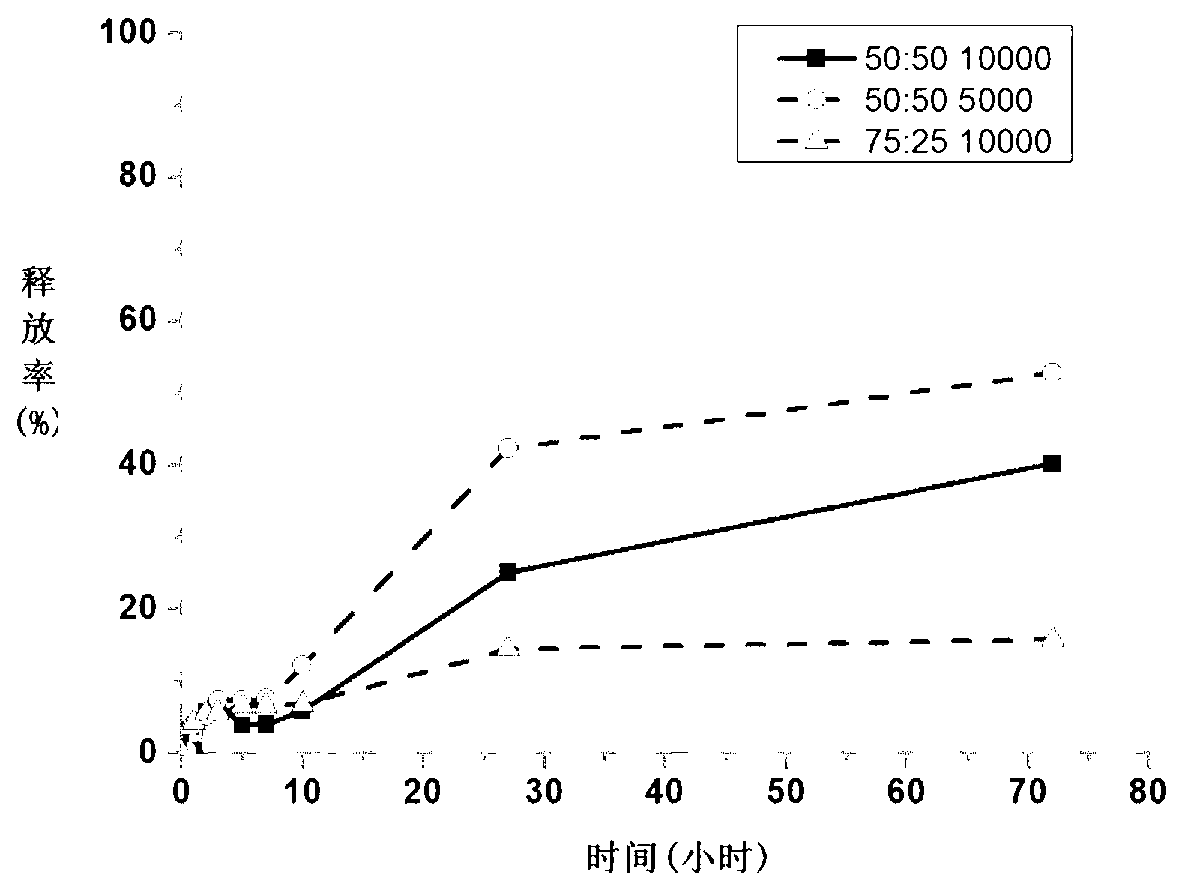

[0054] Ethylcellulose substrate delivery system preparation. Weigh a certain amount of ethyl cellulose, prepare 5ml of 6% acetone solution, add the substrate 2-oxo-4-phenylbutyric acid or its sodium salt according to the ethyl cellulose / substrate ratio of 90:1~1:3 , Ultrasonic stirring for 2h to dissolve or disperse evenly, as the internal oil phase. Add the inner oil phase drop by drop into the outer oil phase composed of liquid paraffin containing 2-5% Span 80 under stirring, the ratio of the inner oil to the outer oil phase is 1:10, and the rotation speed is 100-600rpm. Continue stirring for 3h to volatilize acetone and form particles. When collecting particles, add n-hexane equal to the volume of the outer oil, let it stand, and pour off the upper liquid, filter to collect the particles, and wash with one of n-hexane, petroleum ether or n-heptane twice the volume of the outer oil phase, Evaporate the organic solvent at room temperature to obtain microparticles prepared f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com