Preparation method of modified PLGA-PEG nano-fiber blanket

A nanofiber, modification technology, applied in the field of preparation of modified PLGA-PEG nanofiber mat, to achieve the effect of easy product, wide application prospect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

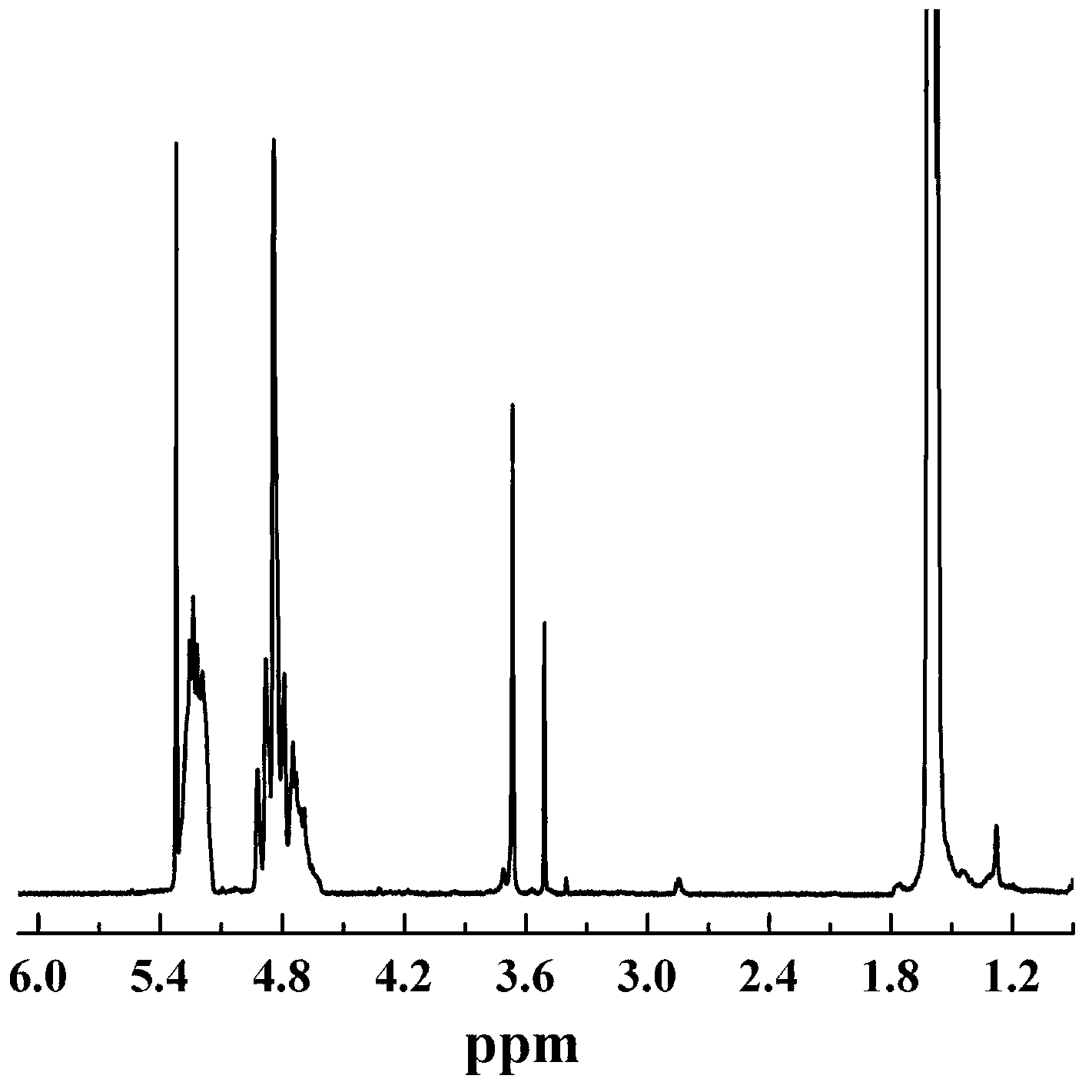

[0045] Take 1.5g of PLGA, mix it with 6ml of chloroform, and stir at room temperature for 6h until PLGA is completely dissolved. Then add 45mg of EDC to activate the carboxyl group at the end of PLGA, the activation time is 3-4 hours, then add 230mg of mPEG-NH 2 , stirred at room temperature for 3 days. The reaction solution was slowly added dropwise into iced methanol, the unreacted mPEG-NH 2 Soluble in methanol, PLGA-PEG precipitates. The solid was taken out and washed three times with ice methanol again. The obtained product was dried in a vacuum oven for 3 days. Take out 5mg of PLGA-PEG, dissolve it with deuterated chloroform and transfer it to an NMR tube. The product is evaluated by nuclear magnetic resonance (NMR), and the NMR test results (see attached figure 1 ) showed that the three characteristic peaks of PLGA appeared at 1.6ppm, 4.8ppm and 5.2ppm respectively; while the characteristic peaks of PEG appeared at 3.7ppm. Therefore, it can be confirmed that the ob...

Embodiment 2

[0047] Weigh 0.5g of PLGA and PLGA-PEG into a vial, add 1.5ml of THF and 0.5ml of DMF, stir at room temperature until completely dissolved, add 5mg of AMX to the two vials respectively, and make AMX and PLGA and PLGA -The mass ratio of PEG reaches 1:100, and ultrasonic stirring makes AMX uniformly dispersed, so as to obtain a uniform electrospinning solution.

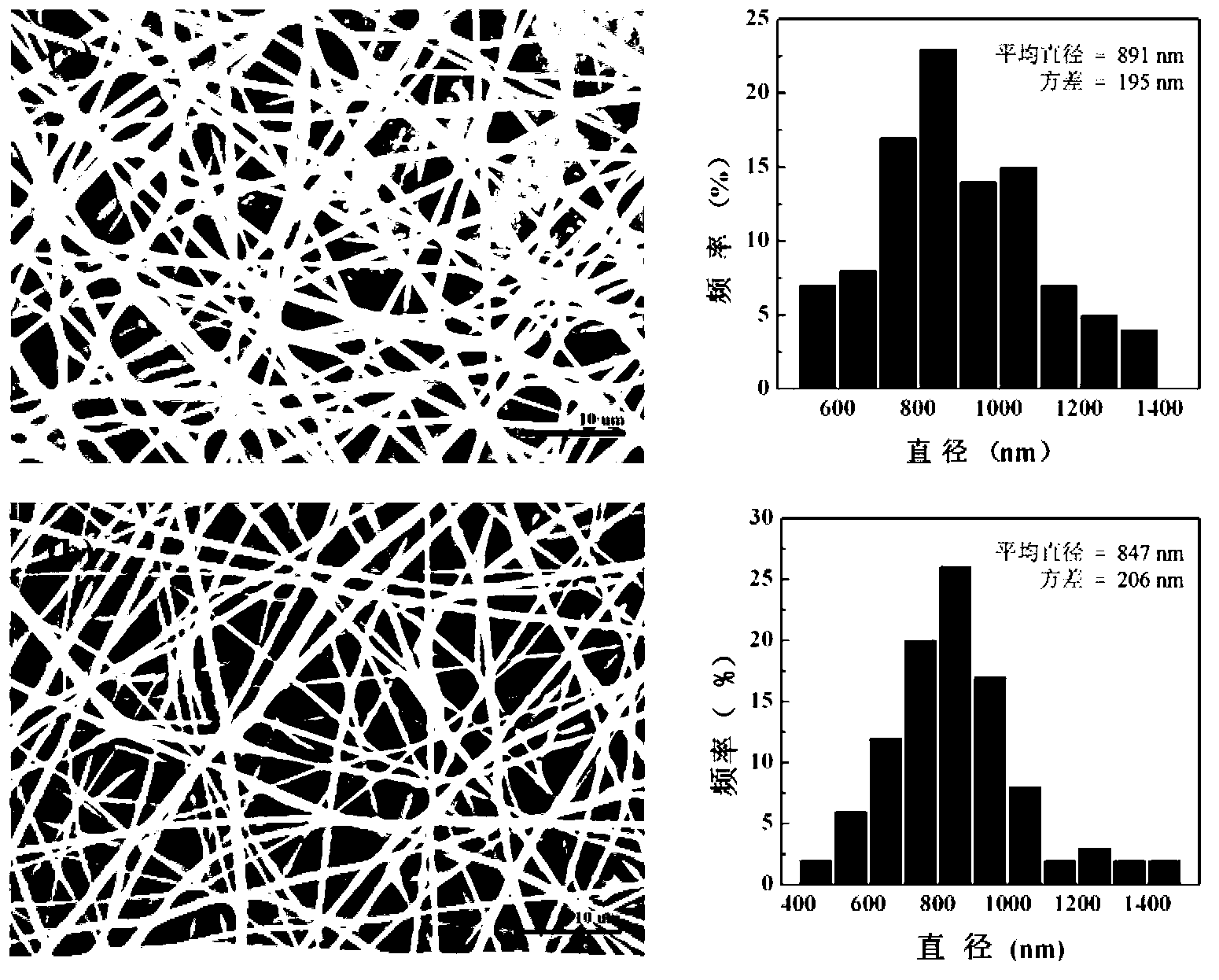

[0048] AMX / PLGA and AMX / PLGA-PEG drug-loaded nanofiber mats were then prepared by conventional electrospinning. Among them, the receiving distance is 15cm, the voltage is 18kV, and the flow rate is 0.8mL / h. The prepared nanofiber mat is dried in a vacuum oven for 48h to remove residual moisture and solvent. SEM observation results show that the obtained AMX / PLGA and AMX / PLGA-PEG nanofibers have regular morphology and regular surface, and the fiber diameters are 891±195nm and 847±206nm respectively (see attached figure 2 ). Comparing the diameters of these two different fibers, it can be found that under the same spin...

Embodiment 3

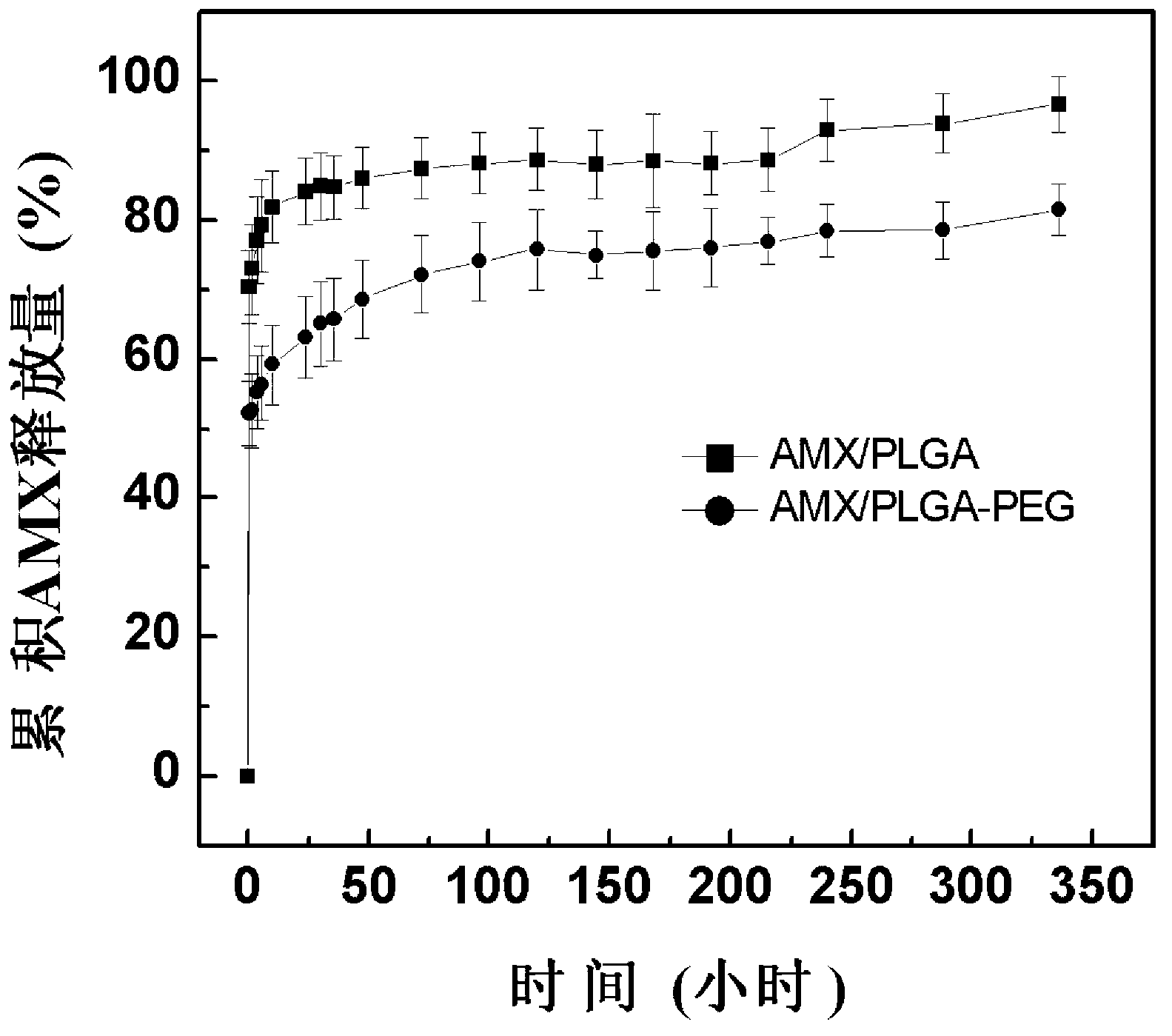

[0050] 100 mg of the electrospun AMX / PLGA and AMX / PLGA-PEG nanofiber mats obtained in Example 2 were respectively placed in a reagent bottle containing 10 mL of PBS buffer for sustained release experiments.

[0051] Place the reagent bottle in a shaker at 37°C and shake it. At different time points, 1.5 mL of the solution is taken out of the reagent bottle, and then supplemented with 1.5 mL of PBS buffer. The concentration of the taken-out sustained-release solution was tested with a UV spectrophotometer, and the concentration-absorbance calibration curve of AMX in PBS was used to calculate the sustained-release percentage at different time points and analyze the drug release kinetics of the PLGA and PLGA-PEG carrier drug-loaded systems. . From attached image 3 It can be seen that compared with the AMX / PLGA nanofiber drug-carrier system, the electrospun AMX / PLGA-PEG nanofiber carrier drug-loaded system can effectively slow down the "burst release" phenomenon of the drug, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com