Graphene oxide-hydrogel composite drug carrier

A graphene composite and hydrogel technology, which is applied in the loading and release of drugs in composite hydrogels, and the composite field of graphene materials and hydrogel materials, can solve the problems of loss of performance and easy agglomeration, and achieve good results. The effect of biocompatibility, good biocompatibility, great social benefit and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation of water-soluble graphene oxide:

[0050] Pre-oxidation process: weigh 0.5gK 2 S 2 o 8 , 0.5gP 2 o 5 , were slowly added to 30mL of concentrated sulfuric acid in turn, and then 1g of natural graphite powder was added to form a mixture solution, stirred and reacted at 80°C for 6h, and cooled to room temperature. Finally, it was washed and centrifuged with deionized water until pH = 7, and dried overnight in an oven at 60°C to obtain the preoxidized product.

[0051] Secondary oxidation process: Measure 23mL of concentrated sulfuric acid in a beaker, place it in an ice-water mixing bath, gradually add pre-oxidized graphite under constant stirring, control the reaction temperature below 10°C, and then slowly add 3gKMnO 4 , stir for a few minutes until the temperature no longer rises. The temperature was raised to 35°C and stirring was continued for 2 h, and 46 mL of deionized water was added. After continuing stirring for 15 min in a water bath at 98°C, ...

Embodiment 1

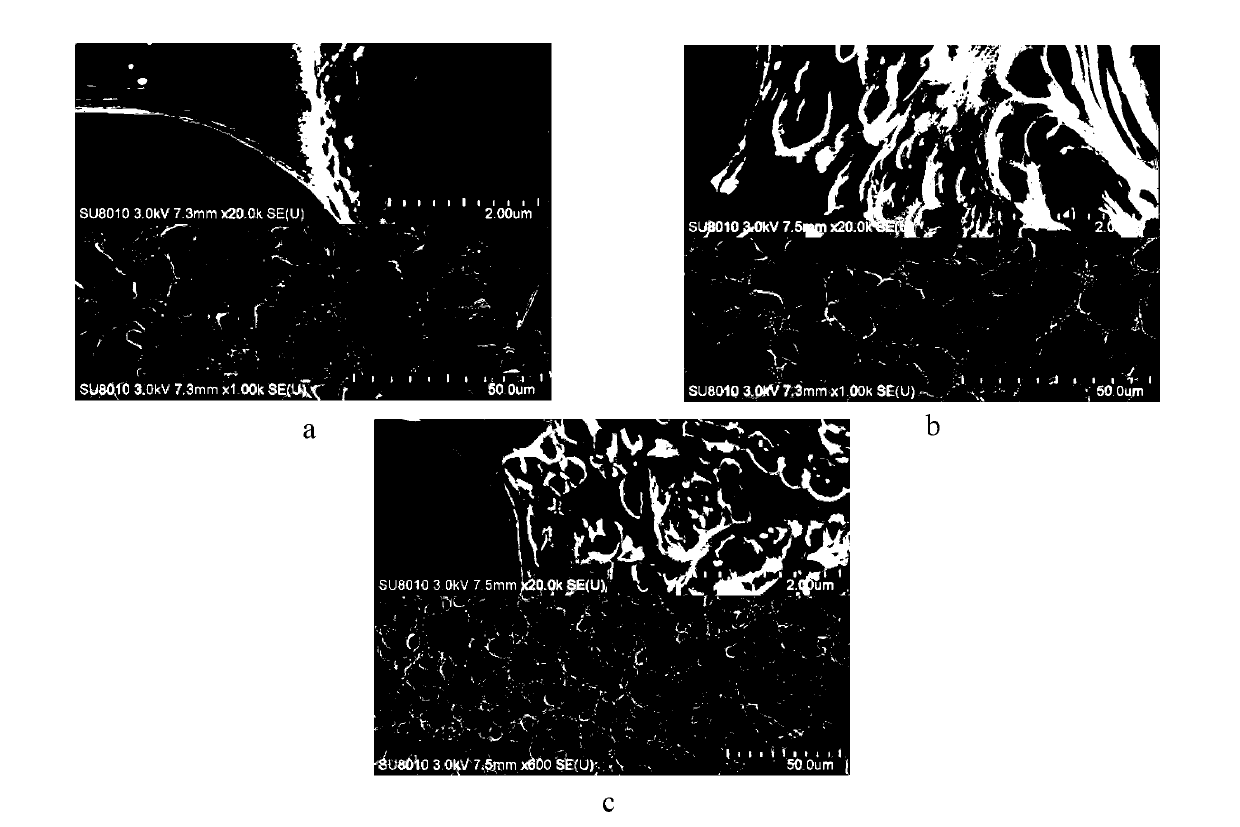

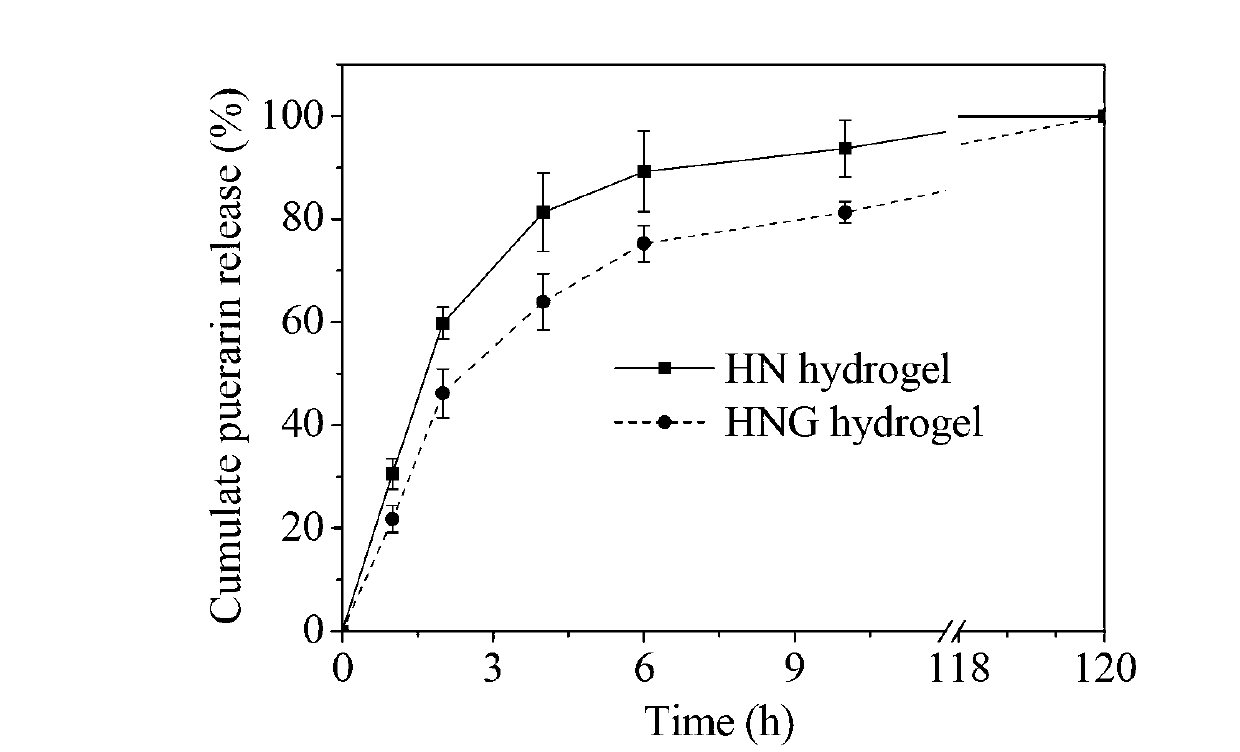

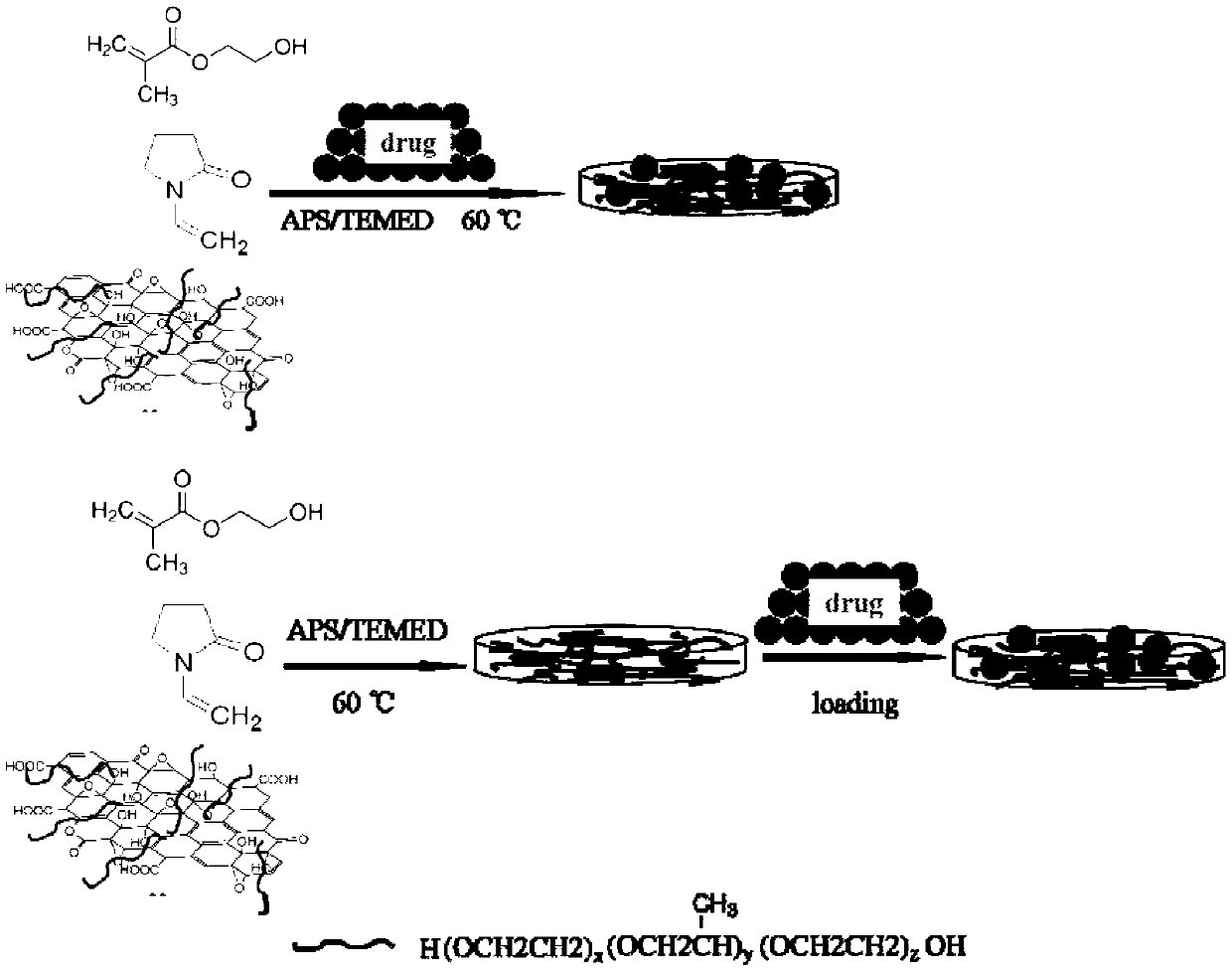

[0054] Add F-127 to the 1 mg / mL graphene oxide aqueous dispersion to make the final F-127 concentration 25 mg / mL, disperse it evenly by magnetic stirring, and place it for use. Add hydroxyethyl methacrylate (HEMA) and N-vinylpyrrolidone (NVP) monomers according to the ratio of the amount of substances to 7.4:2, and then add the above-mentioned water-soluble graphene oxide solution to make the graphene oxide aqueous solution Accounting for 35% of the total mass of the whole monomer and graphene oxide aqueous solution mixture, add 0.5% (M APS+TMEDA :M HEMA+NVP ) ammonium persulfate (APS) and tetramethylethylenediamine (TMEDA) redox initiator, stirred evenly and poured into the mold, reacted at 60°C for 1 hour, soaked in water for demoulding, and obtained graphene oxide composite water gel. The gel time of this hydrogel is 29±2min, no obvious deformation occurs after swelling, and the equilibrium water content is 47±1%. The hydrogel was soaked in a 0.5 mg / ml puerarin aqueous s...

Embodiment 2

[0057] Add F-127 to the 0.5 mg / mL graphene oxide aqueous dispersion to make the final F-127 concentration 12.5 mg / mL, disperse it evenly by magnetic stirring, and place it for use. Add hydroxyethyl methacrylate (HEMA) and N-vinylpyrrolidone (NVP) monomers according to the ratio of the amount of substances to 7.4:2, and then add the above-mentioned water-soluble graphene oxide solution to make the graphene oxide aqueous solution Accounting for 35% of the total mass of the whole monomer and graphene oxide aqueous solution mixture, add 0.5% (M APS+TMEDA :M HEMA+NVP ) ammonium persulfate (APS) and tetramethylethylenediamine (TMEDA) redox initiator, stirred evenly and poured into the mold, reacted at 60°C for 1 hour, soaked in water for demoulding, and obtained graphene oxide composite water gel. The gel time of this hydrogel is 29±2min, no obvious deformation occurs after swelling, and the equilibrium water content is 47±1%. The hydrogel was soaked in a 0.5 mg / ml puerarin aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com