Preparation method of indole-modified macroporous carbon supported transition metal catalysts

A transition metal, macroporous carbon technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of less research and poor catalyst performance, and achieve good conductivity, uniform distribution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

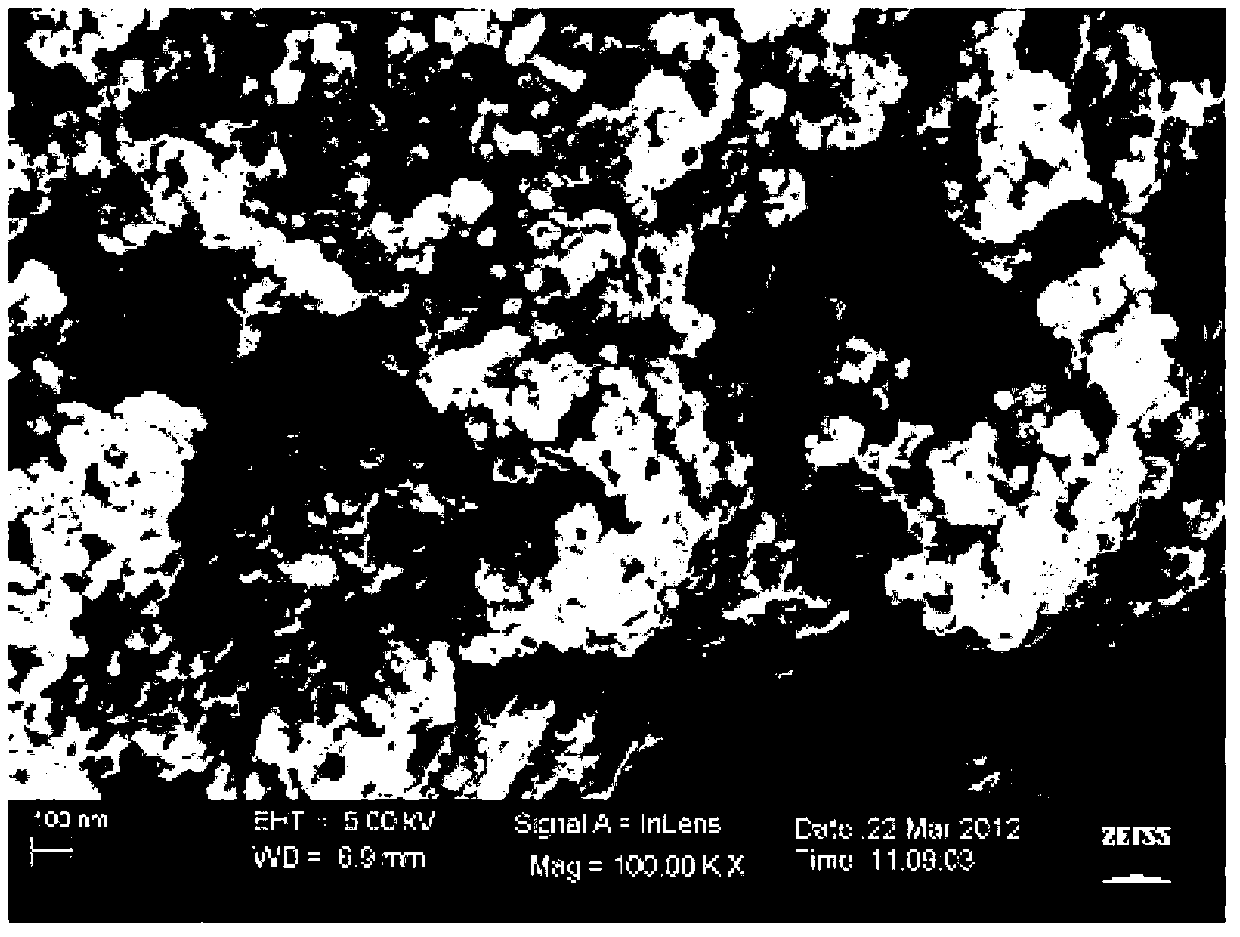

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of macroporous carbon

[0021] Weigh the hydrophilic nano-CaCO according to the mass ratio of 1:1 3 (15-40 nm) and 10 g of glucose each, add 100 mL of deionized water, and mix with ultrasonic vibration for 30 minutes to dissolve the carbon source material and mix with nano-CaCO 3 Disperse evenly, heat to evaporate water, and then cure at 160°C for 6 hours. The cured product was heated to 800 °C under the protection of nitrogen atmosphere, and carbonized at constant temperature for 2 hours. The carbonized product was successively washed with 5 wt% hydrochloric acid, 80 o C was washed with sodium hydroxide solution (concentration: 30 wt%) and deionized water, and dried at a constant temperature at 120 °C for 4 hours to obtain macroporous carbon materials.

[0022] When glucose is replaced by sucrose, starch, cyclodextrin, polyvinyl alcohol, polyethylene glycol, polyacrylic acid, and water-soluble cellulose in sequence, the pore size and porosity...

Embodiment 2

[0023] Example 2: Preparation of indole-modified macroporous carbon-supported noble metal catalyst

[0024] Weigh the hydrophilic nano-CaCO according to the mass ratio of 1:1 3 (15-40 nm) and 10 g of sucrose each, add 100 mL of deionized water, and mix with ultrasonic vibration for 30 minutes to dissolve the carbon source material and mix with nano-CaCO 3 Disperse evenly, heat to evaporate water, and then cure at 160°C for 6 hours. The cured product was heated to 800 °C under the protection of nitrogen atmosphere, and carbonized at constant temperature for 2 hours. The carbonized product was successively washed with 5 wt% hydrochloric acid, 80 o C was washed with sodium hydroxide solution (concentration: 30 wt%) and deionized water, and dried at a constant temperature at 120 °C for 4 hours to obtain macroporous carbon materials.

[0025] The macroporous carbon material was crushed to a particle size of 100-400 mesh, 2 g of macroporous carbon was placed in a hydrothermal re...

Embodiment 3

[0026] Example 3: Preparation of indole-modified macroporous carbon-supported non-noble metal catalyst

[0027] Weigh the hydrophilic nano-CaCO according to the mass ratio of 1:1 3 (15-40 nm) and 10 g of starch each, add 100 mL of deionized water, and mix with ultrasonic vibration for 30 minutes to dissolve the carbon source material and mix with nano-CaCO 3 Disperse evenly, heat to evaporate water, and then cure at 160°C for 6 hours. The cured product was heated to 800 °C under the protection of nitrogen atmosphere, and carbonized at constant temperature for 2 hours. The carbonized product was successively washed with 5 wt% hydrochloric acid, 80 o C was washed with sodium hydroxide solution (concentration: 30 wt%) and deionized water, and dried at a constant temperature at 120 °C for 4 hours to obtain macroporous carbon materials.

[0028] The macroporous carbon material was crushed to a particle size of 100-400 mesh, and 2 g of macroporous carbon was placed in a hydrothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com