Method for preparing long-chain alkyl ammonium hydroxide

A long-chain alkyl and ammonium hydroxide technology, which is applied in the preparation of amino compounds from amines, organic chemistry, electrolysis process, etc., can solve the problems of low purity, large amount of resin, serious environmental pollution, etc., and achieve surface activity, The effect of low equipment requirements and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

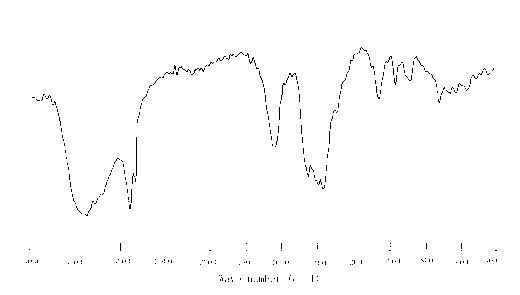

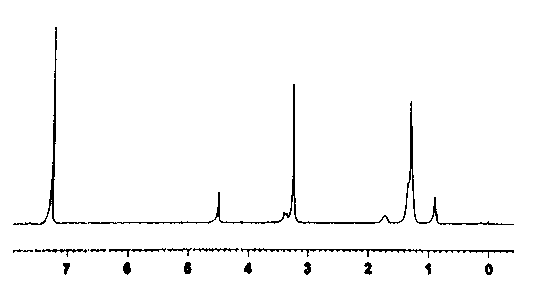

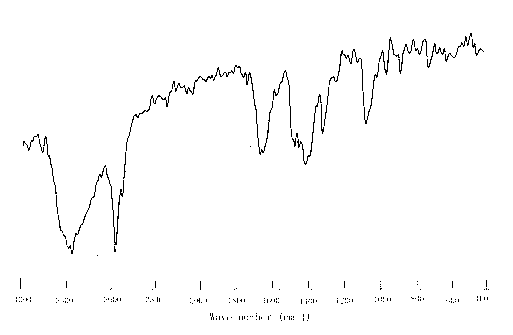

Image

Examples

Embodiment 1

[0035] Example 1: 110.2g of dodecyldimethyl tertiary amine, 190.7g of dimethyl carbonate and 15.2g of methanol were added to the reaction kettle, stirred and reacted at 120°C for 8h, after the reaction was completed, the mixture was distilled off under reduced pressure Methanol and dimethyl carbonate to obtain ammonium dodecyl methyl ammonium carbonate, weigh 20.7g ammonium dodecyl methyl ammonium carbonate and 103.7g water, add them to the flask, stir and react at 70°C for 3h, and obtain dodecyl trimethyl ammonium carbonate Methyl ammonium bicarbonate aqueous solution, dodecyl trimethyl ammonium bicarbonate is prepared into a solution with a concentration of 0.8mol / L, and added to the anode of a single-membrane two-chamber electrolytic cell equipped with a polystyrene sulfonic acid membrane cation exchange membrane In the chamber, the cathode chamber is filled with deionized water, the anode is a titanium electrode coated with ruthenium oxide, the cathode is a stainless steel ...

Embodiment 2

[0036] Example 2: 107.3g of didodecylmethyl tertiary amine, 70.3g of dimethyl carbonate and 27.3g of methanol were added to the reaction kettle, stirred and reacted at 140°C for 7h, after the reaction was completed, the mixture was distilled off under reduced pressure Methanol and dimethyl carbonate to obtain didodecyl ammonium methyl ammonium carbonate, weigh 19.5g didodecyl methyl ammonium carbonate and 138.3g water, add them to a flask, stir and react at 60°C for 5h, and obtain didodecyl ammonium methyl ammonium carbonate Alkyl dimethyl ammonium bicarbonate aqueous solution, didodecyl dimethyl ammonium bicarbonate is prepared into a solution with a concentration of 0.8mol / L, and added to a single-membrane two-chamber electrolysis chamber equipped with a perfluorosulfonic acid membrane cation exchange membrane In the anode chamber of the tank, add 0.02mol / L dodecyl dimethyl ammonium hydroxide solution to the cathode chamber, the anode is a titanium electrode coated with iridi...

Embodiment 3

[0037] Example 3: 105.6g of dodecyl dimethyl tertiary amine, 77.9g of dimethyl carbonate and 21.8g of methanol were added to the reaction kettle, stirred and reacted at 100°C for 20h, after the reaction was completed, it was removed by distillation under reduced pressure Methanol and dimethyl carbonate to obtain ammonium dodecyl methyl ammonium carbonate. Weigh 17.3g of ammonium dodecyl methyl ammonium carbonate and 156.0g of water, add them to a flask, stir and react at 30°C for 7h, and obtain dodecyl ammonium methyl ammonium carbonate. Aqueous solution of methyl ammonium bicarbonate, dodecyl trimethyl ammonium bicarbonate is prepared into a solution with a concentration of 0.55mol / L, and added to the anode chamber of a single-membrane two-chamber electrolyzer equipped with a perfluorocarboxylic acid cation exchange membrane , add 0.5mol / L dodecyltrimethylammonium hydroxide solution in the cathode chamber, the anode is a titanium electrode coated with ruthenium oxide, the cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com