Goose oil diacylglycerol microcapsules

A technology for goose oil diglyceride and diglyceride, which is applied in the field of oil microcapsule preparation, can solve the problems of inconvenience in transportation, storage and consumption, poor fluidity, and unfavorable market sales of goose oil diglyceride, and achieves the improvement of microcapsule packaging. The effect of improving the burial rate, production efficiency, stability and convenience, and broadening the market of goose oil utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 1) Preparation of mixed fatty acids: Add the refined goose oil into 1mol / L NaOH-ethanol solution in a ratio of 1:4, stir magnetically for a period of time to completely dissolve it, then transfer it to a 1000ml three-neck flask, reflux in a water bath for saponification for a period of time, To obtain a saponified solution, distill ethanol out under reduced pressure, add water to completely dissolve the saponified product, acidify with 10% HCl to pH 2-3 under constant temperature and constant speed stirring, add a certain volume of n-hexane for extraction, wash with warm water until neutral, reduce Evaporate the solvent under pressure, add anhydrous sodium sulfate for dehydration, and filter with suction to obtain mixed fatty acids. Wherein, the preparation conditions of the mixed fatty acid are: saponification temperature 82° C., reaction time 60 minutes.

[0036] 2) Preparation of diglycerides: Weigh glycerol and mixed fatty acids in a small flask at a ratio of 1:1.05...

Embodiment 1

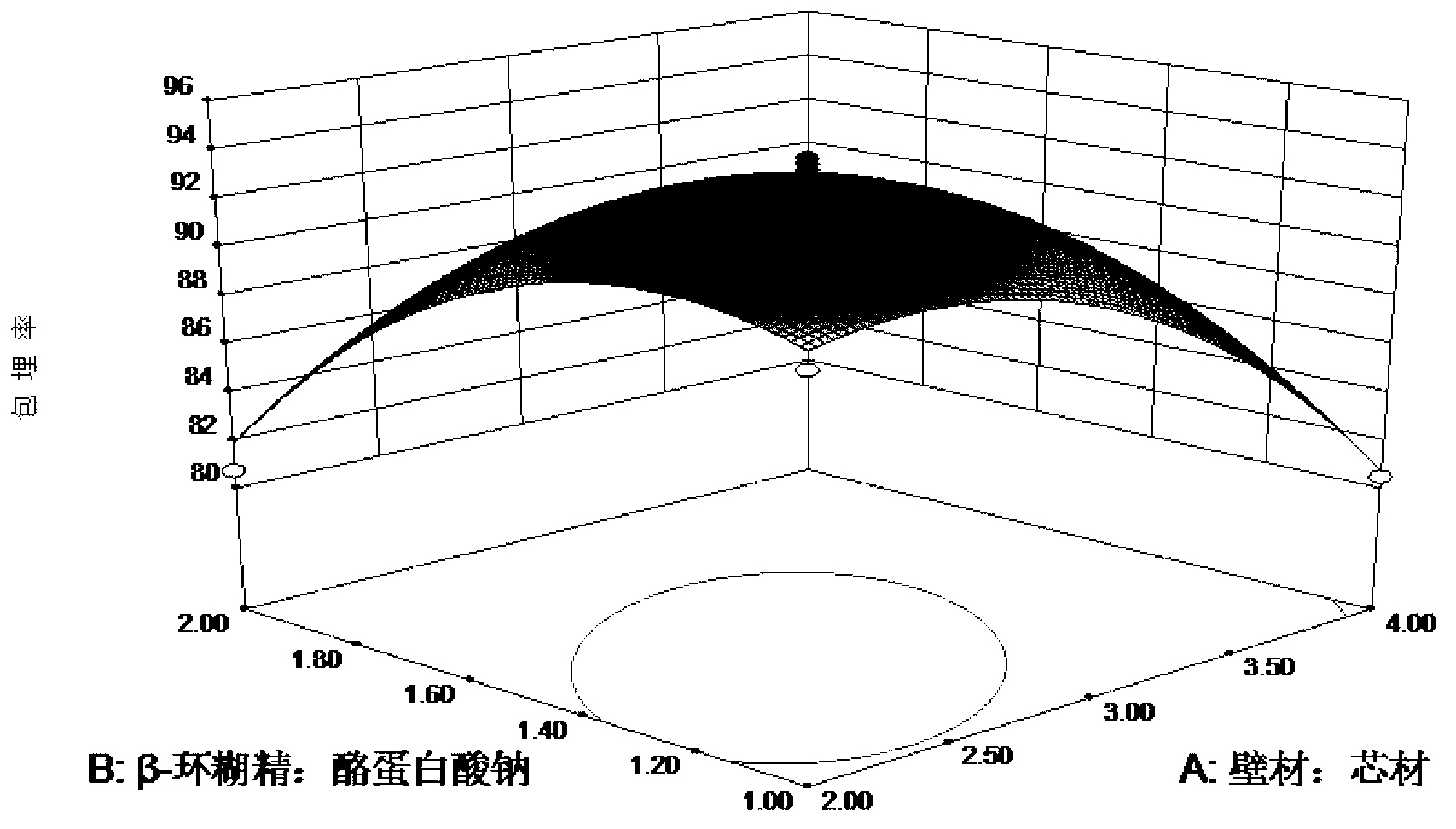

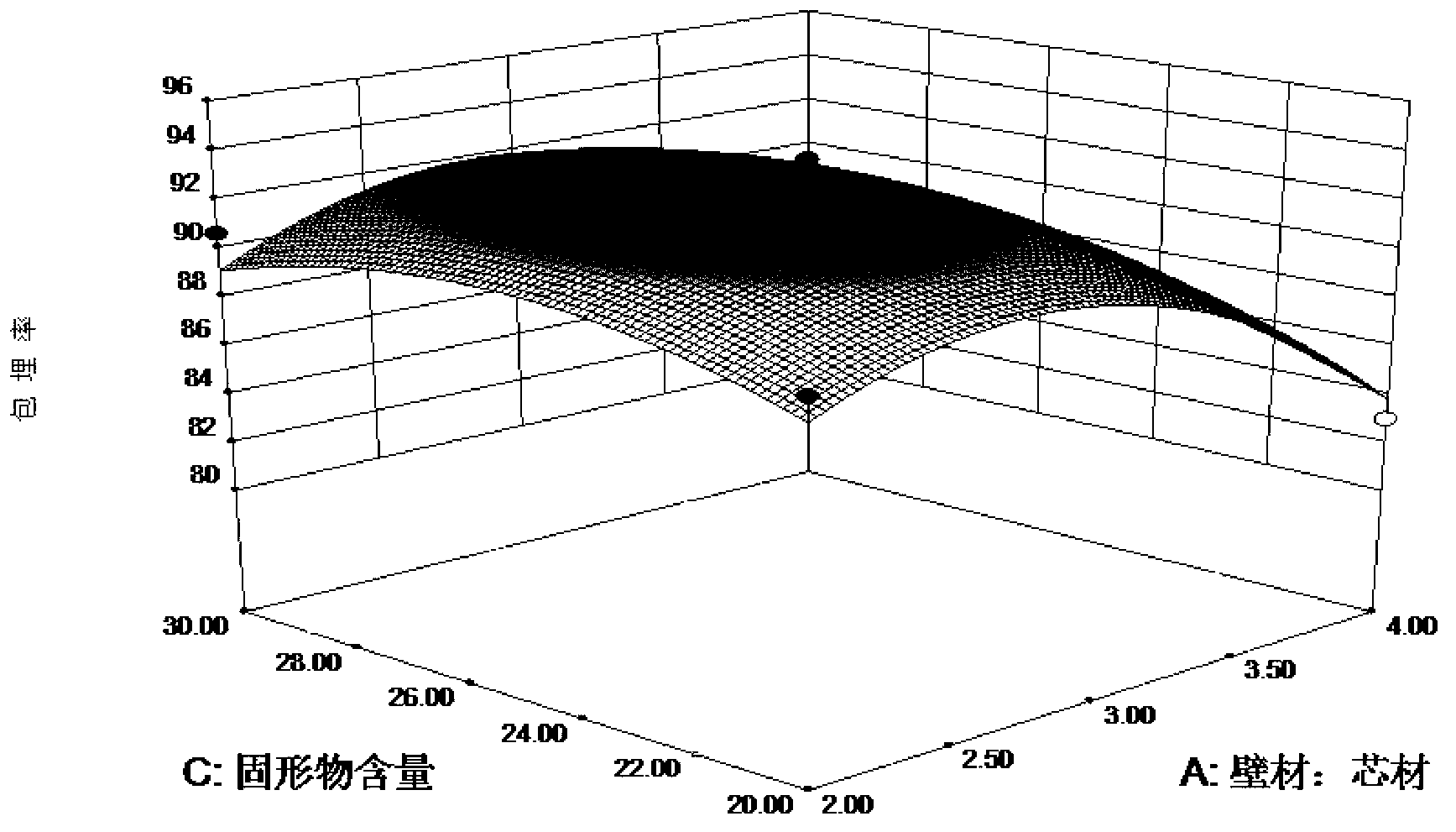

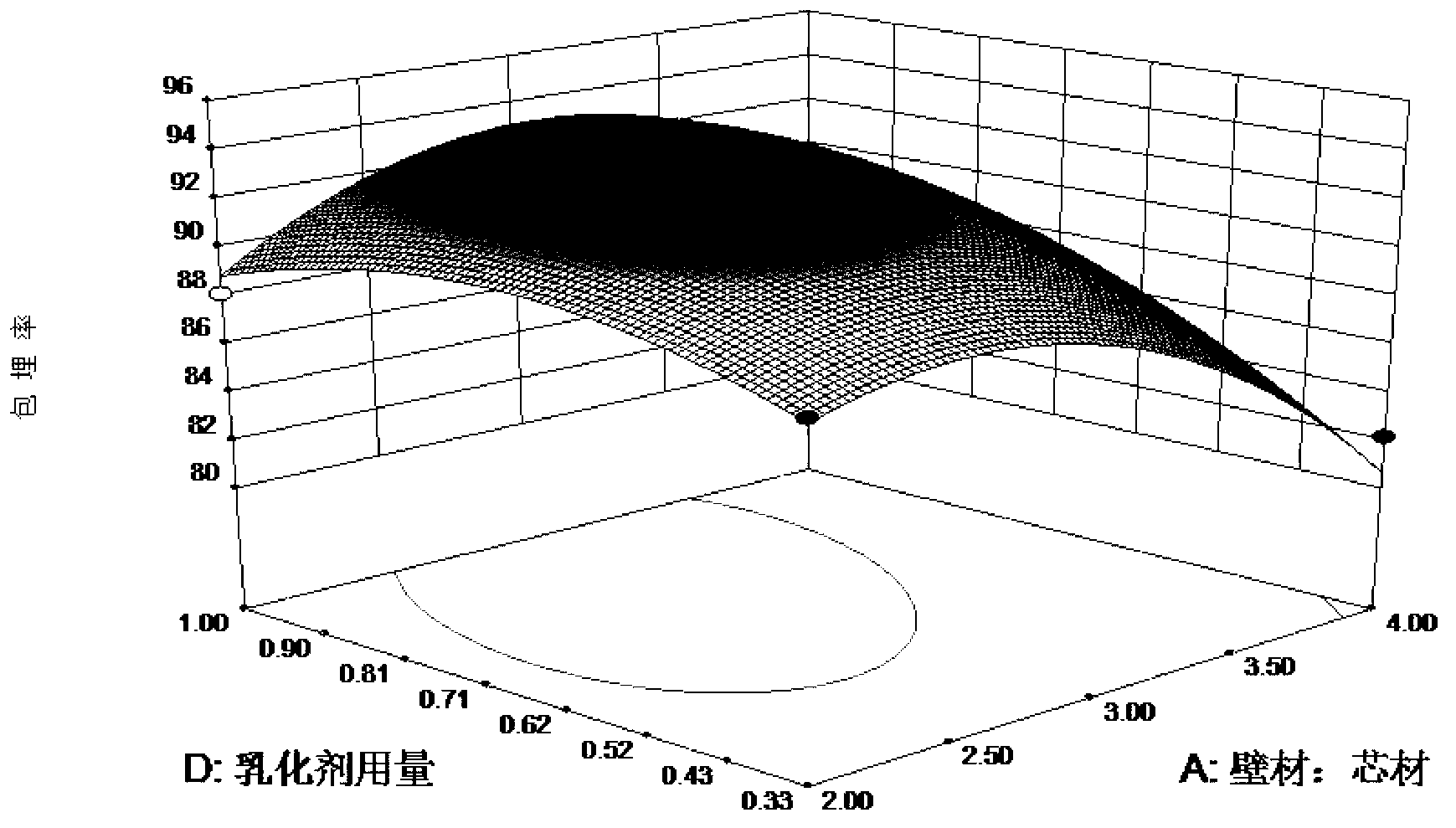

[0043] Embodiment 1: Microencapsulation optimal process condition screening test

[0044] (1) Preparation of emulsion

[0045] Dissolve β-cyclodextrin and sodium caseinate in water at a mass ratio of 1.5:1, and ultrasonically treat it for 3 minutes. After it is fully dissolved, add 1% sodium carboxymethylcellulose (CMC), and stir The goose oil diglyceride after ultrasonic treatment is slowly added to make it fully and homogeneously mixed.

[0046] (2) Emulsion freeze-drying treatment

[0047] Pour the emulsion into a plastic petri dish, pre-cool at minus 40°C, put it in a freeze dryer for 15 hours and then take it out.

[0048] (3) Determination of microcapsule embedding rate

[0049] ① Determination of oil content on the surface of microcapsules: Take 2.0g sample, add 50ml of petroleum ether, shake vigorously for 2 minutes, filter with suction, collect the filtrate and evaporate the solvent in a rotary evaporator, and measure the surface oil quality by weight loss method. ...

Embodiment 2

[0073] Embodiment 2: Microencapsulation optimal process condition regression test

[0074] Add 134g of β-cyclodextrin into distilled water preheated to 50°C to dissolve completely, then slowly add 110g of sodium caseinate according to the ratio of β-cyclodextrin to sodium caseinate at 1.22:1, and wait until it is fully After dissolving, 7.56 g of sodium carboxymethylcellulose (CMC) equivalent to 0.7% by mass was added, and 100 g of goose oil diglyceride was slowly added under high-speed stirring and then homogenized. Pour the emulsion into a plastic petri dish, pre-cool at minus 40°C, put it in a freeze dryer for 15 hours and take it out. The conditions for vacuum freeze-drying are: -40°C and 80Pa. After 5 repeated tests, the embedding rates of the obtained microcapsule products were 93.27%, 93.45%, 93.37%, 93.26%, and 93.05%, respectively, and the average embedding rate was 93.28%, which was basically consistent with the results of the implementation case 1; The invented pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com