Degradable high polymer reticular balloon for vertebral fracture treatment and preparation method of balloon

A polymer and polymer material technology, applied in the field of degradable polymer mesh balloon and its preparation, can solve the problem of non-degradable, clinical use of calcium phosphate bone cement, and failure to prevent calcium phosphate bone cement from collapsing in water. To achieve the effect of promoting the formation of new bone, expanding the scope of application of surgery, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Materials and Methods

[0029] 1. Materials

[0030] Block copolymer P (DLLA-CL) (70:30) (other materials, ratio) was purchased from Shandong Jinan Daigang Biomaterials Co., Ltd., dissolved in dichloromethane / dimethylformamide (7:3, volume ratio ), the concentration is 6 wt%.

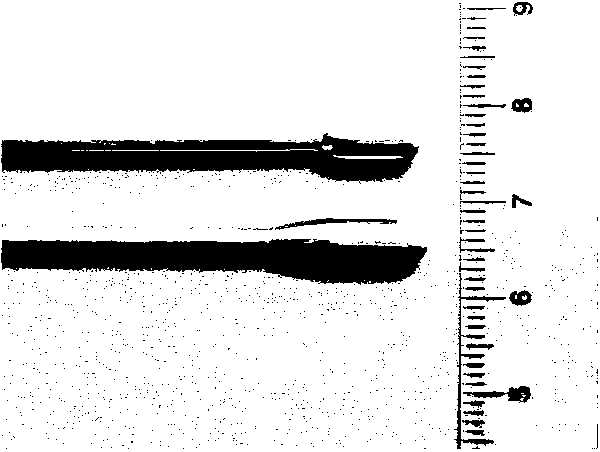

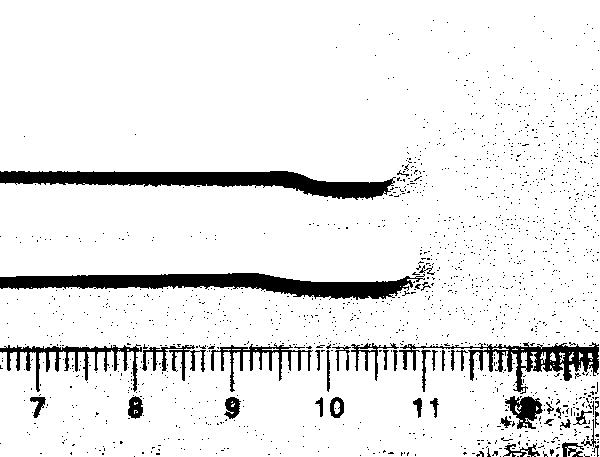

[0031] 2. Electrospinning conditions

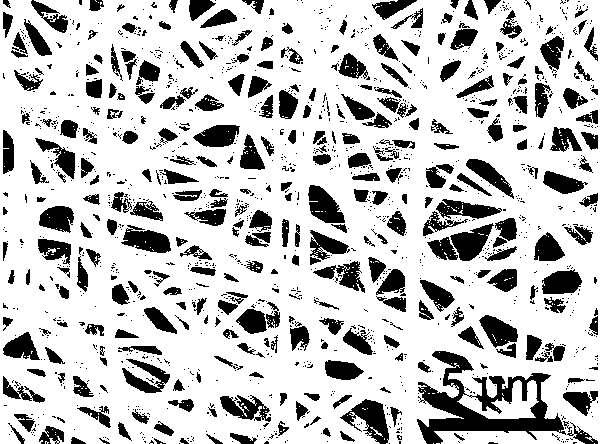

[0032] see figure 1 and figure 2 , the polymer solution is put into a 10mL glass syringe with a 0.9mm inner diameter injection needle at the front end, the injection rate is 0.3mL / h, and the voltage is 10kV; the receiving device is a titanium alloy rod, the distance between the injector outlet and the receiving device The speed of the receiving device is 10 cm, and the rotating speed of the receiving device is 15 rpm; the ejected fibers can be collected to obtain a degradable polymer mesh balloon on the receiving device. The prepared balloon was removed and dried in vacuum for 12 hours and then stored at room temperature. Immerse in medical sterile wa...

Embodiment 2

[0090] Weigh 0.7 g of polylactic acid and 0.3 g of polycaprolactone, put them into a mixed solvent of 10 mL of methanol and dichloromethane, and stir on a magnetic stirrer at room temperature until the copolymer is completely dissolved and the solution is transparent; The above solution was loaded into the syringe in the spray device so that the injection rate was 0.3mL / h, a high voltage of 10kV was generated between the positive electrode of the needle tip and the negative electrode of the substrate, and the distance between the needle tip and the receiving device was 12cm. figure 1 The collector (titanium alloy rod) shown in , collects the fibers extruded by electrospinning to prepare the balloon.

Embodiment 3

[0092] Weigh 0.7 g of polylactic acid and 0.3 g of polycaprolactone, put them into a mixed solvent of 10 mL of methanol and dichloromethane, and stir on a magnetic stirrer at room temperature until the copolymer is completely dissolved and the solution is transparent; The above solution was loaded into the syringe in the spray device so that the injection rate was 0.3mL / h, a high voltage of 10kV was generated between the positive electrode of the needle tip and the negative electrode of the substrate, and the distance between the needle tip and the receiving device was 12cm. figure 1 The collector (titanium alloy rod) shown in , collects the fibers extruded by electrospinning to prepare the balloon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com