Method for rapidly and nondestructively transferring graphene

A graphene, fast technology, applied in the field of fast and non-destructive transfer of graphene, can solve the problems of graphene structure damage, time-consuming, environmental pollution, etc., achieve the effect of good monolayer and uniformity, and avoid organic glue residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The graphene transferred in this embodiment is grown on the copper foil growth substrate by CVD method, the growth temperature is 1000° C., the pressure is low pressure, the protective gas and carbon source are respectively nitrogen and methane, and the growth time is 30 minutes.

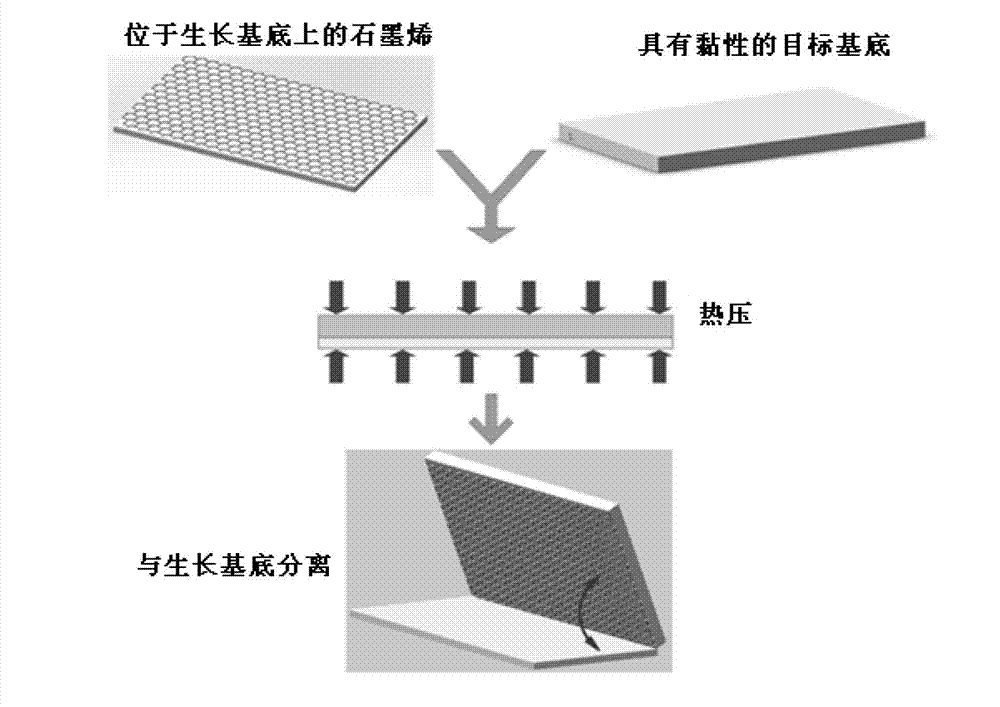

[0025] like figure 1 Shown, the method for the rapid lossless transfer graphene of the present embodiment, comprises the following steps:

[0026] 1) Select polystyrene as the target substrate, first perform plasma etching on the surface of the target substrate, generate oxygen-containing functional groups on the surface of the target substrate, these groups can promote adhesion, and then coat the surface of the target substrate with thermosetting epoxy resin;

[0027] 2) Paste the surface of the target substrate coated with thermosetting epoxy resin obtained in step 1) on graphene to form a composite structure of target substrate / graphene / growth substrate;

[0028] 3) Carry out hot pressin...

Embodiment 2

[0031] The graphene transferred in this embodiment is grown on the copper foil growth substrate by CVD method, the growth temperature is 800° C., the pressure is low pressure, the protective gas and carbon source are respectively nitrogen and ethylene, and the growth time is 50 min.

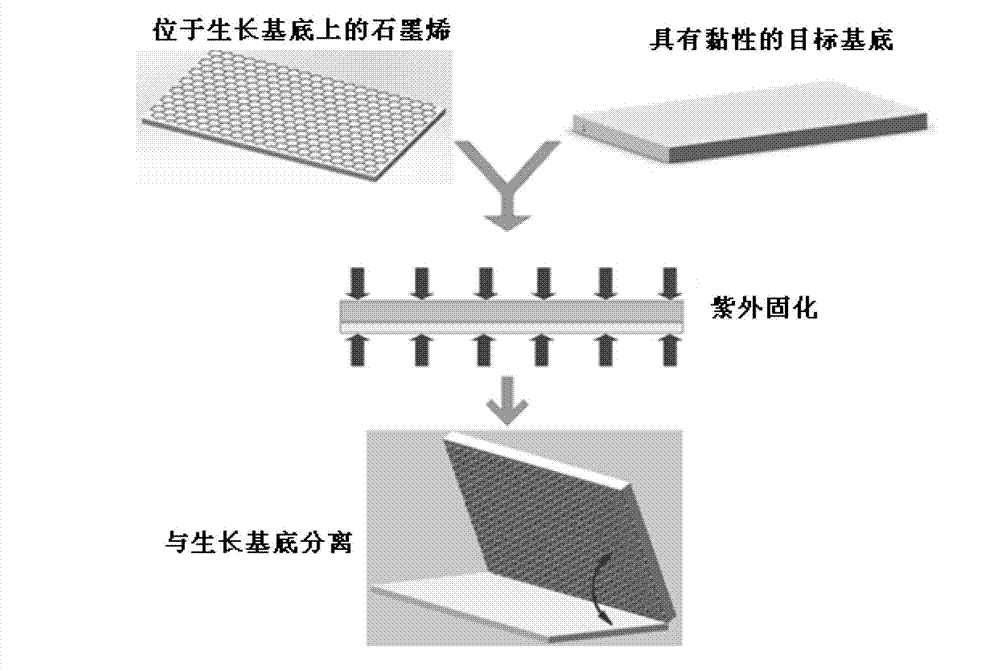

[0032] like figure 2 Shown, the method for the rapid lossless transfer graphene of the present embodiment, comprises the following steps:

[0033] 1) Choose polyethylene terephthalate as the target substrate, first pickle and alkali wash the surface of the target substrate, generate oxygen-containing functional groups on the surface of the target substrate, these groups can promote adhesion, and then Coating light-curable polyacrylate on the target substrate surface;

[0034] 2) Paste the surface of the target substrate coated with photocurable polyacrylate obtained in step 1) on graphene to form a composite structure of target substrate / graphene / growth substrate;

[0035] 3) Perform ultraviol...

Embodiment 3

[0038] The graphene transferred in this embodiment is grown on the nickel foil growth substrate by CVD method, the growth temperature is 600° C., the pressure is low pressure, the protective gas and carbon source are respectively nitrogen and acetylene, and the growth time is 40 min.

[0039] like figure 1 Shown, the method for the rapid lossless transfer graphene of the present embodiment, comprises the following steps:

[0040] 1) Select polymethyl methacrylate as the target substrate, first treat the surface of the target substrate with ozone, and generate oxygen-containing functional groups on the surface of the target substrate. These groups can promote adhesion, and then coat the surface of the target substrate Thermosetting unsaturated polyester;

[0041] 2) Paste the surface of the target substrate coated with thermosetting unsaturated polyester obtained in step 1) on graphene to form a composite structure of target substrate / graphene / growth substrate;

[0042] 3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com