Preparation method of ultrawhite, easily dispersible and high stability powder special for water-based paint

A water-based coating, easy-to-disperse technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of high processing cost, coarse powder particle size, high labor intensity, etc. The effect of fine particle size and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

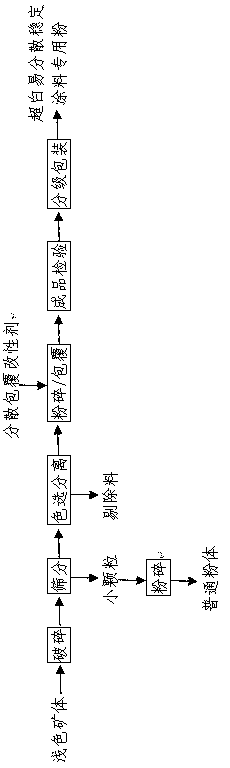

Image

Examples

Embodiment 1

[0034] A method for preparing a special powder for ultra-white, easy-to-disperse and highly stable water-based coatings, the steps of which are as follows:

[0035] ① Add CaCO3 Content ≥ 90%, Fe 2 o 3 1050kg of light-colored calcite blocks with a content of 1.50% are crushed into pellets with a particle size of <6mm by a crusher;

[0036] ②Sieve the granular material with a screening machine with apertures of 2×2mm and 6×6mm double-layer screens to obtain 1000kg of granular material with a particle size distribution of 2mm-6mm, and return the granular material >6mm to the crushing system to continue crushing. Pellets <2mm are crushed and used to make ordinary powder;

[0037] ③ Use a color difference sorting machine with digital camera, digital signal processing, high-pressure airflow, air gun, separation slide, and material collection device to electromechanically sort and separate calcite particles with variegated particles, and control the whiteness of the finished produc...

Embodiment 2

[0041] A method for preparing a special powder for ultra-white, easy-to-disperse and highly stable water-based coatings, the steps of which are as follows:

[0042] ① Add CaMg (CO 3 ) 2 Content ≥ 90%, Fe 2 o 3 1040kg of light-colored dolomite blocks with a content of 0.60% are crushed into pellets with a particle size of <5mm;

[0043] ②Sieve the granular material with a screening machine with apertures of 1×1mm and 5×5mm double-layer screens to obtain 1000kg of granular material with a particle size distribution of 1mm-5mm, and return the granular material >5mm to the crushing system to continue crushing. Pellets <1mm are crushed and used to make ordinary powder;

[0044] ③A color difference sorting machine with digital camera, digital signal processing, high-pressure airflow, air gun, separation slide, and material collection device is used to electromechanically sort and separate dolomite particles with variegated particles. Degree 96% requirement, select Fe 2 o 3 Co...

Embodiment 3

[0048] A method for preparing an ultra-white, easily dispersed and highly stable water-based paint special powder, the steps of which are as follows:

[0049] ①CaSiO 3 Content ≥ 90%, Fe 2 o 3 1035kg of light-colored wollastonite blocks with a content of 0.40% are crushed into pellets with a particle size of <5mm;

[0050] ②Sieve the granular material with a screening machine with apertures of 1×1mm and 5×5mm double-layer screens to obtain 1000kg of granular material with a particle size distribution of 1mm-5mm, and return the granular material >5mm to the crushing system to continue crushing. Pellets <1mm are crushed and used to make ordinary powder;

[0051] ③ Use a color difference sorting machine with digital camera, digital signal processing, high-pressure airflow, air gun, separation slide, and material collection device to electromechanically sort and separate wollastonite particles with variegated particles, and control the finished product according to the plan Whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com