Homogeneous anion-exchange membrane and preparation method thereof

The technology of anion exchange membrane and crosslinking agent is applied in the field of homogeneous anion exchange membrane and its preparation. , The effect of stable homogeneous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

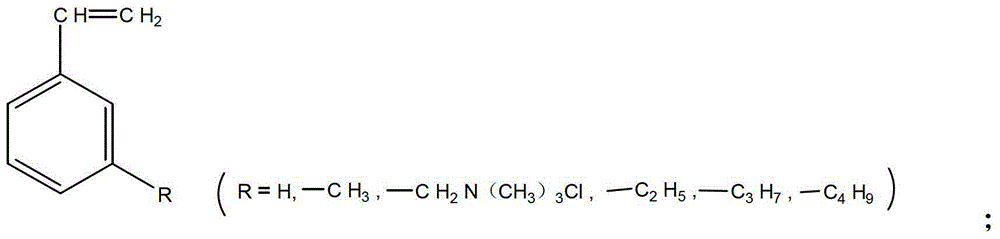

Problems solved by technology

Method used

Image

Examples

Embodiment 1

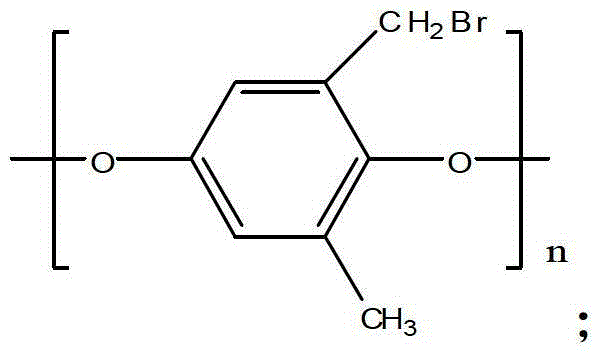

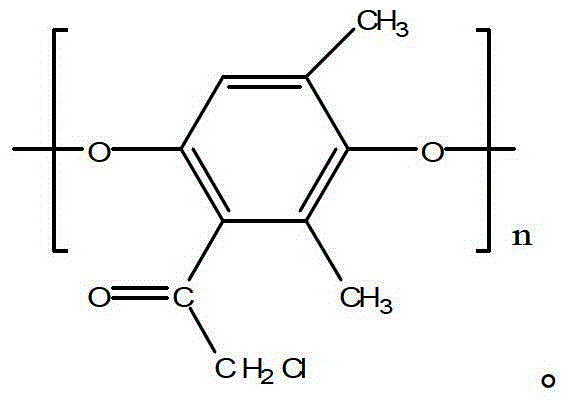

[0020] Dissolve 3g of methyl brominated polyphenylene ether in 9ml of N,N dimethylformamide solution at 50°C, and pass trimethylamine gas into it for 4 hours under mechanical stirring to obtain a casting solution, and coat the film on a glass plate at 60°C After drying, the anion exchange membrane is obtained.

[0021] Carry out infrared test to above-mentioned brominated polyphenylene ether, the result is: 500-600cm -1 Corresponding to the stretching vibration peak of C-Br in brominated polyphenylene ether, 3,000-3,100cm -1 and 1620-1580 respectively correspond to the C-H and C-C stretching vibration peaks of the benzene ring, indicating the presence of a bromomethyl group. After dissolving and aminating it, at 990-810cm -1 The new peaks that appear correspond to N + -(CH 3 ) 3 , demonstrating the presence of quaternary ammonium groups.

[0022] Water content and ion exchange capacity tests showed that the water content and anion exchange capacity of the quaternized mem...

Embodiment 2

[0024] Using the same operation process as in Example 1, except that the solvent N, N dimethylformamide was replaced by 9 ml of N methylpyrrolidone, a film with a similar structure was obtained.

[0025] It is measured that the water content and ion exchange capacity of the anion exchange membrane prepared by the present embodiment are 86% and 2.19mmol / g-dry film respectively, and the membrane resistance is 2.24Ω·cm 2 , the ion mobility number is 0.93.

Embodiment 3

[0027] The same operation process as in Example 1 was adopted, but the solvent was replaced with 9 ml of a 1:1 mixed solvent of N, N dimethylformamide and N methylpyrrolidone. A membrane with a similar structure was obtained.

[0028] It is measured that the water content and ion exchange capacity of the anion exchange membrane prepared in this embodiment are 88% and 2.25mmol / g-dry film respectively, and the membrane resistance is 1.98Ω·cm 2 , the ion mobility number is 0.92. Experimental data show that the membrane has good conductivity and high anion selectivity, and can be applied in the field of electrodialysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com