Preparation method of acetyl tri-n-butyl citrate and catalyst used in preparation method

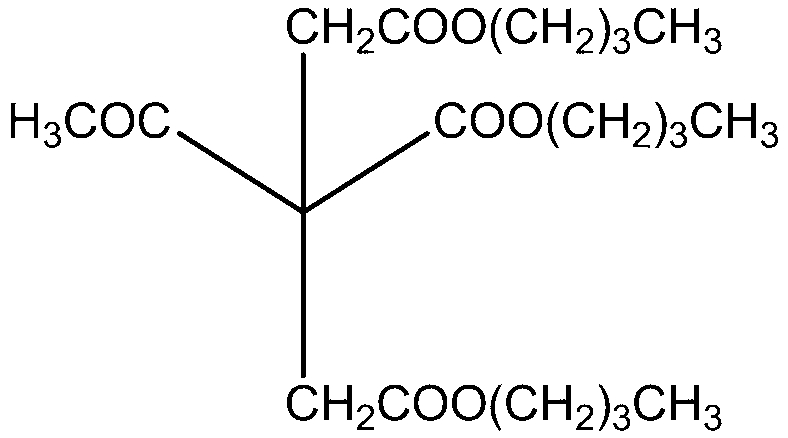

A technology of acetyl tri-n-butyl citrate and citric acid, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, and physical/chemical process catalysts, etc., to achieve high production efficiency, high catalytic activity, and low corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

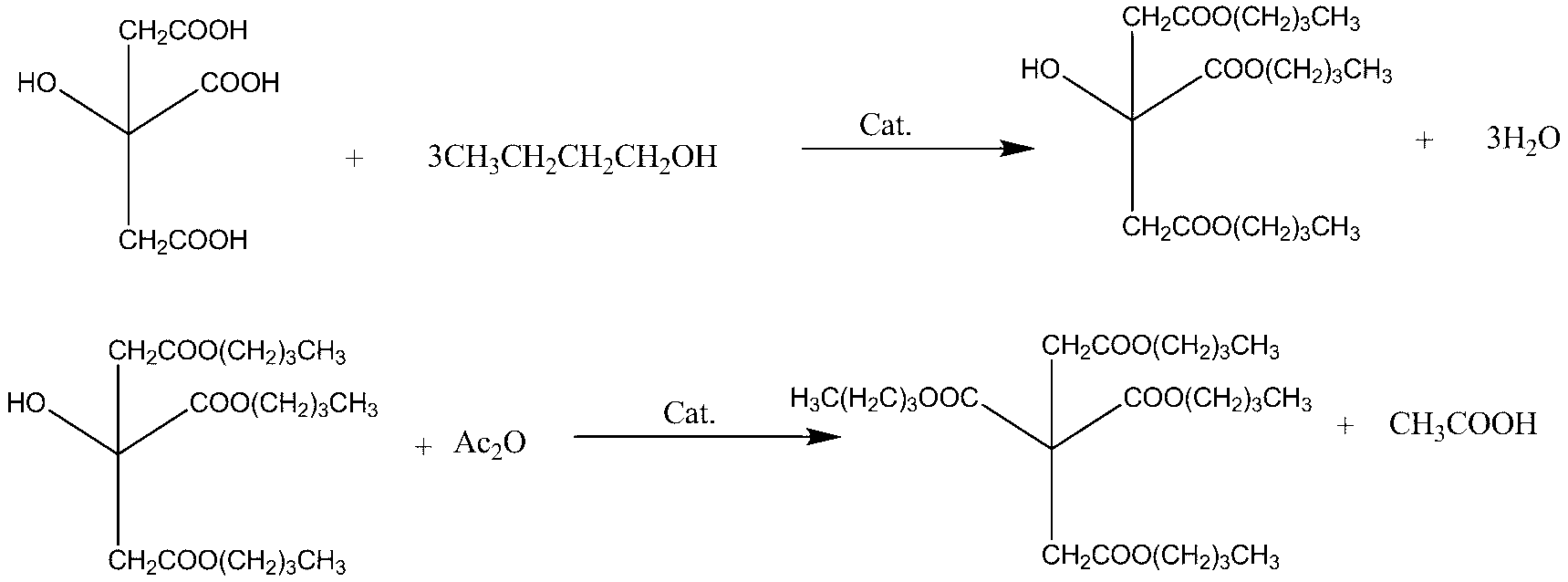

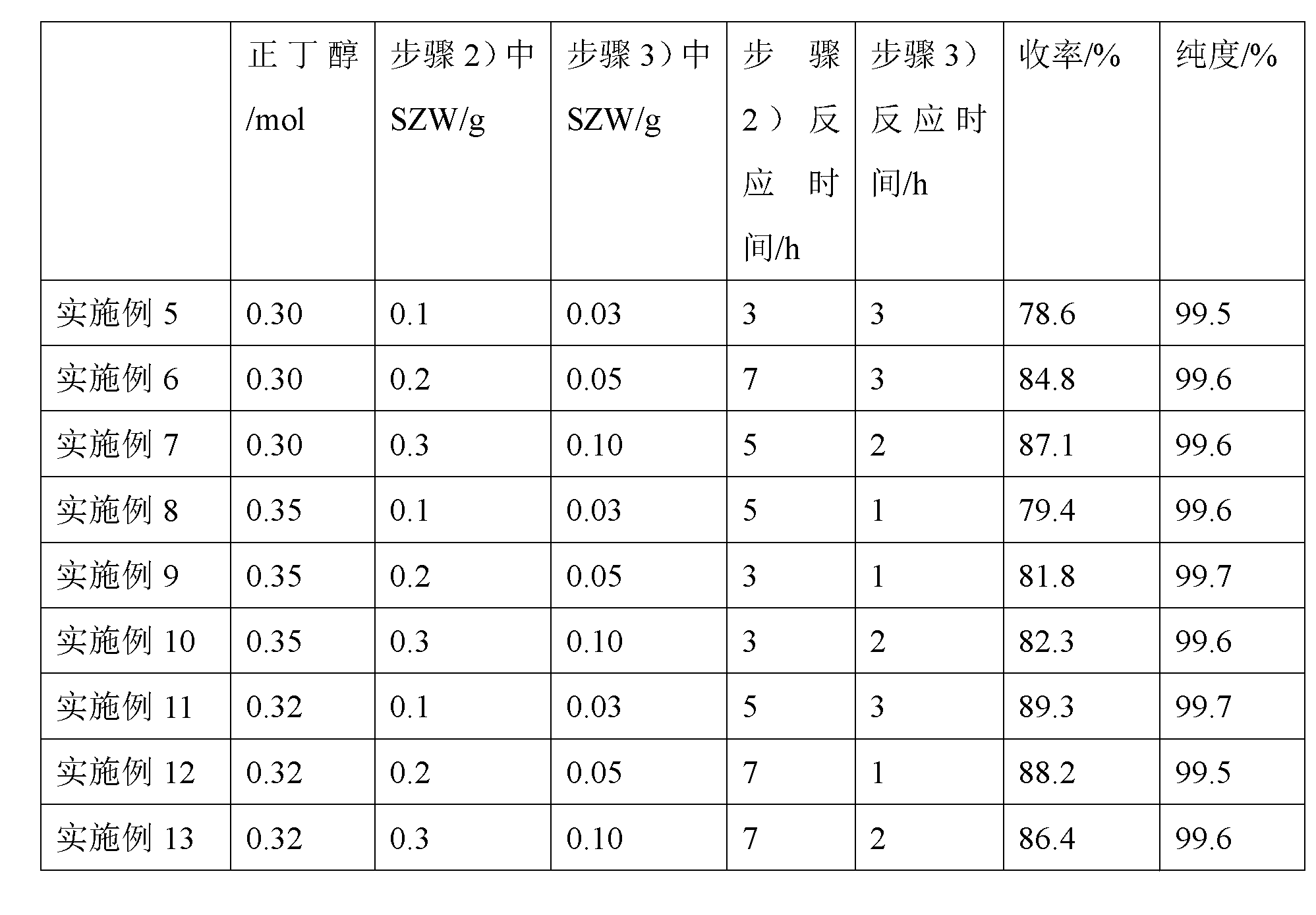

[0033] Embodiment 1, a kind of preparation method of organic compound---acetyl tri-n-butyl citrate, take citric acid, n-butanol as raw material, carry out following steps successively:

[0034] 1) Solid superacid SO as a catalyst 4 2- / ZrO 2 -WO 3 (SZW) preparation, carry out following steps successively:

[0035] ①. Weigh 5g of ZrOCl 2 ·8H 2 O is dissolved in deionized water (about 20ml), and the mass ratio M(ZrOCl 2 ): M(H 2 O)=1:8 ZrOCl 2 Aqueous solution; slowly add ammonia water to the above solution to adjust the pH to 9.

[0036] ②. Stir the mixture obtained in step ① for 25 min at room temperature, put it in an oven, and age it at 80°C for 36 h; filter, and wash the obtained filter cake with water until it is free of Cl - Then, it was placed in a muffle furnace and fired at 550 °C for 12 h.

[0037] ③. After cooling the roasted product obtained in step ② to room temperature, grind it into a powder that can pass through 100 mesh (pass through a 100 mesh sieve)...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of organic compound---acetyl tri-n-butyl citrate, with citric acid, n-butanol is raw material, carries out following steps successively:

[0044] 1) Solid superacid SO as a catalyst 4 2- / ZrO 2 -WO 3 (SZW) preparation:

[0045] With embodiment 1.

[0046] 2) React 0.1mol of citric acid, 0.3mol of butanol, 0.10g of SZW and 100ml of toluene in a 250ml three-neck flask under the condition of reflux and water separation, and continuously separate water during the reaction. After 3 h of reaction, the reaction was stopped, and the reaction solution was cooled to room temperature.

[0047] 3) Add 0.1 mol of acetic anhydride and 0.05 g of SZW to the reaction solution cooled to room temperature, and react at room temperature for 1 hour. Filter out the catalyst and reuse it. The filtrate was distilled under reduced pressure to remove toluene, a small amount of unreacted n-butanol and acetic acid produced in the reaction, and the s...

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of organic compound---acetyl tri-n-butyl citrate, with citric acid, n-butanol is raw material, carries out following steps successively:

[0049] 1), solid superacid SO 4 2- / ZrO 2 -WO 3 (SZW) catalyst preparation:

[0050] With embodiment 1.

[0051] 2) React 0.1mol citric acid, 0.35mol n-butanol, 0.20g SZW and 100ml toluene in a 250ml three-necked flask under the condition of reflux and water separation, and continuously separate water during the reaction. After 5 hours of reaction, the reaction was stopped, and the reaction solution was cooled to room temperature.

[0052] 3) Add 0.1 mol of acetic anhydride and 0.05 g of SZW to the reaction solution cooled to room temperature, and react at room temperature for 2 hours. Filter out the catalyst and reuse it. The filtrate was distilled under reduced pressure to remove toluene, a small amount of unreacted n-butanol and acetic acid produced in the reaction, and the still l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com