Preparation method of sodium alginate-xanthan gum modified nano A zeolite assembly

A technology of sodium alginate and xanthan gum, applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems of high price, toxicity, non-compliance, etc., and achieve low cost, simple steps, The effect of low pollution consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

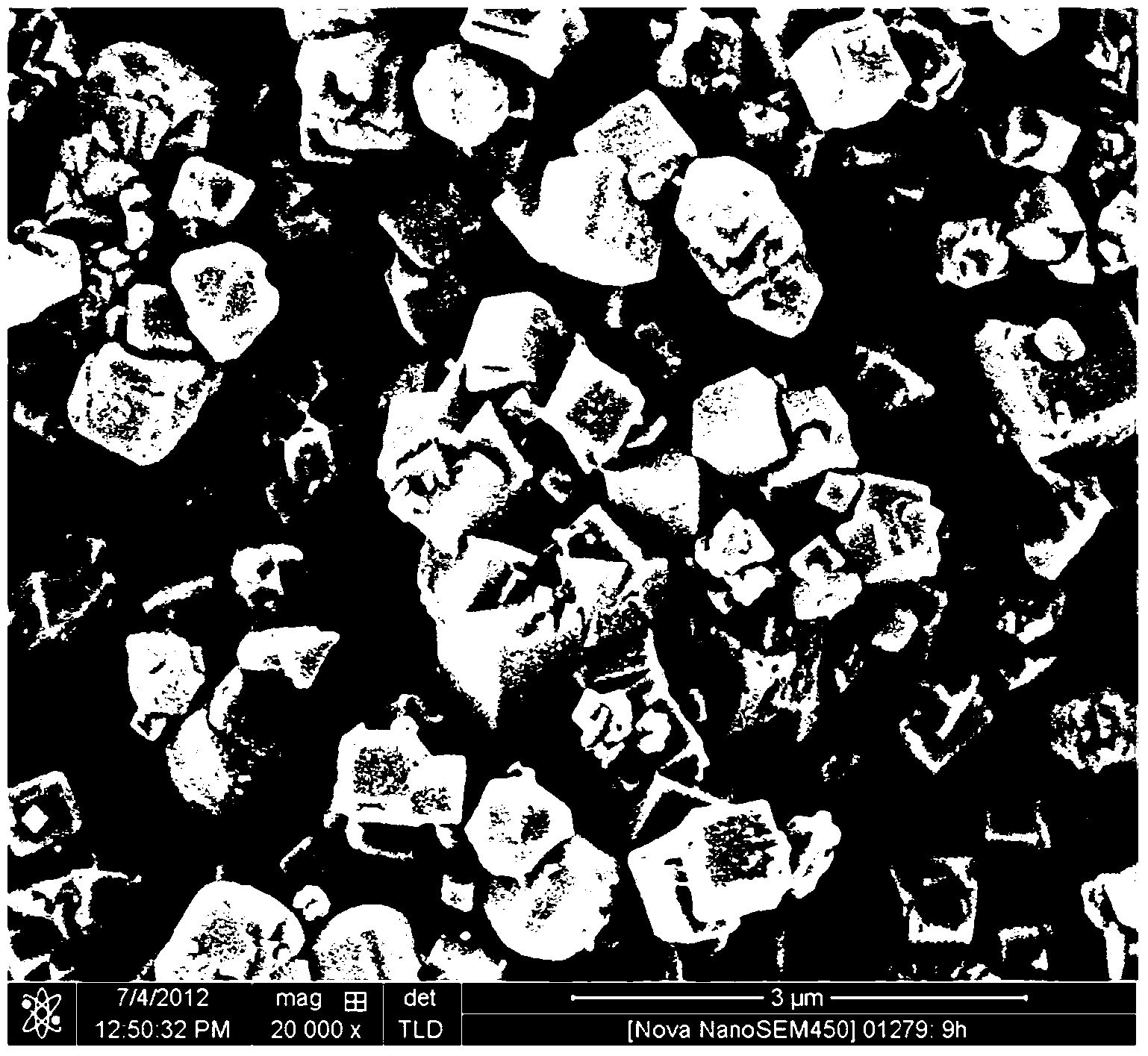

Image

Examples

Embodiment 1

[0029] This embodiment relates to a method for preparing a sodium alginate-xanthan gum modified nano-A zeolite assembly, the method comprising the following steps:

[0030] Step 1, use a pipette to pipette 4.5ml sodium alginate solution (mass percentage concentration is 2%), 1.5ml xanthan gum mixed solution (mass percentage concentration is 2%) and 4.5ml silica sol solution (mass percentage concentration is 2%) 10%) into a 50ml polytetrafluoroethylene container, stir evenly with a glass rod to make it completely mixed, and drop 15μl potassium borohydride solution (molar concentration is 4M) into it with a pipette to obtain the initial foaming solution;

[0031] Step 2: After the dense hydrogen bubbles are formed in the initial foaming solution, immediately drop 10ml of the foaming mother solution into 100ml of calcium chloride solution (0.2M molar concentration) with a rubber dropper, and wait for the foaming microspheres After forming, filter with a funnel to obtain the foame...

Embodiment 2

[0036] This embodiment relates to a method for preparing a sodium alginate-xanthan gum modified nano-A zeolite assembly, the method comprising the following steps:

[0037] Step 1, use a pipette to pipette 4.5ml (mass percentage concentration is 0.5%) sodium alginate solution and 4.5ml xanthan gum mixed solution (mass percentage concentration is 0.5%) and 4.5ml silica sol solution (mass percentage concentration is 0.5%) 30%) into a 50ml polytetrafluoroethylene container, stir evenly with a glass rod to make it completely mixed, add 4.5μl potassium borohydride solution (molar concentration is 1M) dropwise to it with a pipette, and obtain the foaming mother liquor;

[0038] Step 2: After the dense hydrogen bubbles in the foaming mother liquor are formed, immediately drop 10ml of the foaming mother liquor into 90ml of calcium chloride solution (0.2M molar concentration) with a rubber dropper, and wait for the foaming pellets to form Afterwards, the foamed microsphere matrix was o...

Embodiment 3

[0042] This embodiment relates to a method for preparing a sodium alginate-xanthan gum modified nano-A zeolite assembly, the method comprising the following steps:

[0043] Step 1, use a pipette to pipette 3.0ml sodium alginate solution (mass percentage concentration is 1%), 1.5ml xanthan gum mixed solution (mass percentage concentration is 1%) and 2.0ml silica sol solution (mass percentage concentration is 1%) 20%) into a 50ml polytetrafluoroethylene container, stir evenly with a glass rod to make it completely mixed, add 10μl of potassium borohydride solution (3M molar concentration) dropwise with a pipette to obtain a foaming mother solution;

[0044] Step 2: After the dense hydrogen bubbles in the foaming mother liquor are formed, immediately drop 10ml of the foaming mother liquor into 80ml of calcium chloride solution (0.2M molar concentration) with a rubber dropper, and wait until the foaming pellets are formed , filtered through a funnel to obtain the foamed microsphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com