Continuous production method of granular humic acid urea and activation reactor

A technology of humic acid urea and a production method, which is applied in the field of agricultural fertilizer production, can solve the problems that the nitrogen utilization efficiency in urea cannot be effectively improved, the best reaction effect of humic acid urea is affected, and it is not suitable for large-scale production and application, and the activation reaction is achieved. Short time, saving reaction time, the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

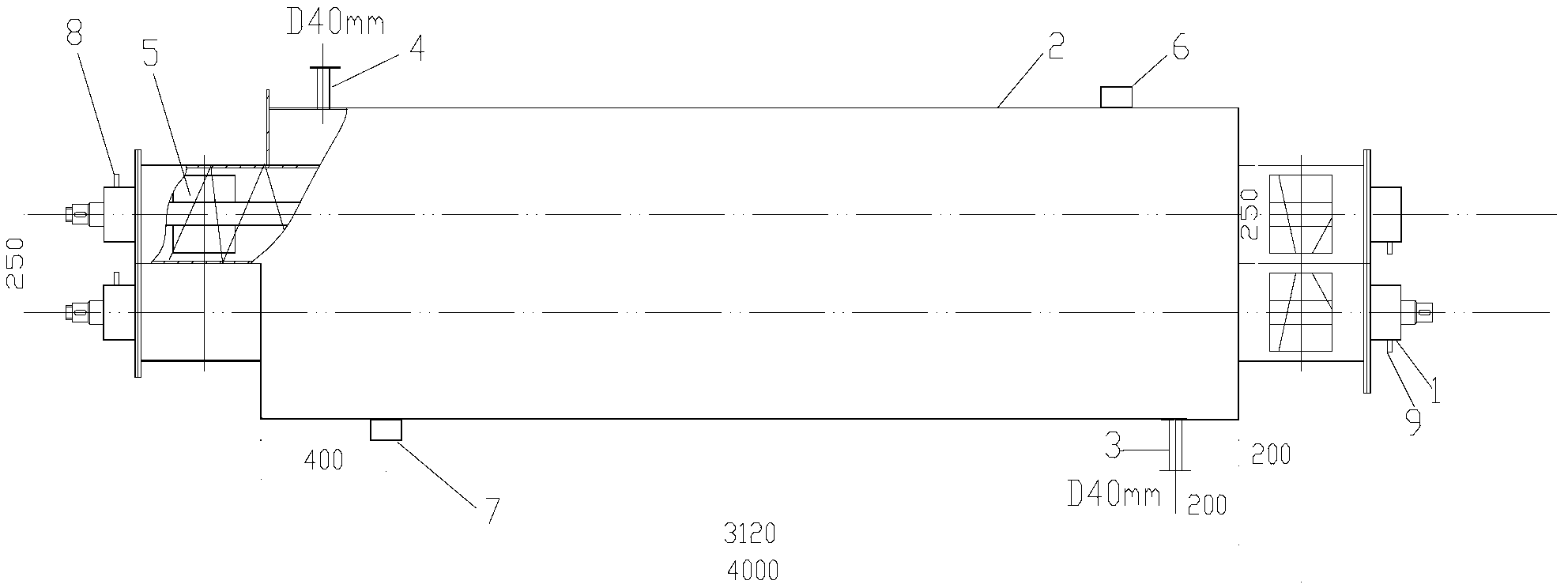

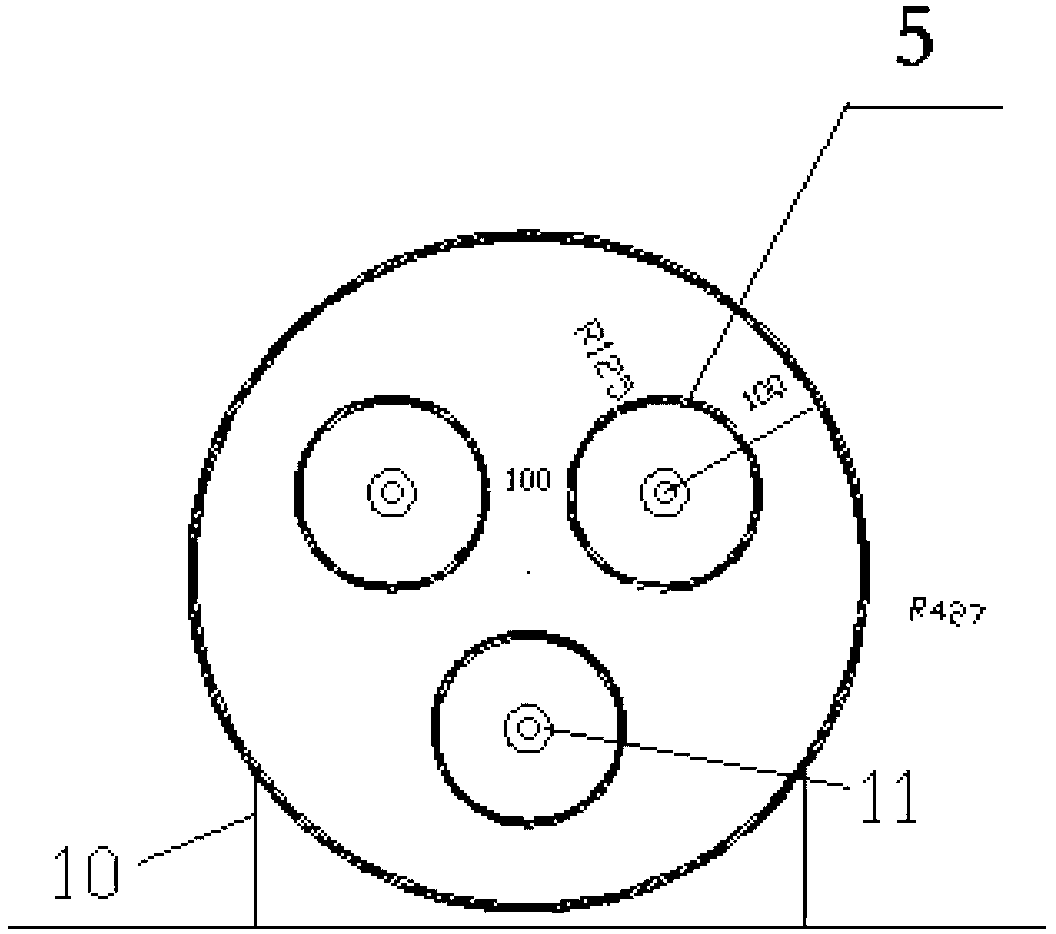

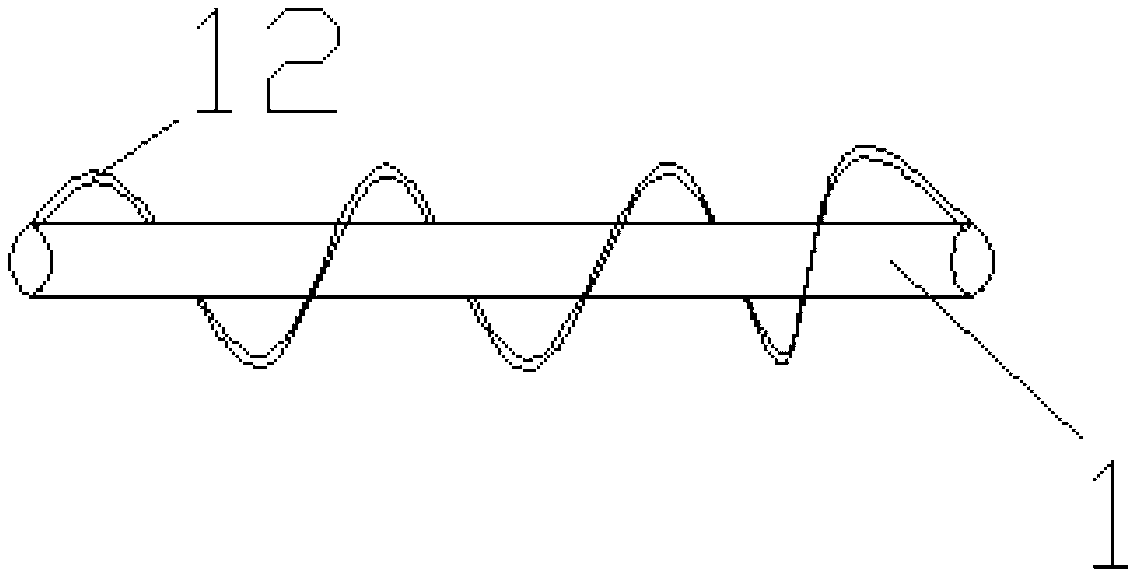

[0052] An activation reactor with a structure such as figure 1 , figure 2 , image 3 Shown, comprise airtight horizontal tank body and motor, airtight horizontal tank body is arranged on the base bracket 10, horizontal tank body comprises inner tank body and outer tank body 2, and the space between inner tank body and outer tank body The cavity is a heat transfer jacket, and the heat transfer jacket is filled with heat-conducting oil. On the side wall of the outer tank body 2, an oil inlet 3 and an oil outlet 4 are connected to the heat transfer jacket. On the side wall of the outer tank body 2 It is also provided with a feed port 6 and a discharge port 7 respectively connected to the inside of the inner tank body, and three stirring shafts 1 are arranged in the inner tank body. The stirring shaft 1 is driven by a motor, and the side wall of each stirring shaft 1 is There are two inner and outer layers, and the cavity between the inner and outer side walls is a heat transfe...

Embodiment 2

[0056] A kind of activation reactor, structure is shown in embodiment 1, difference is:

[0057] The feed port 6 is set on the upper part of the outer tank body 2, the discharge port 7 is set on the lower part of the outer tank body 2, the horizontal distance between the feed port 6 and the discharge port 7 is 4200 mm, and the oil inlet 3 is located at the lower part of the outer tank body 2 , the oil outlet 4 is located on the upper part of the outer tank body 2, and the horizontal distance between the oil inlet 3 and the oil outlet 4 is 4300mm.

[0058] The three stirring shafts 1 are arranged in an equilateral triangle in the inner tank, and the distance between two adjacent stirring shafts is 250mm. The diameter of the outer ring of the spiral blade is 260 mm. The minimum distance between the outer edge of the spiral blade on each stirring shaft and the inner tank is 120mm.

[0059] The airtight horizontal tank is 4500mm long, the inner diameter of the inner tank is 920m...

Embodiment 3

[0061] A continuous production method of granular humic acid urea, comprising using the activation reactor described in embodiment 1, the steps are as follows:

[0062] (1) Preparation of liquid catalyst

[0063] The raw materials are composed as follows in parts by weight: 20 parts of potassium hydroxide and 80 parts of water. Dissolve potassium hydroxide in water to prepare a potassium hydroxide solution.

[0064] (2) Preparation of mixed materials

[0065] Pulverize the lignite through a pulverizer, pass through a 150-mesh sieve, transport the sieved lignite, granular urea, and ammonium bicarbonate powder to a material mixer for full stirring and mixing, then spray potassium hydroxide solution, and immediately stir and mix evenly to obtain The mixed material is composed as follows in parts by weight: 33 parts of lignite, 57 parts of urea, 6 parts of ammonium bicarbonate powder, and 4 parts of potassium hydroxide solution.

[0066] (3) Turn on the activation reactor, pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com