Indoor practical straw mushroom medium and its preparation method

A culture medium and technology of straw mushrooms, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problems of unfavorable normal nutrition intake, different growth conditions of straw mushrooms, and less nutritional value and ingredients, so as to shorten the production time and Growth time, convenience of nutrient absorption, effects of increasing inorganic nitrogen sources and inorganic salt ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: A practical medium for straw mushrooms indoors, the formula and weight ratio of the medium are as follows: 15%-20% rice straw, 30%-35% peanut shells, 23%-28% dried chicken manure, 3 %-5% plant ash, 2%-4% gypsum, 0.1%-0.3% ammonium sulfate, 0.2%-0.4% potassium dihydrogen phosphate, 0.1%-0.2% cellulase.

[0027] The rice straw described in the present invention is the straw straw obtained after being placed in a fermentation tank for fermentation treatment and dried in the sun. The length range of the rice straw particles is 1-2 cm, and the rice straw not only provides a carbon source for the growth of straw mushrooms , and it is easy to attach and form other substances, and has good practical effect. The peanut shells of the present invention are the original shells obtained after ordinary peanuts are degranulated, and are stirred by a crushing mixer. The peanut shells are solid particles with a surface diameter of 0.6-1 cm after stirring and crushing, and th...

Embodiment 2

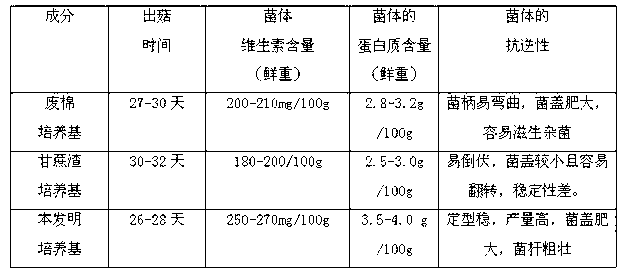

[0029] Example 2: The results of comparative tests under the same environment on straw mushroom medium prepared from cotton waste and bagasse commonly used in the market as the main raw materials are shown in the table below:

[0030]The preferred weight percentage distribution of various components of the straw mushroom culture medium of the present invention is as follows: 20% of rice straw, 30% of peanut shell, 25% of dried chicken manure, 4% of plant ash, 4% of gypsum, 0.2% of ammonium sulfate, diphosphate Potassium hydrogen 0.2%, cellulase 0.15%; the mass percentage ratio of the distilled water used in the configuration medium is 119.4%.

[0031]

[0032] According to the comparison experiment between the culture medium formulated according to this ratio and the common culture medium, as shown below, the culture medium of the present invention is not only shorter than other common culture mediums in the fruiting time, but also the vitamin content and protein content o...

Embodiment 3

[0033] Example 3: The configuration method of a kind of indoor practical straw mushroom culture medium of the present invention:

[0034] 1) Put the ordinary rice straws into the ordinary fermentation tank after being grouped and bundled for fermentation. The fermentation time is 10 hours. The water content is 5%-8%. The rice straw is stirred and crushed by a pulverizer. The length of the crushed straw is 1-2cm, and it is weighed for use;

[0035] 2) Peanut raw shells obtained by removing grains from ordinary peanuts. After the raw peanut shells are washed and soaked for 24 hours, the stains on the initial raw shells and the washed peanut raw shells are dried at a temperature of 60-70°C. Machine drying treatment, the dried peanut shells are stirred and pulverized by a pulverizer, and then screened through a filter screen with an aperture of 0.6 cm and a screen structure with an aperture of 1 cm to obtain solid particles of 0.6-1 cm;

[0036] 3) Concentrate the excrement of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Surface diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com