Method for preparing amidated pectin with pericarp serving as raw material

A technology of amidated pectin and amidation reaction, which is applied in the field of amidated pectin preparation and amidated pectin product preparation, can solve the problem of low yield of amidated pectin, low gel strength, pectin molecular Short chain and other problems, to achieve the effect of promoting wound healing, low dosage, and not easy to dehydrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

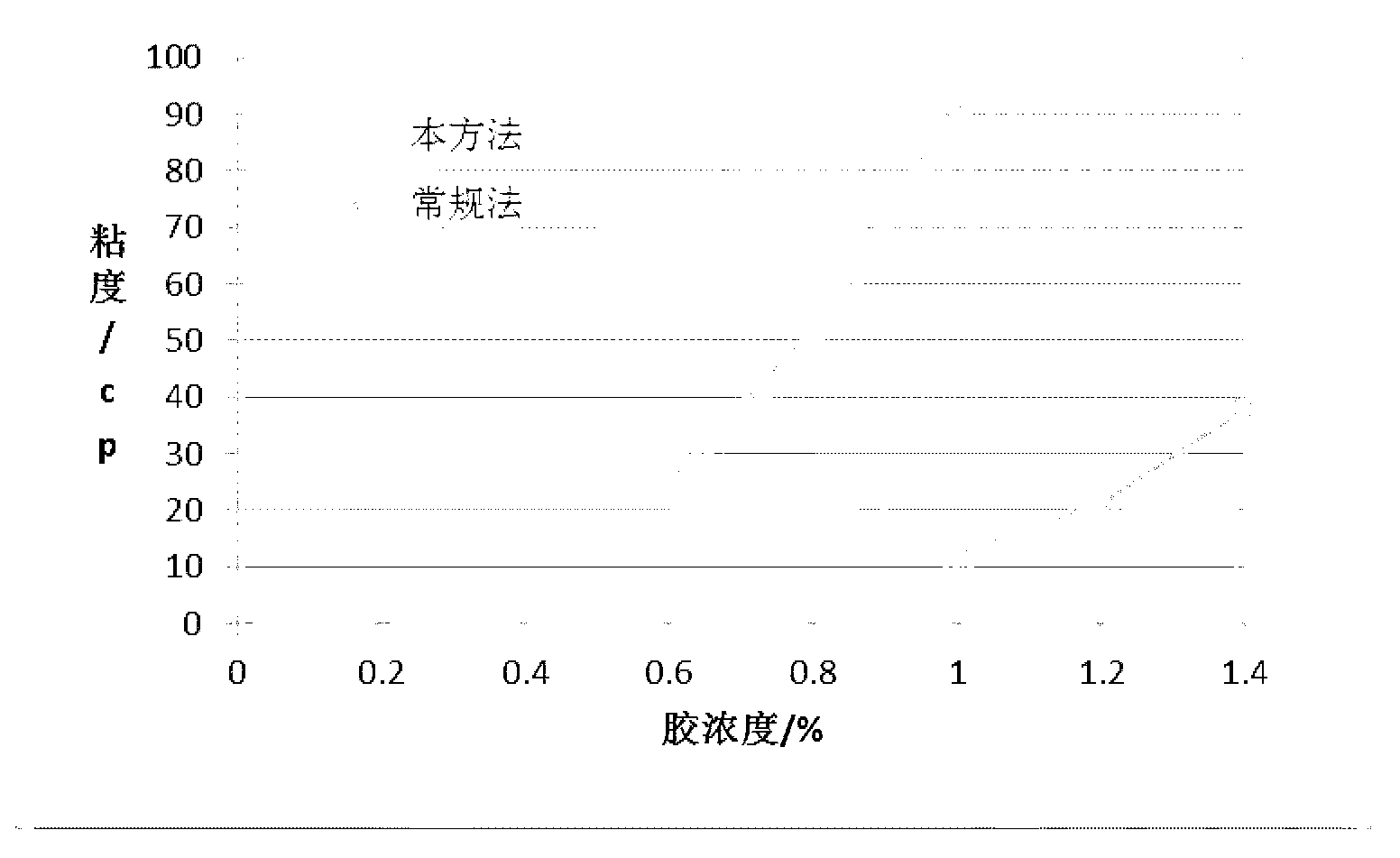

Method used

Image

Examples

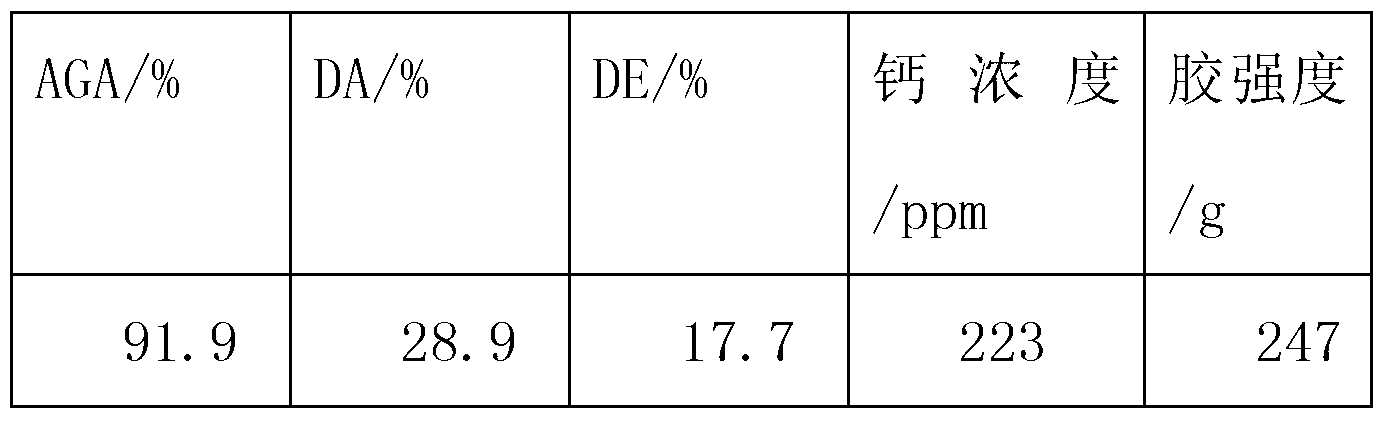

Embodiment 1

[0058] Take 100g of dried citrus peel with a water content of 11% (DE=70%, AGA=44%), the particle size of the citrus peel is 3mm~5mm, put it in 1000ml of aqueous solution, the water temperature is 26°C, add 15g of sodium chloride, dihydrate Calcium chloride 6.3g, magnesium chloride 2.1g.

[0059] After stirring for about 20 minutes, the citrus peel becomes soft. Heat the solution to 45° C., add sodium carbonate to adjust the pH to 7.5, add 0.22 g of pectin esterase, and stir for 40 minutes.

[0060] Adjust the pH to 5.5 with nitric acid again, add 23.5g of urea after the pH value is stable, pay attention to ventilation, and raise the temperature to 60°C at the same time, stop stirring after about 1 hour.

[0061] Immediately squeeze the suspension mixture dry, leaving residue. Add 1000ml of deionized water to the slag, adjust the pH value of the suspension to 1.3 with nitric acid, stir for 10-20 minutes, and squeeze dry again.

[0062] Repeat 2 times until the pH value in th...

Embodiment 2~5

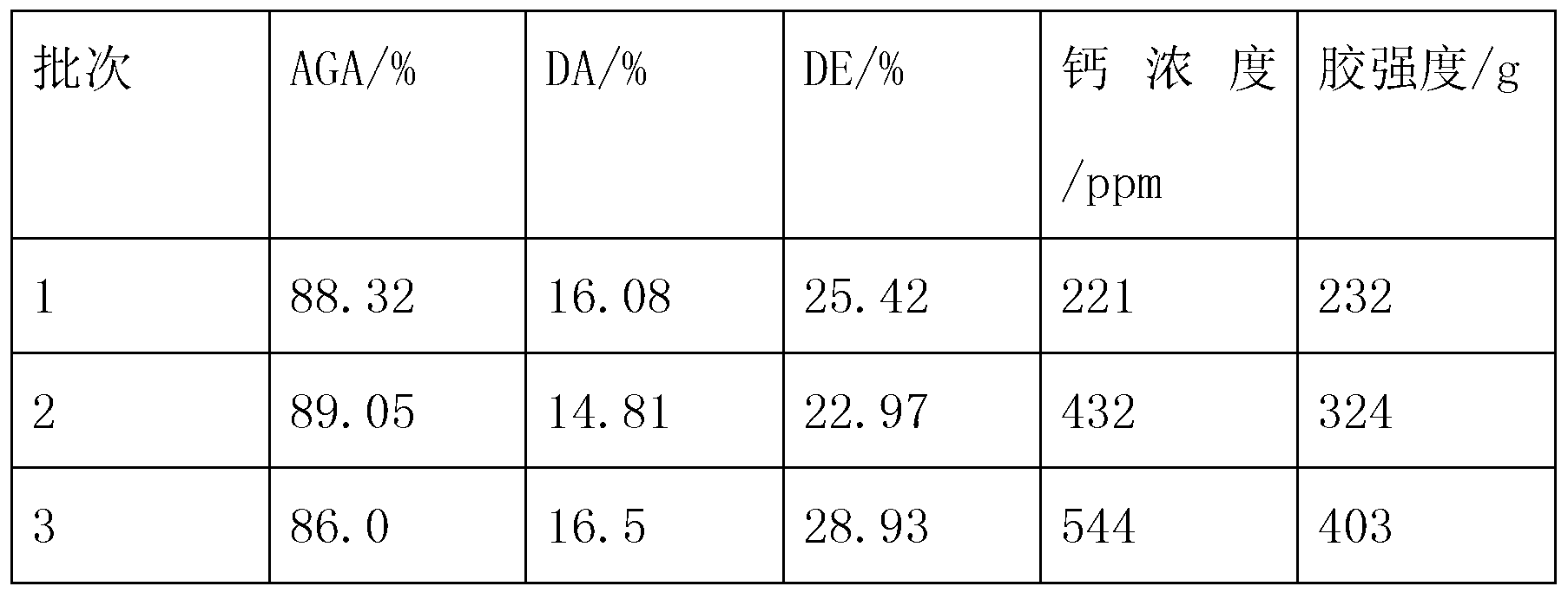

[0070] In Examples 2 to 5, after the lemon peel was deenzyme-washed, it was cut into small pieces of 5 mm with a dicing machine, dried, and the water content was 10.8%. The measured AGA content of the lemon peel is 42.6%, and the DE value is 70.3%. Take 100g and process it according to Example 1. Compared with Example 1, except that the amidation time was changed, other parameters remained unchanged.

[0071] According to the method for separating the pectin product described in Example 1, the performance parameters of the measured pectin are shown in Table 2.

[0072] Table 2:

[0073] time

[0074] 10 minutes

Embodiment 6

[0076] In Example 6, scrape off the outer oil bubble layer from the pomelo peel, cut it into small pieces of 5mm with a dicing machine, wash off the enzyme, and then dry it. The moisture content is 8.2%. The AGA content of the pomelo peel was measured to be 54.4%, and the DE value was 73.5%. 100 g was taken and processed according to Example 1. Repeat 3 times.

[0077] According to the method for separating the pectin product described in Example 1, the performance parameters of the measured pectin are shown in Table 2.

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com