Agarose-based dimethylpropiothetin acrylate grafted polymer and preparation method therefor

A technology of agarose-based thiobetaine and graft polymer, which is applied in the field of agarose-based thiobetaine acrylate graft polymer and its preparation, and can solve the problem that molecular weight and molecular weight distribution control cannot be realized, mixed homogeneous phase Polymer and other problems, to achieve the effect of adjustable graft length, mild and easily controllable reaction conditions, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

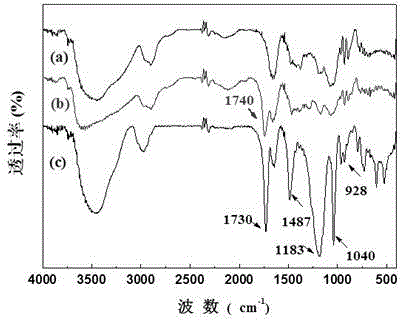

[0024] 1) Measure 50 mL of anhydrous N, N-dimethylformamide into a 250 mL three-necked bottle, and weigh 1 g

[0025] Agarose was added to it, heated to 90°C, and mechanically stirred for 4 h to completely dissolve the agarose. Cool to room temperature, add 0.066 g of 4-lutidine to activate the hydroxymethyl group of agarose, and react for 1 h. After completion, the system was placed in an ice-water mixture.

[0026] 2) Measure 2mL of triethylamine and add it to the above agarose solution. Measure 0.75 mL bromo-isobutyryl

[0027] Bromine was dissolved in 30 mL of anhydrous N,N-dimethylformamide solution, and then added dropwise to the agarose solution at a rate of one drop every 5 seconds. After reacting for 24 hours, the reaction solution was added dropwise into 200 mL of ethanol. The obtained precipitate was washed with deionized water, centrifuged, and vacuum-dried for 12 hours to obtain a white agarose-based initiator.

[0028] 3) Weigh 0.1 g of the above white powde...

example 2

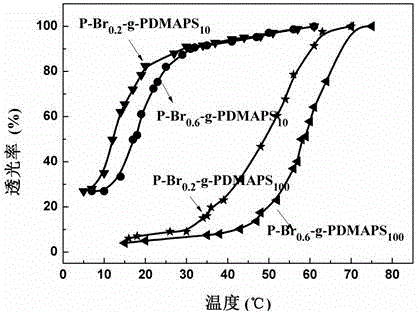

[0031] The steps of this example are basically the same as those of Example 1, except that the monomer thiobetaine acrylate in step 3) in Example 1 is changed from 4.23g to 0.423g; correspondingly, step 3) in Example 1 is changed The amount of dimethyl sulfoxide solution in the solution was changed from 100 mL to 10 mL. Obtain white powdery agarose-based thiobetaine grafted polymer P-Br 0.6 -g-PDMAPS 10 . The UCST of this polymer is 17°C.

example 3

[0033]The steps of this example are basically the same as those of Experiment 1, except that: the bromine-isobutyryl bromide in step 2) in Example 1 is changed from 0.75mL to 0.25mL; the monomeric sulfur in step 3) in Example 1 Substitute betaine acrylate was changed from 4.23g to 1.66g. Obtain white powdery agarose-based thiobetaine grafted polymer P-Br 0.2 -g-PDMAPS 100 . The UCST of this polymer was 49°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com