Sorting technique for valuable elements associated with gold

A sorting technology for valuable elements, applied in the field of mineral processing, can solve problems such as complicated process improvement, increased energy consumption of grinding, and hazards of flotation, and achieves the effects of simple operation process, improved extraction rate, and no pollution and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

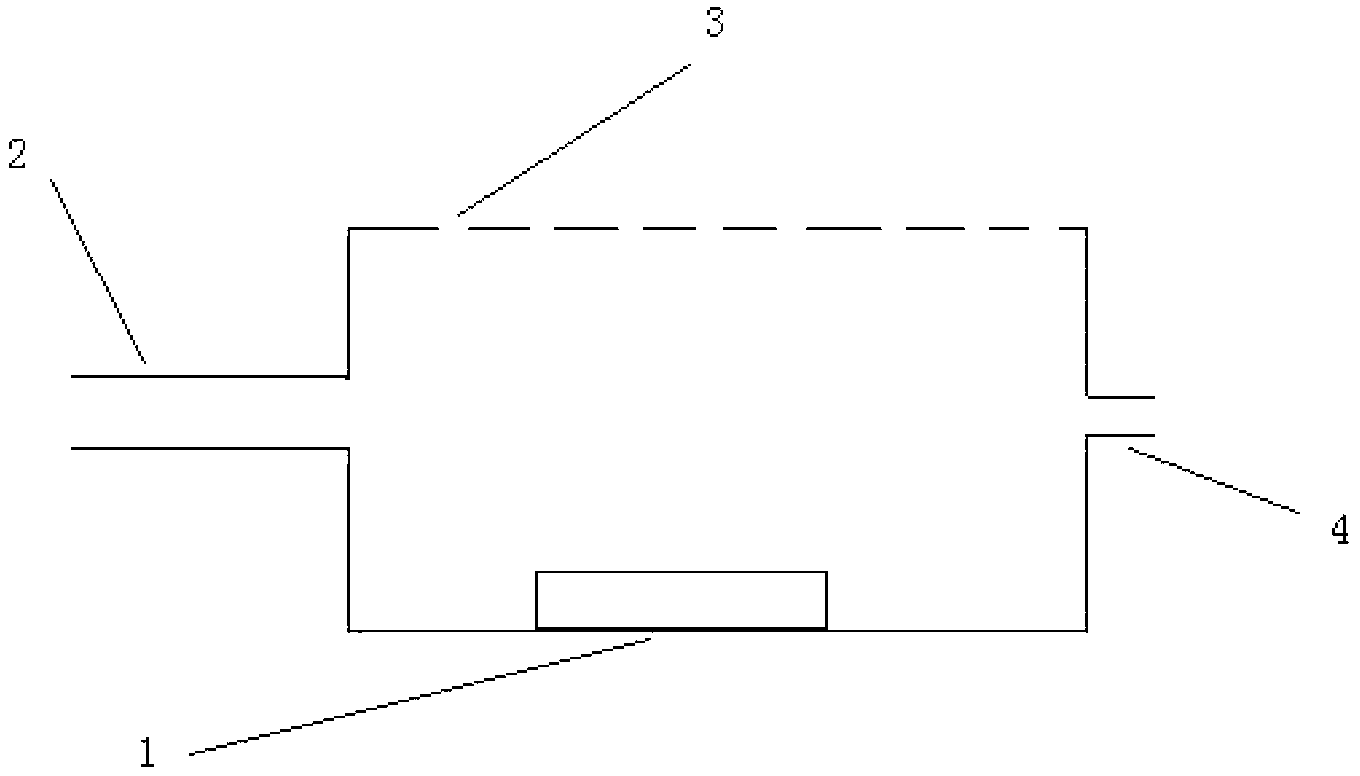

Image

Examples

Embodiment 1

[0039] A process for sorting valuable elements of associated gold, comprising the steps of:

[0040] 1) Preparation of composite bacterial solution: The composite bacterial solution is prepared by mixing the following raw material bacteria, including 25% of Rhodococcus, 20% of acidophilic Thiobacillus ferrooxidans, 15% of Nitrosomus, and 15% of Bacillus cereus %, Alcaligenes faecalis 10%, Aspergillus niger 10%, Thiobacillus denitrification 5%; the concentration of each raw material bacteria is 2.0×10 8 a / ml;

[0041] 2) Desulfurization, decarbonization and phosphorus removal: crush the gold-bearing iron ore through a crusher, then send it to a ball mill, grind it to a particle size of 100 mesh ore powder, then mix the ore powder with limestone above 100 mesh, and stir evenly to obtain The mixture 1 is then sent to the bioreactor through the feed port, the upper nozzle hole of the bioreactor sprays the composite bacterial liquid, and the mixture 1 is desulfurized, decarbonized...

Embodiment 2

[0050] Verification of the effect of bacterial fertilizer:

[0051] The bacterial fertilizer prepared by the embodiment of the present invention 1 is used to process the polluted soil near a coking factory. After testing, the content of sulfide in the soil is 870g / m3, the content of aromatic hydrocarbons is 430g / m3, and ammonia nitrogen is 104g / m3; Treatment process: First, loosen the soil and level off, spray water to keep the soil water content at 30%, and then spread the bacterial fertilizer according to the amount of 1kg of bacterial fertilizer per cubic meter of soil. After one week, detect the content of various pollutants, among which , the content of sulfide is 16g / m3, the content of aromatic hydrocarbon is 21g / m3, and the content of ammonia nitrogen is 3g / m3. It can be seen that the bacterial fertilizer of the present invention can be used to control polluted soil and has a good application prospect.

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com