Low-pollution energy conservation slag system used for manufacturing hollow ingot by remelting electroslag in ingot drawing way

A technology of electroslag remelting and hollow ingot, which is applied in the field of pre-melted slag, can solve the problems of ingot-pulling electroslag remelting, poor high-temperature toughness, easy slag leakage or steel leakage, etc., and achieve good removal of inclusions ability, high temperature plasticity, and the effect of reducing slag leakage and steel breakout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

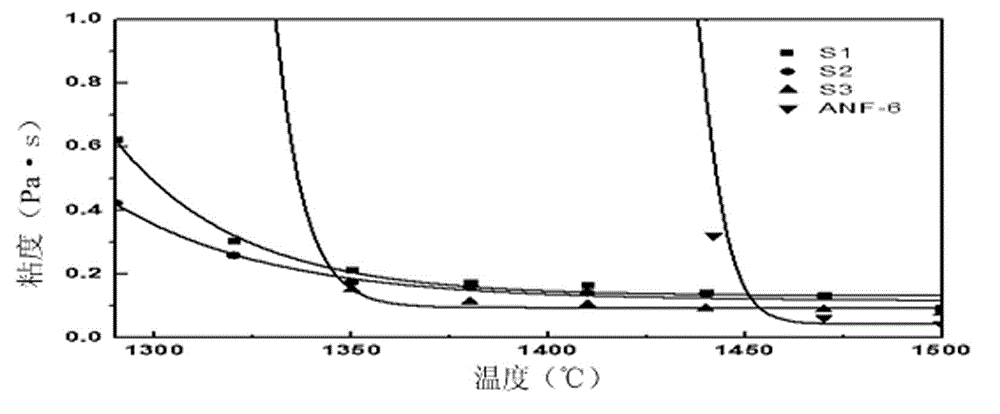

Embodiment 1

[0027] Using fluorite, lime, industrial alumina, fused magnesia, silica and sodium carbonate as raw materials, the prepared raw materials are mixed and melted in a three-phase electric arc furnace. Refined for 30 minutes; then cast into a cast iron pan with a bottom thickness of 100mm, and then cooled and solidified to room temperature for 4 hours, crushed by a crusher and screened out the part with a particle size of 1~10mm to obtain the electroslag used for ingot extraction The low-polluting and energy-saving pre-melting slag of hollow ingots is remelted and packaged into a 20kg bag, which is used for power supply to a slag furnace; the composition of the above-mentioned pre-melting slag is Al by weight percentage. 2 O 3 15%, CaO37%, SiO 2 14%, MgO1%, Na 2 O3%, the balance is CaF 2 and inevitable impurities; binary basicity CaO / SiO 2 is 2.64, the melting temperature is 1250~1270℃, and the resistivity at 1600℃ is 0.512Ω·cm; the temperature-viscosity curve is as follows f...

Embodiment 2

[0032] Using fluorite, lime, industrial alumina, fused magnesia and silica as raw materials, the prepared raw materials are mixed and then melted in a three-phase electric arc furnace. ; Then cast into a cast iron pan with a bottom thickness of 100mm, and then cooled and solidified to room temperature for 4.5 hours, crushed by a crusher and screened out the part with a particle size of 1~10mm, and obtained for ingot-drawing electroslag remelting. Take the low-polluting and energy-saving pre-melting slag of the hollow ingot, package it into a 20kg bag, and use it to power the slag furnace; the composition of the above-mentioned pre-melting slag is Al by weight percentage 2 O 3 20%, CaO35%, SiO 2 10%, MgO3%, the balance is CaF 2 and inevitable impurities; binary basicity CaO / SiO 2 is 3.5, the melting temperature is 1270~1280℃, and the resistivity at 1600℃ is 0.569Ω·cm; the temperature-viscosity curve is as follows figure 1 It can be seen from the figure that when the tempera...

Embodiment 3

[0036] Using fluorite, lime, industrial alumina, fused magnesia and silica as raw materials to prepare low-polluting and energy-saving pre-melting slag for producing hollow ingots by ingot-drawing electroslag remelting, the method is the same as that in Example 2, and its components are Weight percent is Al 2 O 3 19%, CaO36%, SiO 2 12%, MgO3%, the balance is CaF 2 and inevitable impurities; binary basicity CaO / SiO 2 is 3, the melting temperature is 1260~1280℃, and the resistivity at 1600℃ is 0.603Ω·cm;

[0037] Adopt the above-mentioned pre-melted slag electroslag remelting steel P91 for high pressure boiler, the method is the same as that of embodiment 1, the difference is:

[0038] During electroslag remelting, the amount of pre-melting slag is 300~350kg / furnace steel, the voltage is 72~76V, the current is 20~22kA, and the melting rate is 1000~1100kg / h. The control of the melting furnace used is when extracting hollow ingots The pulling speed of the hollow ingot is 5~6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com