EC-type electrochromism laminated glass and intelligent dimming system based on same

一种夹胶玻璃、电致变色的技术,应用在光学、遮光屏、非线性光学等方向,能够解决107726.2、201010143516.3、201010171953.6、201010219433.8、201020647387.7、201080015114.3、201120170431.4、200580010097.3、201120362381.X、201120384949.8、201120390966.2 .

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

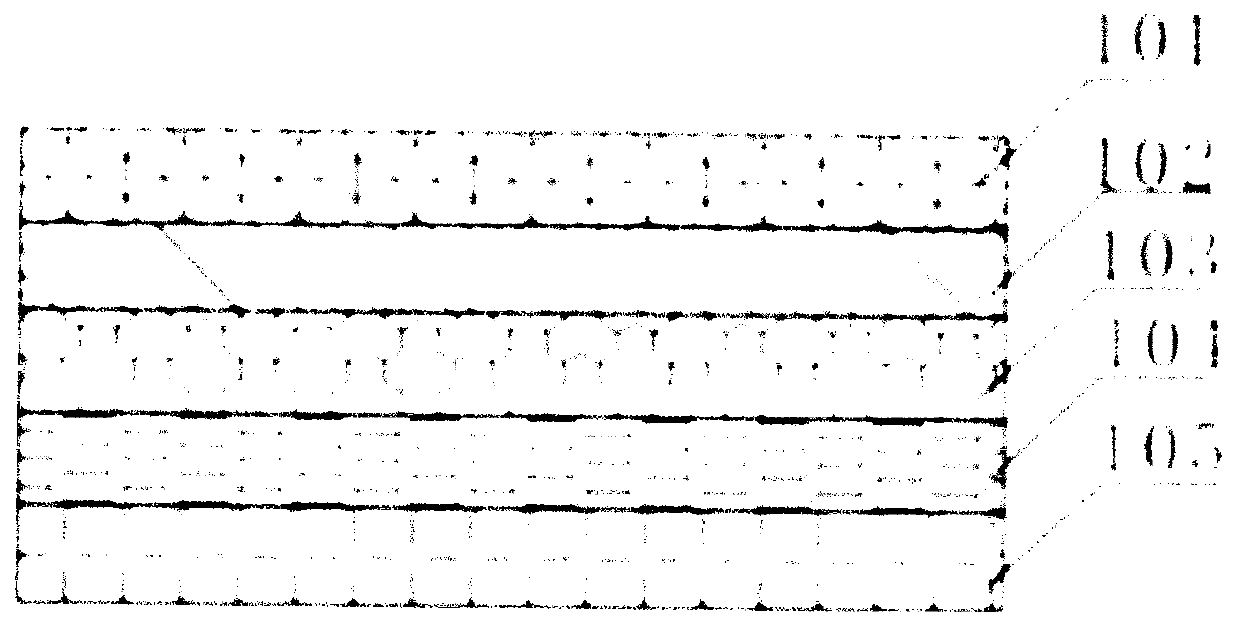

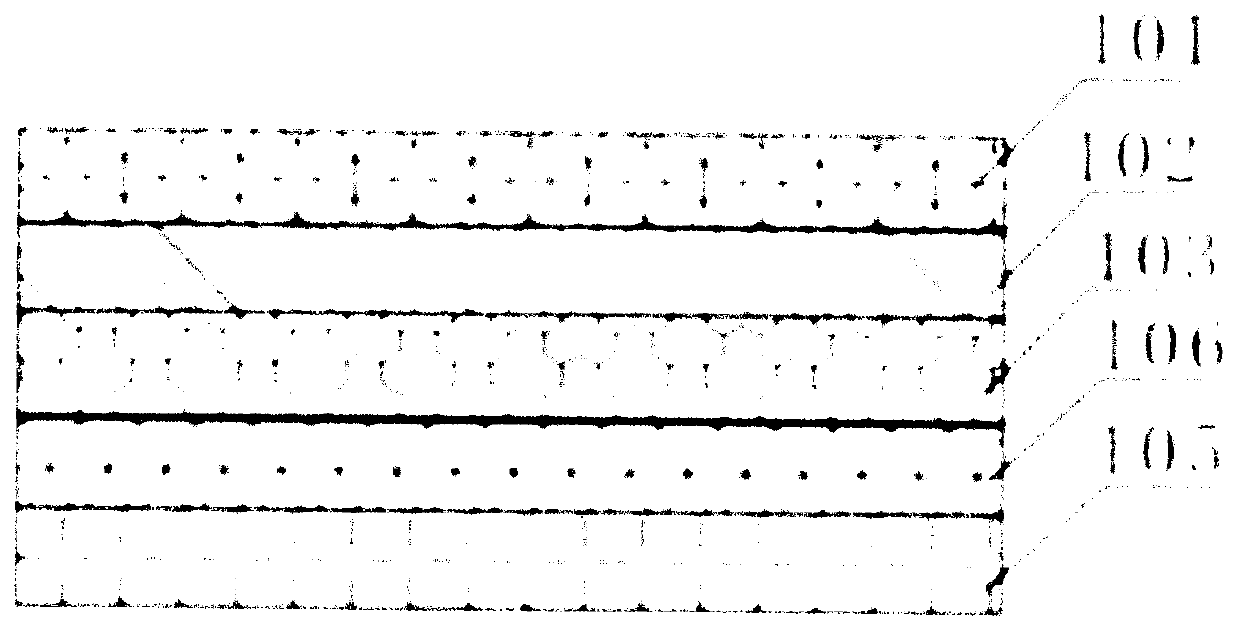

[0035] (1). Prepare the first conductive glass 101 . In an area of 300×300cm 2 Clean the conductive surface of the commercial FTO inorganic glass, and evenly coat 100 ml of the commercial ITO nanoparticle aqueous dispersion with a concentration of 20%. After natural drying, bake at 100°C for about 1 hour, and the ITO nanoparticles are uniformly deposited on the FTO conductive glass. surface and form a conductivity enhancing film with a thickness of about 1000 nm to obtain an ITO / FTO conductive glass as the first conductive glass in this embodiment.

[0036] (2). Depositing the first electrochromic film layer 102 . The above-mentioned first conductive glass and a commercial tungsten oxide ceramic target were respectively fixed in the radio frequency sputtering apparatus, and the chamber was evacuated by a vacuum pump and a molecular pump, and then radio frequency sputtering was carried out under an argon atmosphere to obtain a thickness of about 500nm WO 3 film, that is, t...

Embodiment 2

[0044] (1). Prepare the first conductive glass 101 . Make a piece with an area of 300×300cm 2 The commercial ITO / PMMA organic conductive glass, after the surface is cleaned and dried, is directly used as the first conductive glass in this embodiment.

[0045] (2). Depositing the first electrochromic film layer 102 . Fix the above-mentioned first conductive glass and a commercial tungsten oxide-titanium oxide mixed ceramic target in the magnetron sputtering apparatus respectively, use a vacuum pump and a molecular pump to evacuate the cavity, and then perform magnetron sputtering under an argon atmosphere , a WO with a thickness of about 400 nm was prepared 3 -TiO 2 film, that is, the first electrochromic film layer is deposited on the first conductive glass.

[0046] (3). Prepare the ion-conducting electrolyte film 103 . With the commercial EVA powder of 100 weight parts, the polyethylene glycol PEG plasticizer of 30 weight parts as the raw material of manufacturing com...

Embodiment 3

[0053] (1). Prepare the first conductive glass 101 . In an area of 300×300cm 2 Clean the conductive surface of the commercial ITO conductive glass, and evenly coat 100 ml of the commercial ITO nanoparticle dispersion with a concentration of 20%. After natural drying, bake it at about 100°C for about 1 hour to obtain the ITO / ITO conductive glass, and then Put the conductive glass as a working electrode into an electrodeposition cell equipped with an appropriate amount of 0.1M aniline aqueous solution, ultrasonically for 5 minutes to make the aniline solution soak into the ITO nanoparticle layer, a commercial saturated calomel electrode as a reference electrode, and a piece of commercial platinum The electrode was used as a counter electrode, and was deposited at a constant potential of 0.85V for 5 minutes to prepare a polyaniline-ITO mixed conductivity-enhancing film with a thickness of about 1000 nanometers, which was used as the first conductive glass in this embodiment.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com