Preparation method of agricultural organic fertilizer by treating pure straws as raw material

A technology of organic fertilizer and straw, applied in the field of organic fertilizer and its preparation, can solve the problems of soil beneficial microorganism deficiency, endangering human living environment, low density of straw powder, etc., to reduce soil-borne diseases, increase emergence rate, and enhance photosynthesis The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

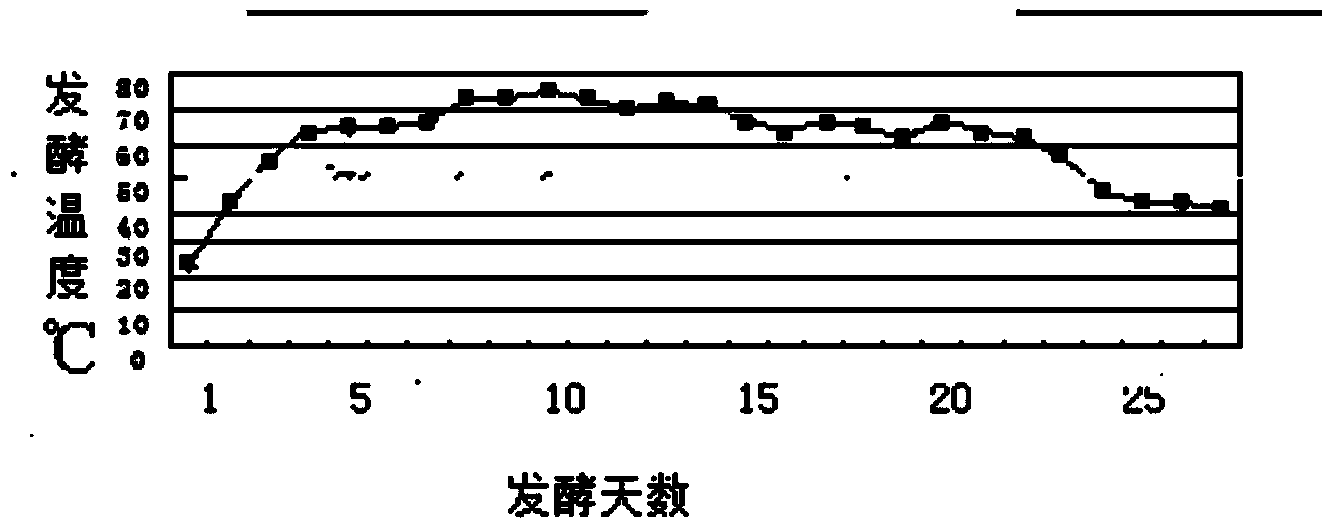

Embodiment 1

[0024] The preparation method of agricultural organic fertilizer using pure straw as raw material includes the following steps:

[0025] (1) Screening, separating, purifying, rejuvenating and cultivating Nocardia spp., Bacillus megaterium, Lactobacillus plantarum, Bacillus stearothermophilus, and Trichoderma viride respectively, and then inoculate various bacteria into industrial fermentation tanks. Fermentation. The fermentation conditions are: Nocardia groovens, Bacillus megaterium, and Lactobacillus plantarum. The medium composition is 0.5% yeast extract, 0.5% peptone, 5% brown sugar, 0.1% Tween-80, 0.05% sodium chloride, 0.05% Dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% calcium carbonate, medium temperature 35°C, culture time 24 hours. The composition of Bacillus stearothermophilus licheniformis is 0.5% yeast extract, 0.5% peptone, 5% brown sugar, 0.1% Tween-80, 0.05% sodium chloride, 0.05% dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% Ca...

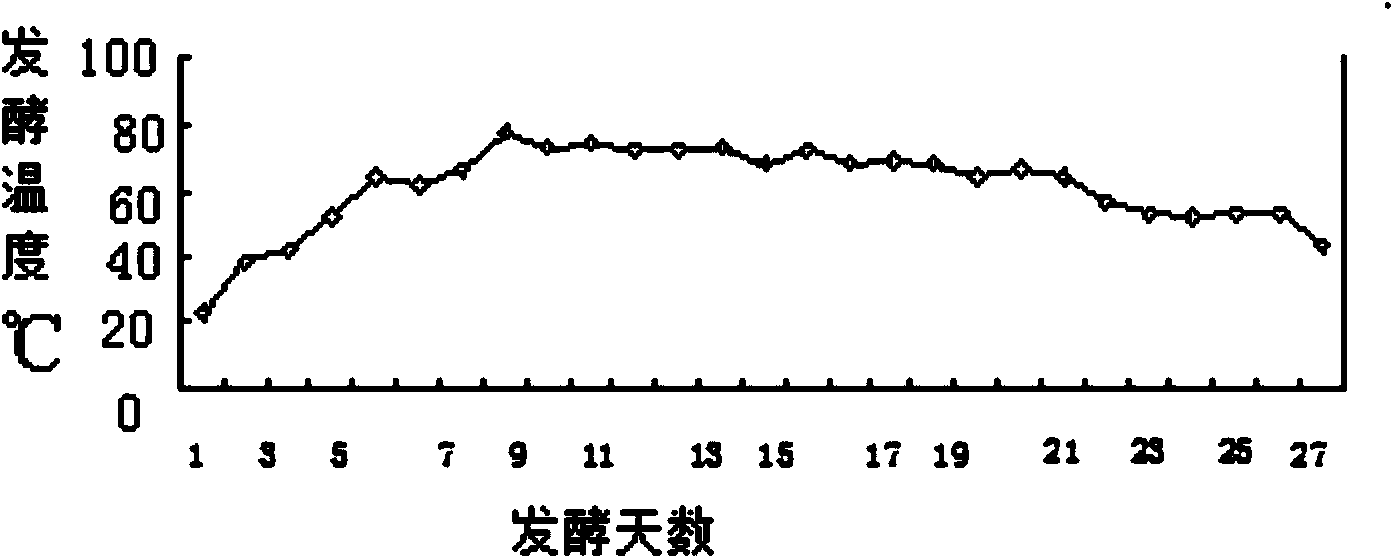

Embodiment 2

[0034] The preparation method of agricultural organic fertilizer using pure straw as raw material includes the following steps:

[0035] (1) Screening, separating, purifying, rejuvenating and cultivating Nocardia, Bacillus megaterium, Lactobacillus plantarum, Bacillus stearothermophilus, and Trichoderma viride respectively, and then inoculate various bacteria into industrial fermenters. After fermentation. The fermentation conditions are: Nocardia groovens, Bacillus megaterium, and Lactobacillus plantarum. The medium composition is 0.5% yeast extract, 0.5% peptone, 5% brown sugar, 0.1% Tween-80, 0.05% sodium chloride, 0.05% Dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% calcium carbonate; culture medium temperature is 25℃, culture time is 36 hours; Bacillus stearothermophilus licheniformis culture medium composition is 0.5% yeast extract, 0.5% peptone, 5% brown sugar , 0.1% Tween-80, 0.05% sodium chloride, 0.05% dipotassium hydrogen phosphate, 0.05% magnesium sul...

Embodiment 3

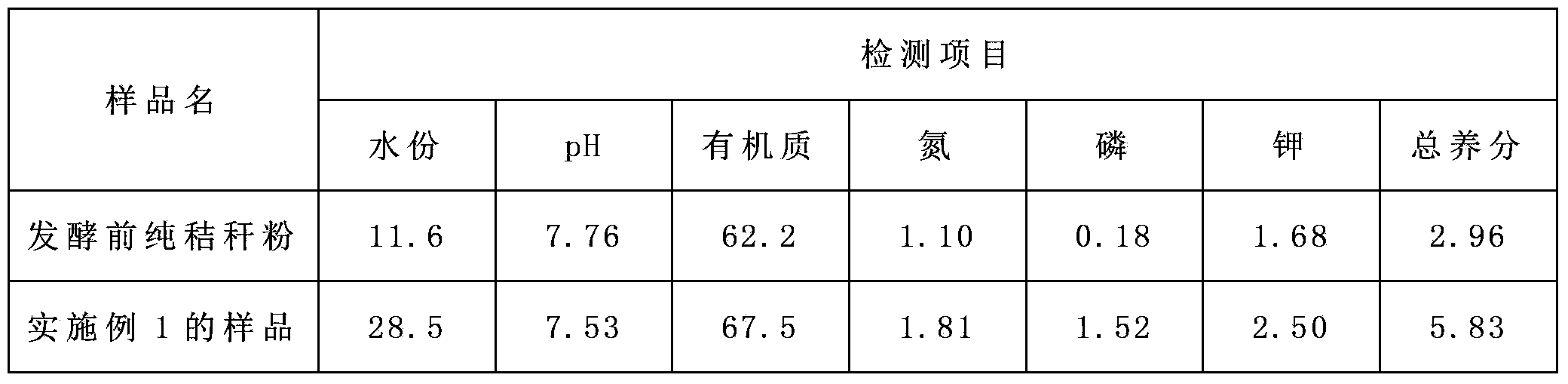

[0042] Example 3 Fertilizer effect test

[0043] Test time: September 3, 2012 to September 24, 2012. The test site is located in Hua'an Farm, Gushan Village, Pingwang Town, Wujiang City; the tested soil is black mixed soil, pH 7.5, organic matter 32.1g / kg, total nitrogen 1.23g / kg, available phosphorus 12.2mg / kg, available potassium 125mg / kg. The test fertilizer was the pure straw organic fertilizer obtained in Example 1, the test crop was Chinese cabbage, and the variety was Huaguan Qinggeng vegetable.

[0044] Experimental group settings:

[0045] Experimental group 1: Blank control group. No fertilizer is applied, and the yield is the basic fertility yield;

[0046] Experimental group 2: Conventional fertilizer control group. Converted into chemical fertilizer application according to local conventional fertilizer application, no other fertilizers are applied. The dosage is compound fertilizer with total nutrients ≥ 45%, 50kg / mu;

[0047] Experimental group 3: The experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com