Ultraviolet or near ultraviolet inspired LED fluorescent powder and preparation method thereof

A phosphor and tungstate technology, which is applied in the field of ultraviolet or near-ultraviolet excited LED phosphor and its preparation, can solve the problems of less research on doping, and achieve the effects of simple preparation process, easy control of conditions, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

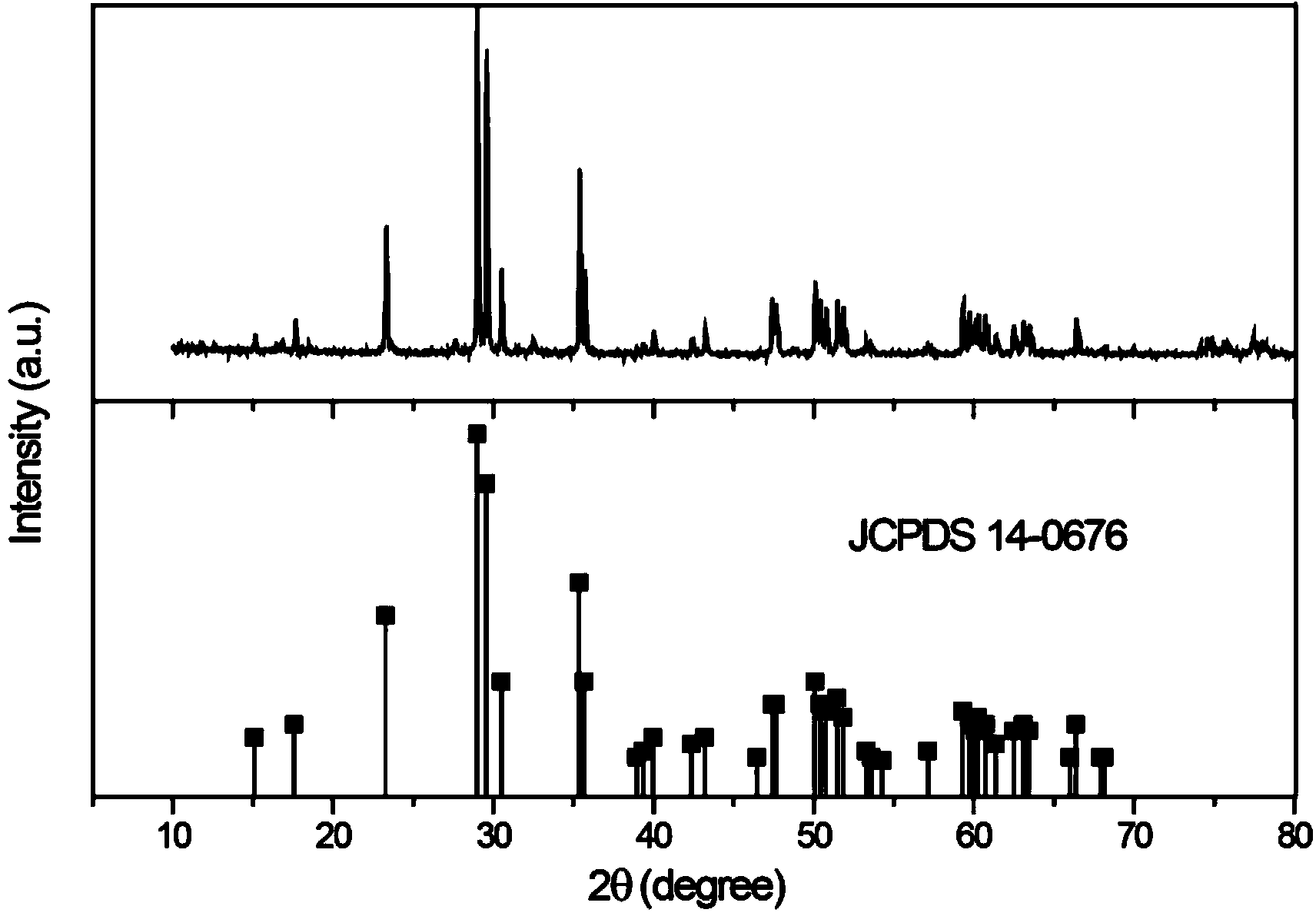

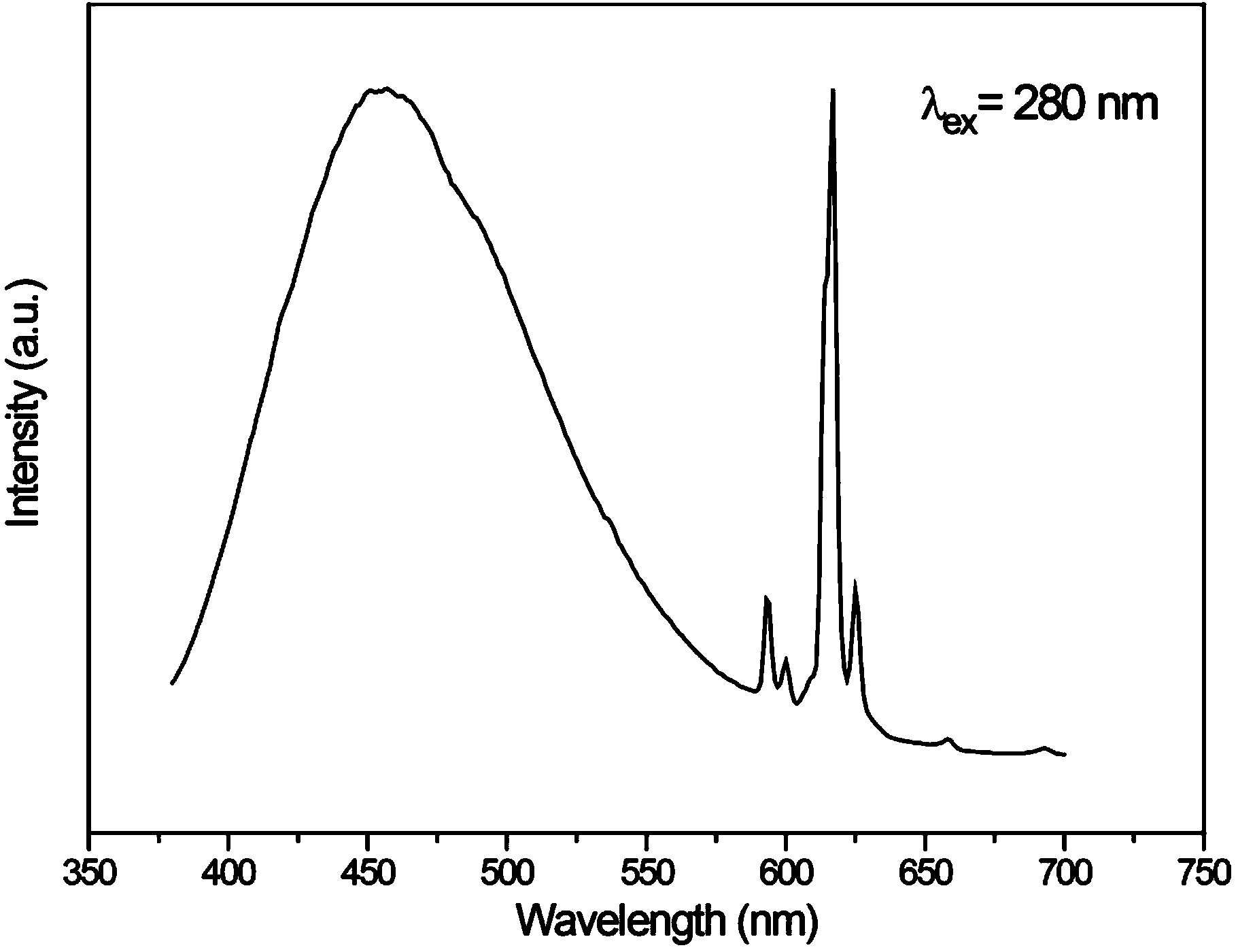

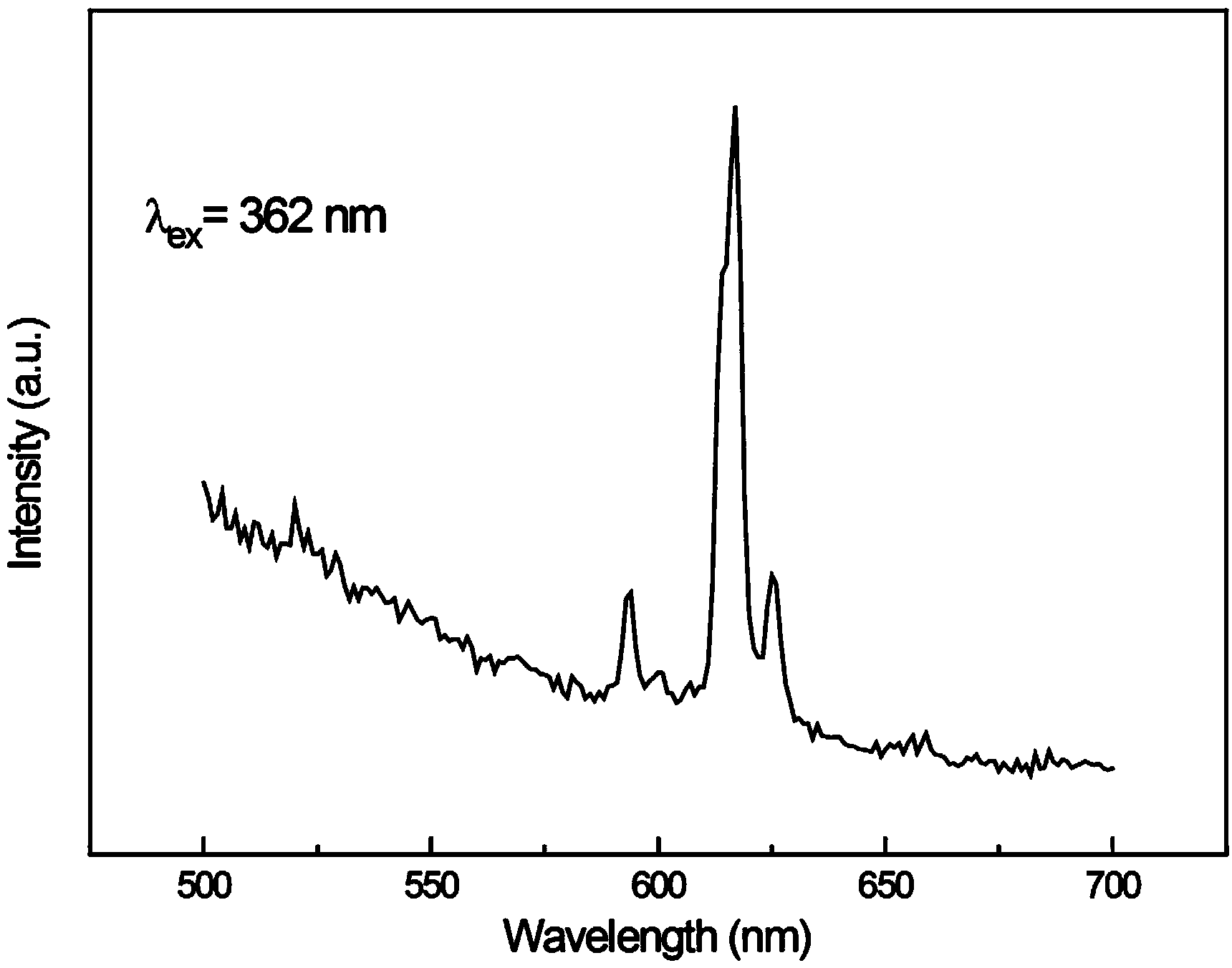

[0021] Embodiment 1: Cd 0.9992 WO 4 :Sb 3+ 0.0002 Eu 3+ 0.0006 Preparation of single-matrix tungstate phosphor

[0022] 1) Weigh 0.0006g antimony oxide (Sb 2 o 3 ), 0.0021g europium oxide (Eu 2 o 3 ), 6.1645g cadmium nitrate (Cd(NO 3 ) 2 4H 2 O), 6.5974g sodium tungstate (Na 2 WO 4 2H 2 o).

[0023] 2) Use concentrated nitric acid to completely dissolve antimony oxide (Sb 2 o 3 ) and europium oxide (Eu 2 o 3 ), were formulated into antimony nitrate and europium nitrate solutions, and zinc nitrate (Cd(NO 3 ) 2 4H 2 O) and sodium tungstate (Na 2 WO 4 2H 2 O) were dissolved in distilled water to prepare their own solutions.

[0024] 3) Fully mix antimony nitrate, europium nitrate and cadmium nitrate solutions, and add sodium tungstate solution drop by drop under constant stirring. After the dropwise addition is completed, continue stirring for 30 minutes to form a tungstate precipitate, suction filter, and dry at 60°C , prepared as a precursor;

[0025...

Embodiment 2

[0026] Embodiment 2: Cd 0.992 WO 4 :Sb 3+ 0.002 Eu 3+ 0.006 Preparation of single-matrix tungstate phosphor

[0027] 1) Weigh 0.0058g antimony oxide (Sb 2 o 3 ), 0.0211g europium oxide (Eu 2 o 3 ), 6.1200g cadmium nitrate (Cd(NO 3 ) 2 4H 2 O), 6.5974g sodium tungstate (Na 2 WO 4 2H 2 o).

[0028] 2) Use concentrated nitric acid to completely dissolve antimony oxide (Sb 2 o 3 ) and europium oxide (Eu 2 o 3 ), were formulated into antimony nitrate and europium nitrate solutions, and zinc nitrate (Cd(NO 3 ) 2 4H 2 O) and sodium tungstate (Na 2 WO 4 2H 2 O) were dissolved in distilled water to prepare their own solutions.

[0029] 3) Fully mix antimony nitrate, europium nitrate and cadmium nitrate solutions, add sodium tungstate solution drop by drop under continuous stirring, after the dropwise addition is completed, continue stirring for 40 minutes, and tungstate precipitate will be formed Suction filtration, drying at 80 °C , prepared as a precursor;...

Embodiment 3

[0031] Embodiment three: Cd 0.9894 WO 4 :Sb 3+ 0.01 Eu 3+ 0.0006 Preparation of single-matrix tungstate phosphor

[0032] 1) Weigh 0.0292g antimony oxide (Sb 2 o 3 ), 0.0021g europium oxide (Eu 2 o 3 ), 6.1040g cadmium nitrate (Cd(NO 3 ) 2 4H 2 O), 6.5974g sodium tungstate (Na2WO 4 2H2 o).

[0033] 2) Use concentrated nitric acid to completely dissolve antimony oxide (Sb 2 o 3 ) and europium oxide (Eu 2 o 3 ), were formulated into antimony nitrate and europium nitrate solutions, and zinc nitrate (Cd(NO 3 ) 2 4H 2 O) and sodium tungstate (Na 2 WO 4 2H 2 O) were dissolved in distilled water to prepare their own solutions.

[0034] 3) Fully mix antimony nitrate, europium nitrate and cadmium nitrate solutions, add sodium tungstate solution drop by drop under continuous stirring, after the dropwise addition is completed, continue stirring for 40 minutes, and tungstate precipitate will be formed Suction filtration, drying at 80 °C , prepared as a precursor;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com