Preparation method of core rod of Yb doped quartz fiber preform

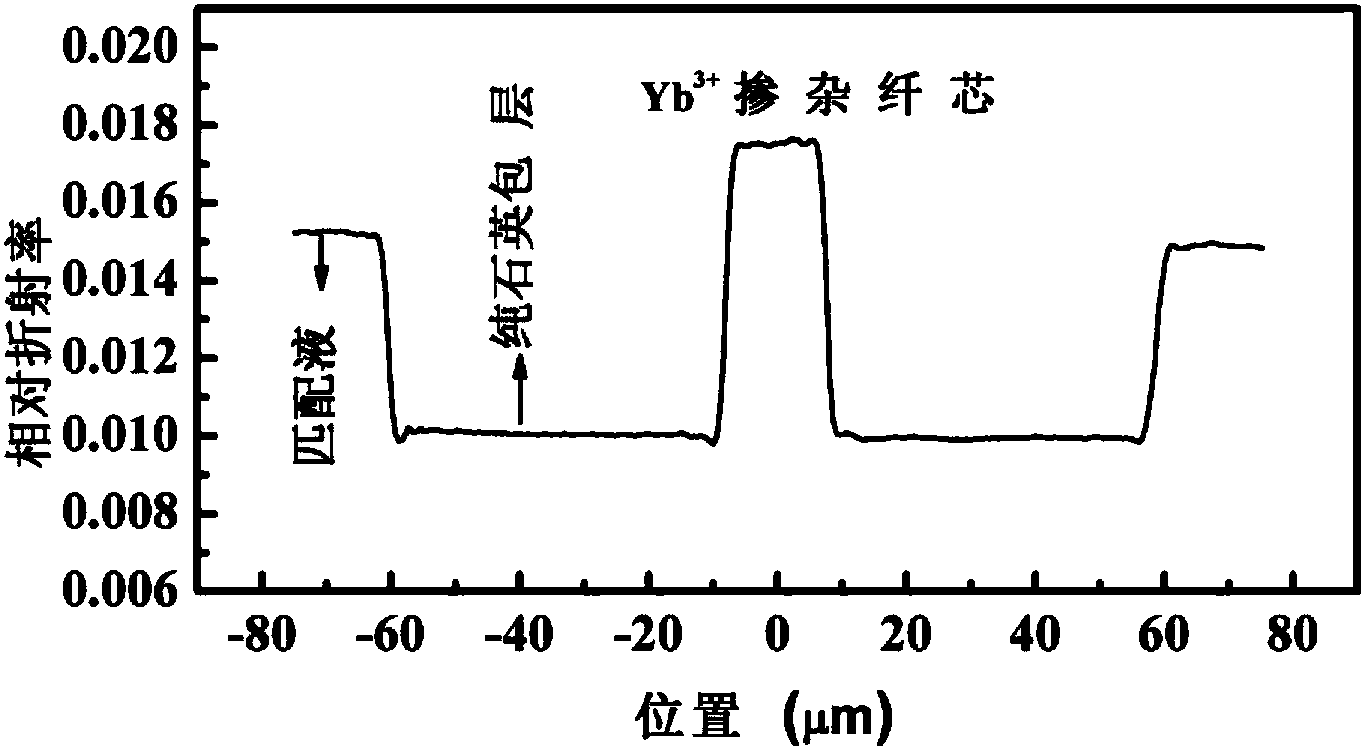

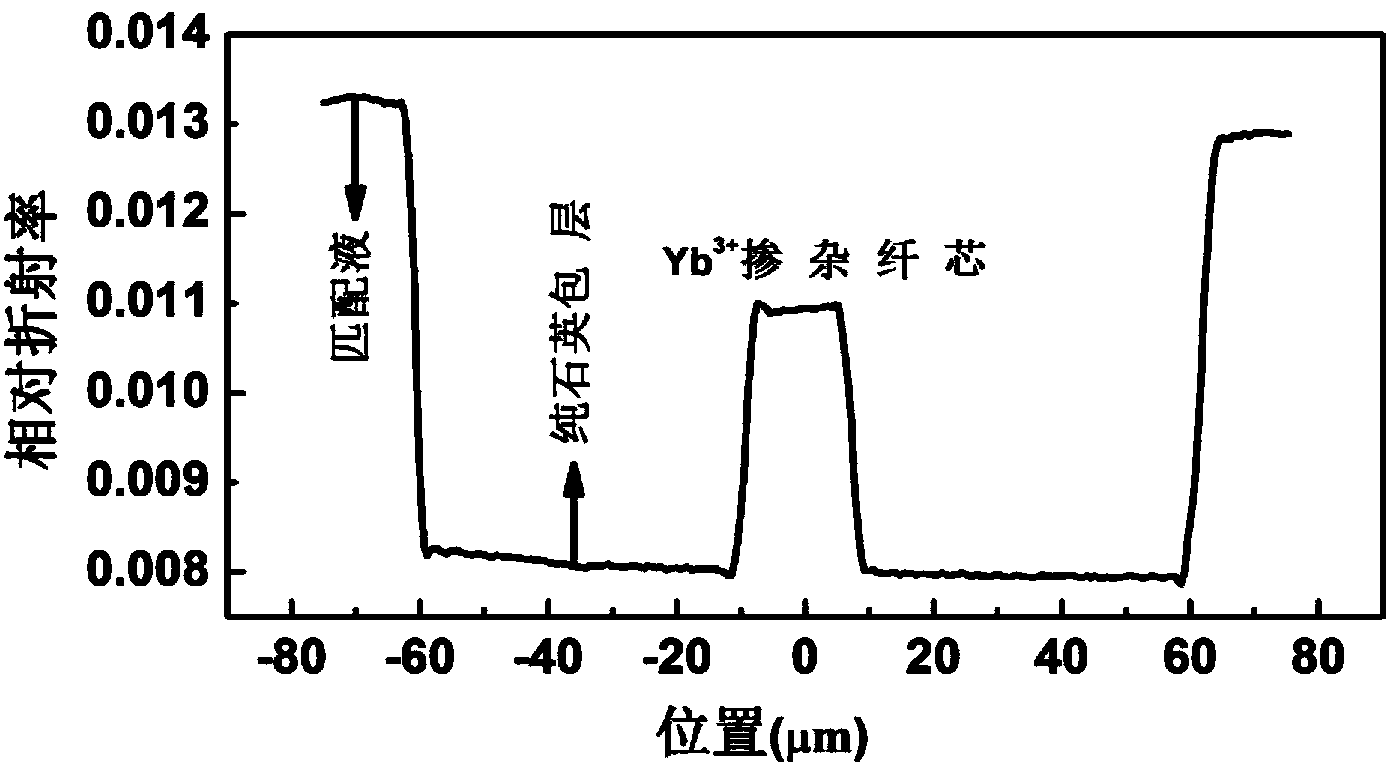

A technology of silica optical fiber and prefabricated rod, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem that it is difficult to realize the preparation of rare earth doped quartz core rod with large core diameter, and it is not clear that large size rare earth doped quartz glass core rod can be obtained and other problems, to achieve the effect of low hydroxyl content, low hydroxyl content, and uniform distribution of the refractive index of the fiber core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

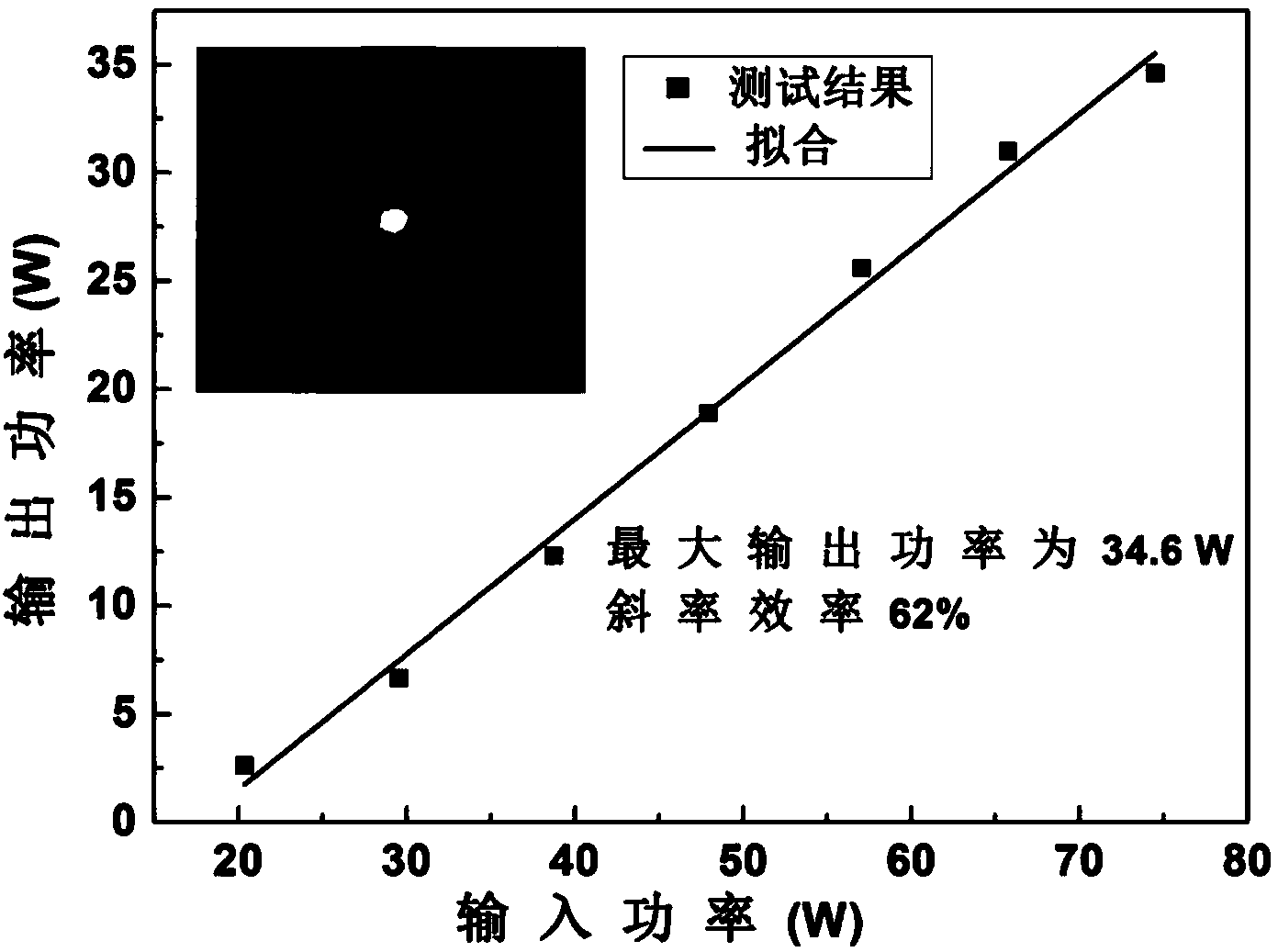

Examples

Embodiment 1

[0030] The preparation method of the Yb-doped silica optical fiber preform core of the present embodiment comprises the following steps:

[0031] ① The composition of the Yb-doped silica fiber preform core is: 0.3Yb 2 o 3 -1P 2 o 5 -3Al 2 o 3 -95.7SiO2 2 Weigh the raw material silicon alkoxide Si(OC 2 h 5 ) 4 , Ytterbium Chloride Hexahydrate YbCl 3 ·6H 2 O, aluminum chloride hexahydrate AlCl 3 ·6H 2 O and Phosphate H 3 PO 4 ;

[0032] Under room temperature and magnetic stirring, according to Si(OC 2 h 5 ) 4 :C 2 h 5 OH:H 2 The ratio of O=1:2:4 (mol ratio), with NH 4 OH is the catalyst, configure a transparent sol liquid, the solution pH=8, and then add AlCl 3 ·6H 2 O, H 3 PO 4 and YbCl 3 ·6H 2 O, stirred at room temperature for 1 hour to form a transparent doped sol, and left to stand in a closed container for 10 days;

[0033] ② Put the transparent silica sol solution in an open flask and heat it in a water bath at 100°C. After the solution loses ...

Embodiment 2

[0039] The core rod glass formula: 0.1Yb 2 o 3 -1Al 2 o 3 -98.9SiO2 2 (mol%). The preparation method of this core rod glass comprises the following steps:

[0040] The first step: under room temperature and magnetic stirring, according to Si(OC 2 h 5 ) 4 :C 2 h 5 OH:H 2 The ratio of O=1:5:20 (mol ratio), using hydrochloric acid as a catalyst, configure a transparent sol liquid, and the solution pH=1. Then according to the designed core rod glass formula, add AlCl 3 ·6H 2 O and YbCl 3 ·6H 2 O, stirred at room temperature for 10 hours to form a transparent doped sol, and left to stand in a closed container for 1 day;

[0041] Step 2: Put the sol in an open flask and heat it in a water bath at 100°C. After the solution loses its fluidity and turns into a gel, keep the gel in a tube furnace with an oxygen atmosphere of 1 atmosphere and keep it warm at 800°C for 12 hours Removal of residual carbon and hydroxyl groups to obtain uniformly doped Yb 3+ and Al 3+ silic...

Embodiment 3

[0047] The mandrel glass formula: 0.15Yb 2 o 3 -8P 2 o 5 -4Al 2 o 3 -87.85SiO 2 (mol%). The preparation method of this core rod glass comprises the following steps:

[0048] The first step: under room temperature and magnetic stirring, according to Si(OCH 3 ) 4 :CH 3 OH:H 2 The ratio of O=1:10:10 (mol ratio), using hydrochloric acid as a catalyst, configure a transparent sol liquid, and the solution pH=1. Then according to the designed core rod glass formula, add AlCl 3 ·6H 2 O, H 3 PO 4 and YbCl 3 ·6H 2 O, stirred at room temperature for 5 hours to form a transparent doped sol, and left to stand in a closed container for 1 day;

[0049] Step 2: Put the sol in an open flask and heat it in a water bath at 100°C. After the solution loses its fluidity and turns into a gel, keep the gel in a tube furnace with an oxygen atmosphere of 1 atmosphere and heat at 850°C for 10 hours Removal of residual carbon and hydroxyl groups to obtain uniformly doped Yb 3+ 、Al 3+ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com