Method for preparing methylphenol by hydroxylating methylbenzene

A technology of hydroxylation and hydroxylation of toluene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as equipment corrosion, complex process routes, and low economic value of by-products, and achieve high conversion rates and high product yields. good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

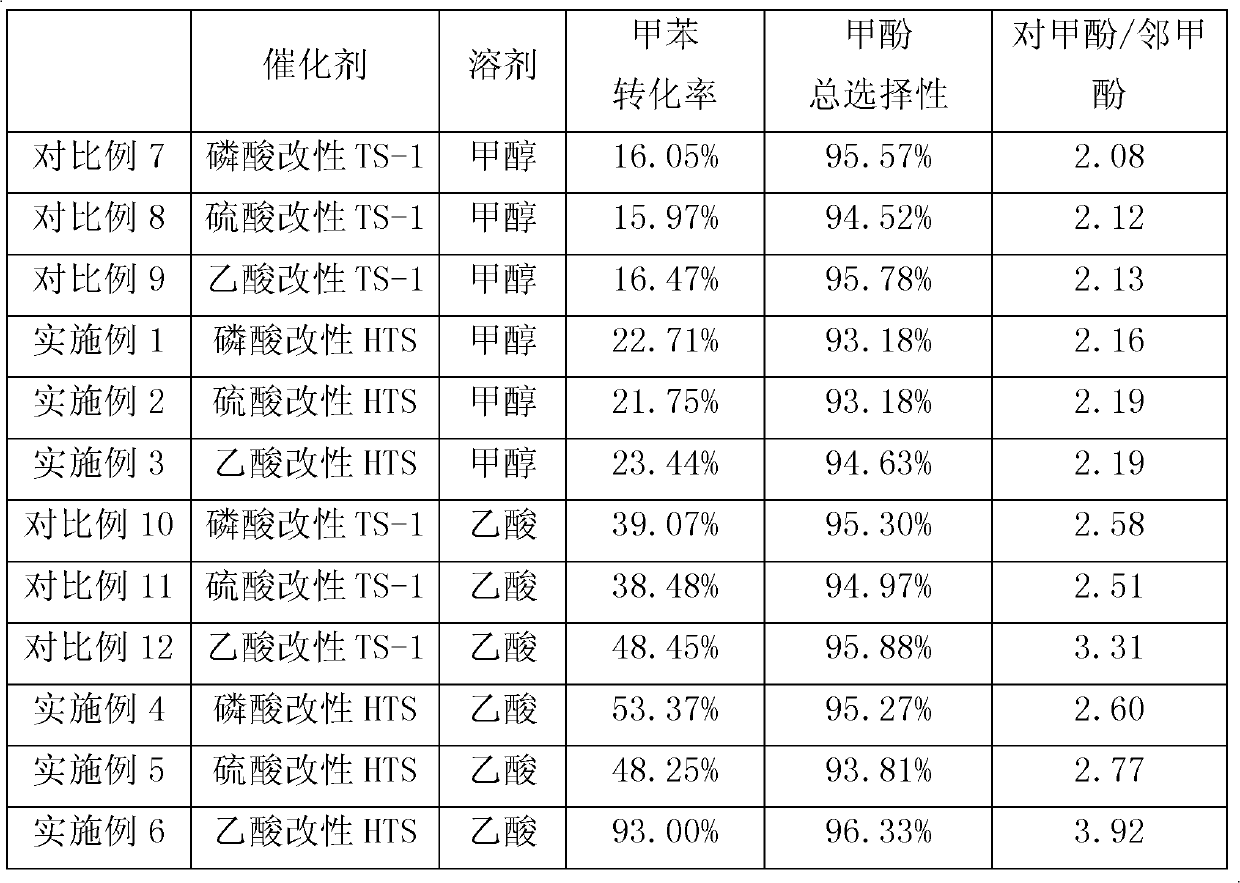

[0065] The difference from Comparative Example 7 is that the HTS molecular sieve is acid-modified.

[0066] Weigh 2.4g of modified HTS, 8.0g of toluene, methanol, and hydrogen peroxide (30%) in a 100mL slurry bed reactor with condensing reflux and mechanical stirring and mix well. Among them, toluene / methanol / hydrogen peroxide (molar ratio)=1 / 3 / 0.75. After stirring and reacting at 60° C. for 4 h, the reaction was rapidly cooled at low temperature to terminate the reaction, and samples were taken for analysis after centrifugation. The analysis results are shown in Table 2.

Embodiment 2

[0068] The difference from Comparative Example 8 is that the HTS molecular sieve is acid-modified.

[0069] Weigh 1.6g of modified HTS, 8.0g of toluene, methanol, and hydrogen peroxide (30%) in a 100mL slurry bed reactor with condensing reflux and mechanical stirring and mix well. Among them, toluene / methanol / hydrogen peroxide (molar ratio)=1 / 5 / 1. After stirring and reacting at 50° C. for 6 h, the reaction was rapidly cooled at low temperature to terminate the reaction, and samples were taken for analysis after centrifugation. The analysis results are shown in Table 2.

Embodiment 3

[0071] The difference from Comparative Example 9 is that the HTS molecular sieve is acid-modified.

[0072] Weigh 1.6g of modified HTS, 8.0g of toluene, methanol, and hydrogen peroxide (30%) in a 100mL slurry bed reactor with condensing reflux and mechanical stirring and mix well. Among them, toluene / methanol / hydrogen peroxide (molar ratio)=1 / 7 / 0.8. After stirring and reacting at 80° C. for 6 h, the reaction was rapidly cooled at low temperature to terminate the reaction, and samples were taken for analysis after centrifugation. The analysis results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com