High-purity arsenic preparation method

A high-purity arsenic and equipment technology, applied in the field of high-purity arsenic preparation, to achieve the effect of large solubility difference, high purity, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Main process equipment: oxidation reactor, esterification-rectification coupling reactor, reduction reactor, adsorption impurity removal equipment and hydrolysis-crystallization equipment are stirring tanks, solid-liquid separation equipment is sedimentation solid-liquid separator, etc.

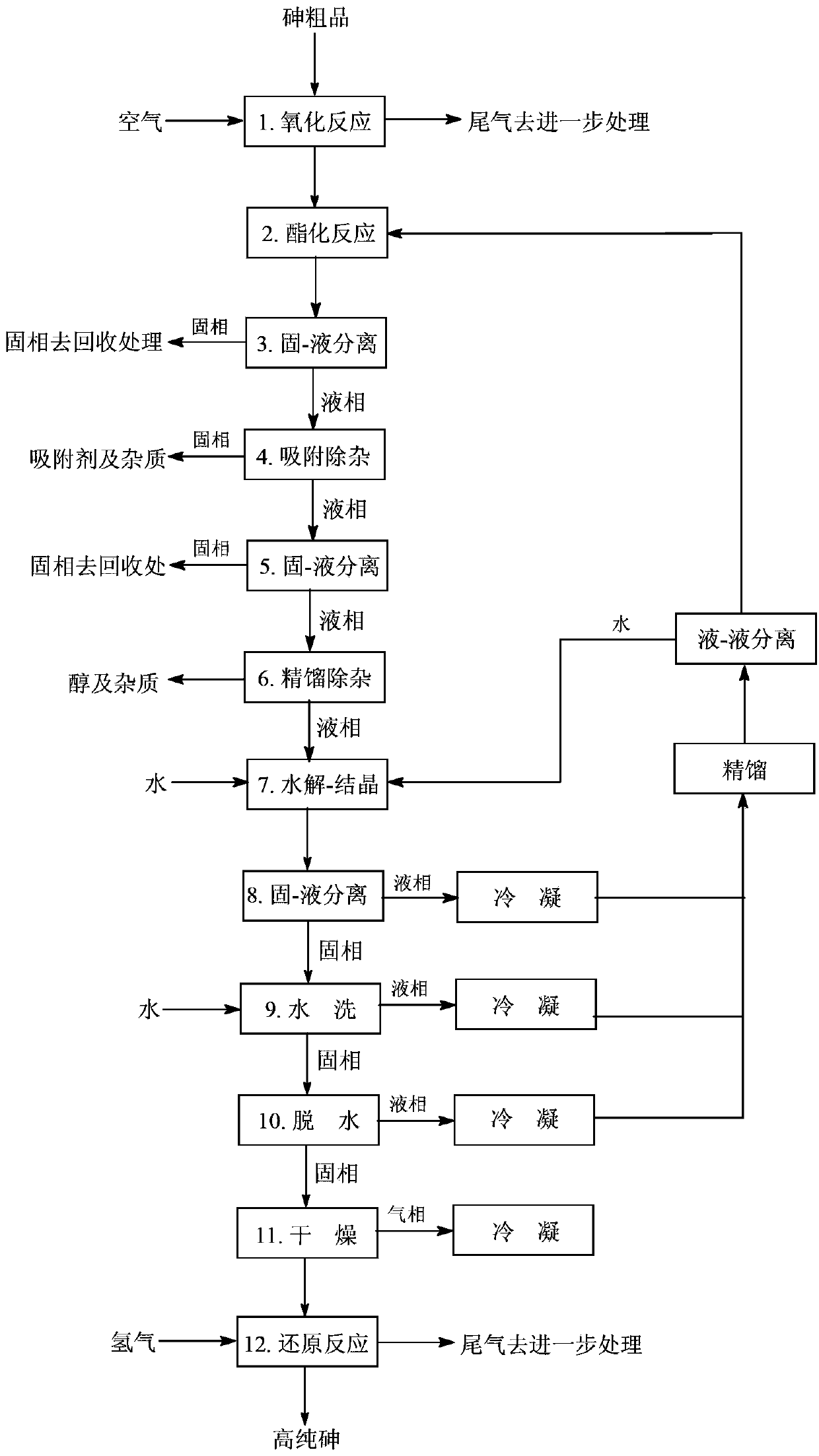

[0077] like figure 1 As shown, a method for preparing high-purity arsenic, especially a process for preparing high-purity arsenic by using the crude industrial arsenic product as a raw material using oxidation-esterification-rectification-hydrolysis-reduction coupling technology, the steps are as follows:

[0078] (1) Oxidation reaction: In the oxidation reactor, the industrial arsenic crude product is mixed with air, and the arsenic and oxygen undergo an oxidation reaction at a reaction temperature of 400°C to form arsenic oxide, and the arsenic oxide gas is condensed to 120°C to obtain arsenic oxide solid, of which arsenic trioxide The mass fraction content is higher than 99%;

[00...

Embodiment 2

[0091] Main process equipment: oxidation reactor, esterification-distillation coupling reactor, reduction reactor, adsorption impurity removal equipment and hydrolysis-crystallization equipment are stirring tanks, solid-liquid separation equipment is filter press solid-liquid separator, etc.

[0092] Proceed as follows:

[0093] (1) Oxidation reaction: In the oxidation reactor, the industrial arsenic crude product is mixed with air, and the arsenic and oxygen undergo an oxidation reaction at a reaction temperature of 600°C to form arsenic oxide, and the arsenic oxide gas is condensed to 180°C to obtain arsenic oxide solid, of which arsenic trioxide The mass fraction content is higher than 99%;

[0094] (2) Esterification reaction: in the esterification-distillation coupled reactor, add diarsenic trioxide crude product and isopropanol, the mass percent content of water in isopropanol is 20%, the molar ratio of diarsenic trioxide and alcohol is 1:24, then Heat the material to a...

Embodiment 3

[0106] Main process equipment: oxidation reactor, esterification-rectification coupling reactor, reduction reactor, adsorption impurity removal equipment and hydrolysis-crystallization equipment are stirred tanks, solid-liquid separation equipment is centrifugal solid-liquid separator, etc.

[0107] Proceed as follows:

[0108] (1) Oxidation reaction: In the oxidation reactor, the industrial arsenic crude product is mixed with air, and the arsenic and oxygen undergo an oxidation reaction at a reaction temperature of 400°C to 600°C to form arsenic oxide, and the arsenic oxide gas is condensed to 120°C to 180°C to obtain Arsenic oxide solid, wherein the mass fraction of arsenic trioxide is higher than 99%;

[0109] (2) Esterification: In the esterification-rectification coupled reactor, add the crude product of diarsenic trioxide and n-butanol, the mass percentage of water in n-butanol is 10%, and the molar ratio of diarsenic trioxide to alcohol is 1:16, Then the material is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com