Nebrodensis cultivation material compatibility and manufacturing method of cultivation material

The technology of cultivation material and Bailing mushroom is applied in fertilizer mixture, fertilization device, application and other directions, which can solve the problems of air, water source and ecological environment pollution, and the proportion of processing is not large, so as to broaden the channels of cultivation raw materials, increase production, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

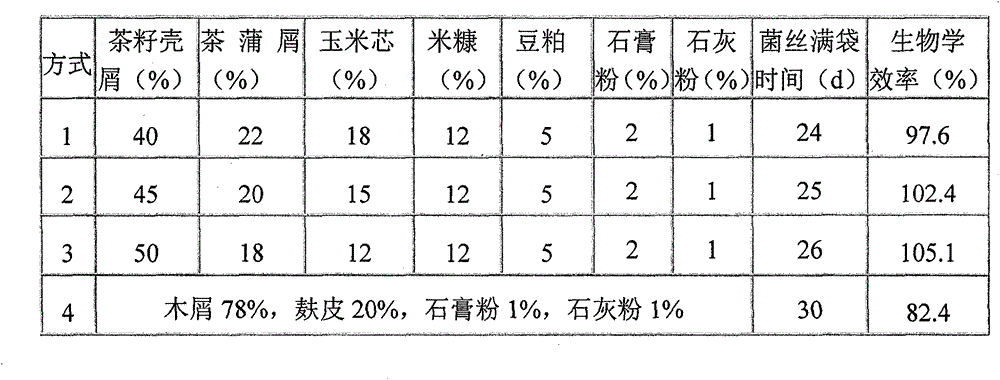

[0027] Method 1: In this example, the Bailing mushroom cultivation material includes the following components and mass ratio: 40% of tea seed husk, 22% of tea cattail, 18% of corn cob, 12% of rice bran, 5% of soybean meal, 2% of gypsum powder %, lime powder 1%, are all the quality of dry matter, and the sum of proportioning is 100%.

[0028] Production Method:

[0029] ①Sunning material: Expose the raw material for 1 day before mixing the material, and use ultraviolet rays to kill some bacteria in the raw material;

[0030] ②Pre-wetting: First, mix the tea seed husk and tea cattail in a dry state evenly, and then pre-wet with 1% lime aqueous solution (fully soaked);

[0031] ③ Stacking fermentation: Pile the wet material into a trapezoidal pile with a height of 1.0m, a width of 2m-3m, and an unlimited length. Vertical air holes, straight to the bottom of the pile, the air hole density is 1 / m 3 , and finally covered with thatch to let it ferment naturally;

[0032] ④Turning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com