Preparation method of nano immobilized cellulase

A cellulase and cellulose technology, which is applied in the direction of being fixed on or in an inorganic carrier, can solve the problems of low enzymatic activity retention rate, incapable of industrialized production, complicated preparation process, etc., and achieves a simple and environmentally friendly method for repeated use. , the effect of compensating for production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of nano-immobilized cellulase according to the present invention

[0036] Materials Orthoethyl silicate (TEOS), Sinopharm Reagent Group, purity > 99%

[0037] Cellulase, Sigma Aldrich, 10000U / g

[0038] D-Glucose, Aladdin's reagent, >99%

[0039]Accurately weigh 32.0g of tetraethyl orthosilicate (TEOS) into a 100ml beaker, add 2.5ml of 0.5M HCl solution under stirring, after vigorous stirring, the tetraethyl orthosilicate can be hydrolyzed after about 15min to obtain transparent solution, the transparent solution obtained after hydrolysis was cooled in a 4°C refrigerator, and then transferred to a conical flask with a high vacuum system to recover the ethanol obtained in the hydrolysis process. When the quality of the entire system dropped to 50% of its original value (at this time ethanol content in the solution <1%), stop vacuuming, transfer the solution into a 100ml beaker, add glucose solution (2.0g glucose dissolved in 10ml water) under ...

Embodiment 2

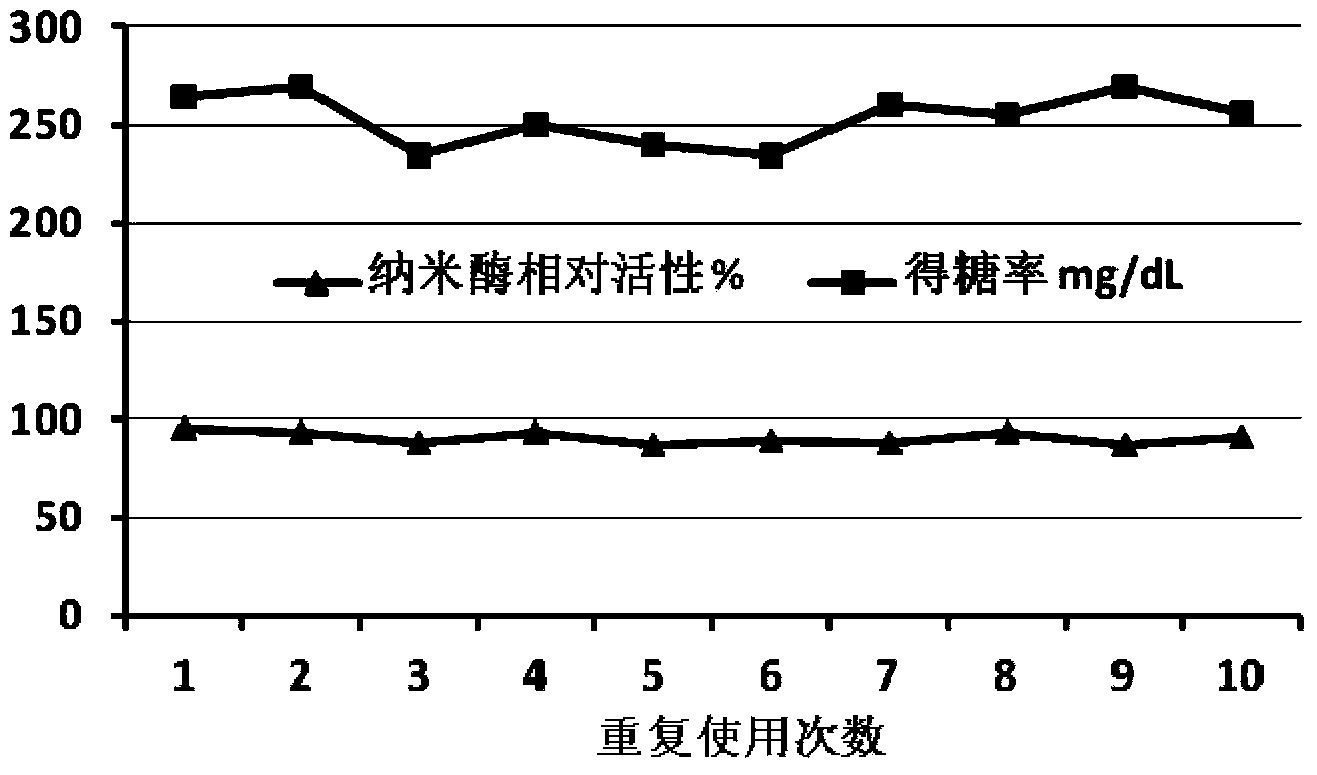

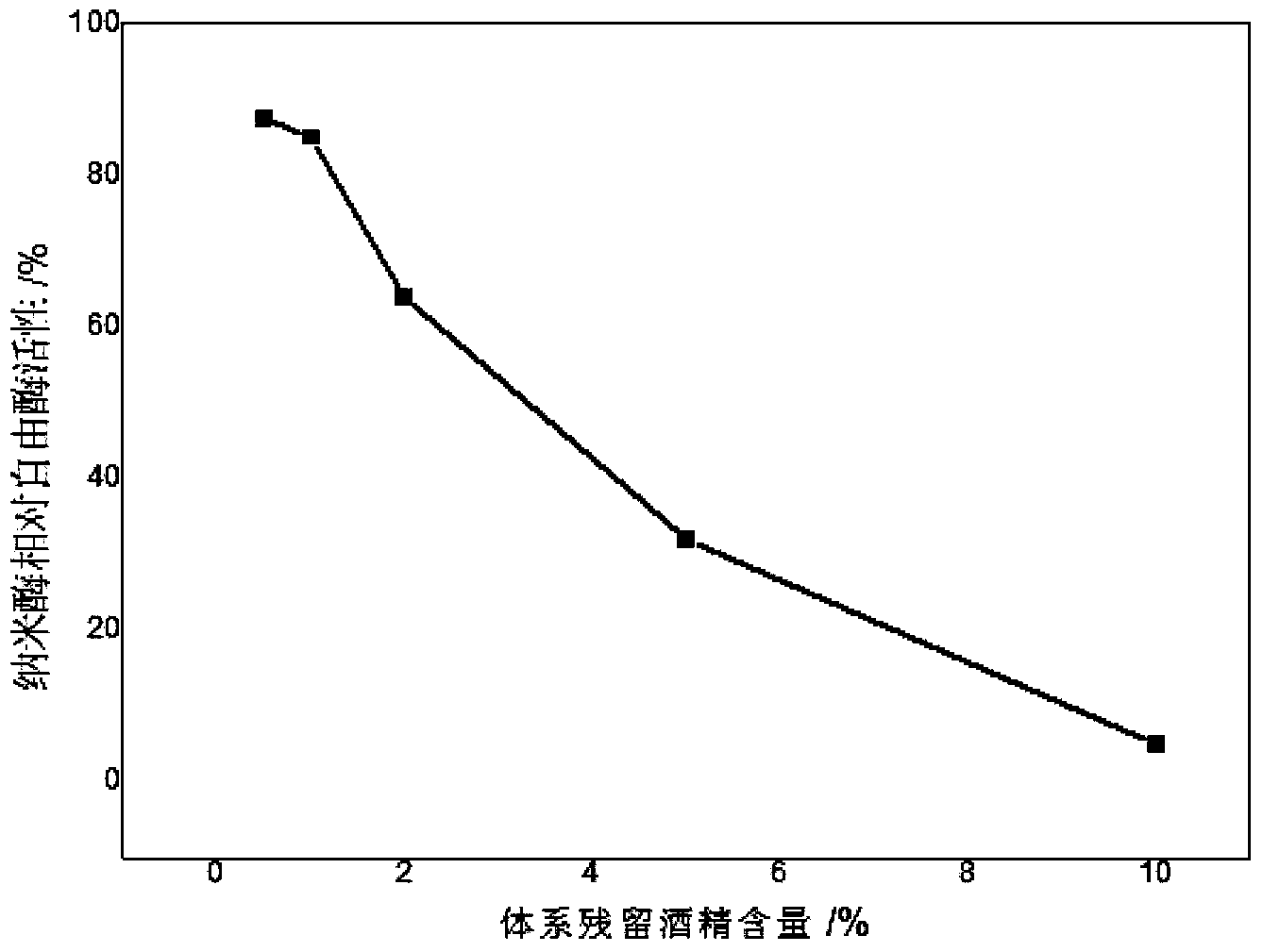

[0040] Example 2: Influence of residual ethanol in the system on the activity of nano-immobilized cellulase in the preparation method of the present invention

[0041] With reference to Example 1, keeping other conditions unchanged, the ethanol content in the transparent solution was controlled to be 0.5%, 1.0%, 2.0%, 5.0%, and 10% respectively after recovering ethanol, and the prepared nano-cellulase was measured for enzyme activity, and the results See table below.

[0042] System residual ethanol%

[0043] The above results show that when the ethanol content in the transparent solution is less than 1% after controlling the recovery of ethanol, the relative free enzyme activity of the nanozyme is above 85%.

Embodiment 3

[0044] Embodiment 3: Nano-immobilized cellulase activity test of the present invention

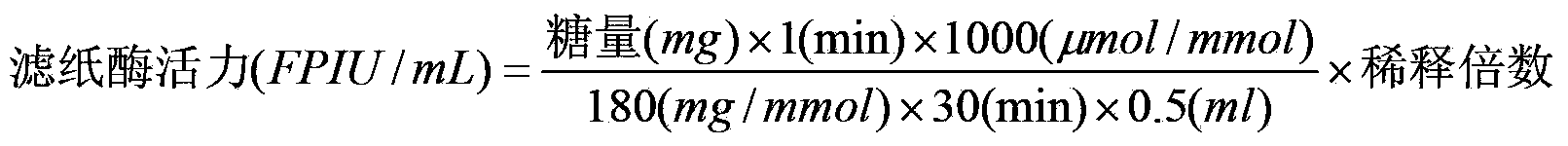

[0045] Usually, filter paper activity (FPA) represents the total activity of cellulase, which is measured according to the international standard method recommended by the International Union of Theoretical and Applied Chemistry (IUPAC), and expressed in IU. Put a piece of 1×6cm whatman No.1 filter paper (about 50mg) into the test tube, add 0.5mL of appropriately diluted cellulase solution and 1mL of citric acid buffer (pH4.8), and incubate and shake at 50°C for 30min. In the blank test, except that the enzyme solution was inactivated in advance, the other conditions were unchanged. After the reaction, the resulting reducing sugar content was determined by the DNS method.

[0046] One filter paper enzyme activity international unit (FPIU) is equal to the amount of enzyme required to generate 1.0umol of glucose (expressed as reducing sugar) per minute in the enzymatic reaction. Then there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com