Preparation method of high-resilience polyester industrial filament yarns for supplementary restraint system

An airbag and recovery technology, which is applied in filament forming treatment, filament/thread forming, artificial filament heat treatment, etc., can solve the problem of performance degradation and achieve the effect of improving compression resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]The invention provides a method for preparing high elastic recovery polyester industrial filaments for airbags. The raw material used is low-viscosity PET slices with a viscosity of 0.67dl / g, and the low-viscosity slices are heated under the protection of hot nitrogen at 210°C-220°C. Carry out solid phase repolymerization under high temperature conditions for 25-35 hours, and the prepared high-viscosity slices have a moisture content of less than 30ppm and a viscosity of 0.9-1.0dl / g. The prepared high-viscosity slices are melt-spun at 290°C-320°C. The equipment used is a screw extruder, and the slices are melted uniformly in the screw extruder, with low thermal degradation and low loss of melt viscosity. The screw extruder makes the obtained spinning melt have good properties. The screw diameter of the screw extruder is 90-150mm, the aspect ratio is 25-30, and the melting temperature is 290°C-320°C. After the high-viscosity PET chips are transported to the screw extruder...

specific Embodiment 1

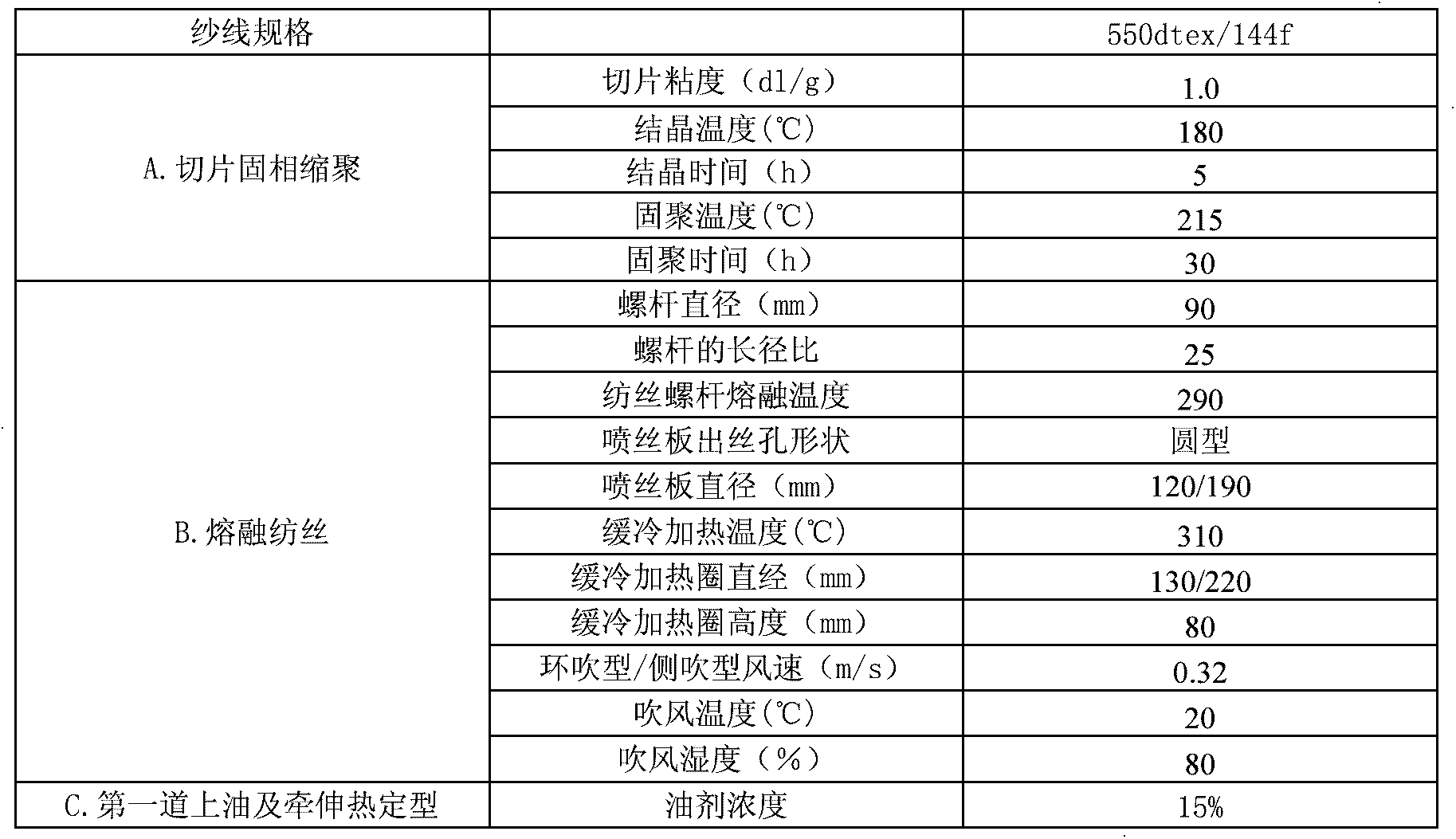

[0038] The implementation process is as described above, and the implementation process parameters are shown in the following table:

[0039] Table 1 Preparation parameters of a kind of high elastic recovery polyester industrial filament for airbag

[0040]

[0041]

[0042] Wherein, the formula of the first high temperature resistant oil agent is: mineral oil, 32%; sodium lauryl sulfonate, 3%; oleic acid diethanolamide, 20%; isotridecanyl stearate, 35% ; Tert-Butyl Cellosolve, 5%; Phthalates, 5%.

[0043] The formula of the second high temperature resistant oil agent is: mineral oil, 35%; sodium lauryl sulfonate, 2%; oleic acid diethanolamide, 20%; isotridecanyl stearate, 35%; Butyl cellosolve, 3%; N-phenyl-β-naphthylamine, 1.5%; N-phenyl-N'-isopropyl-p-phenylenediamine, 1.5%; MCA 2%. The operating speed of the second oiling and oiling process is 3000m / min.

[0044] After the melt-spinning stage transports the obtained high-viscosity PET chips to the screw extruder, ...

specific Embodiment 2

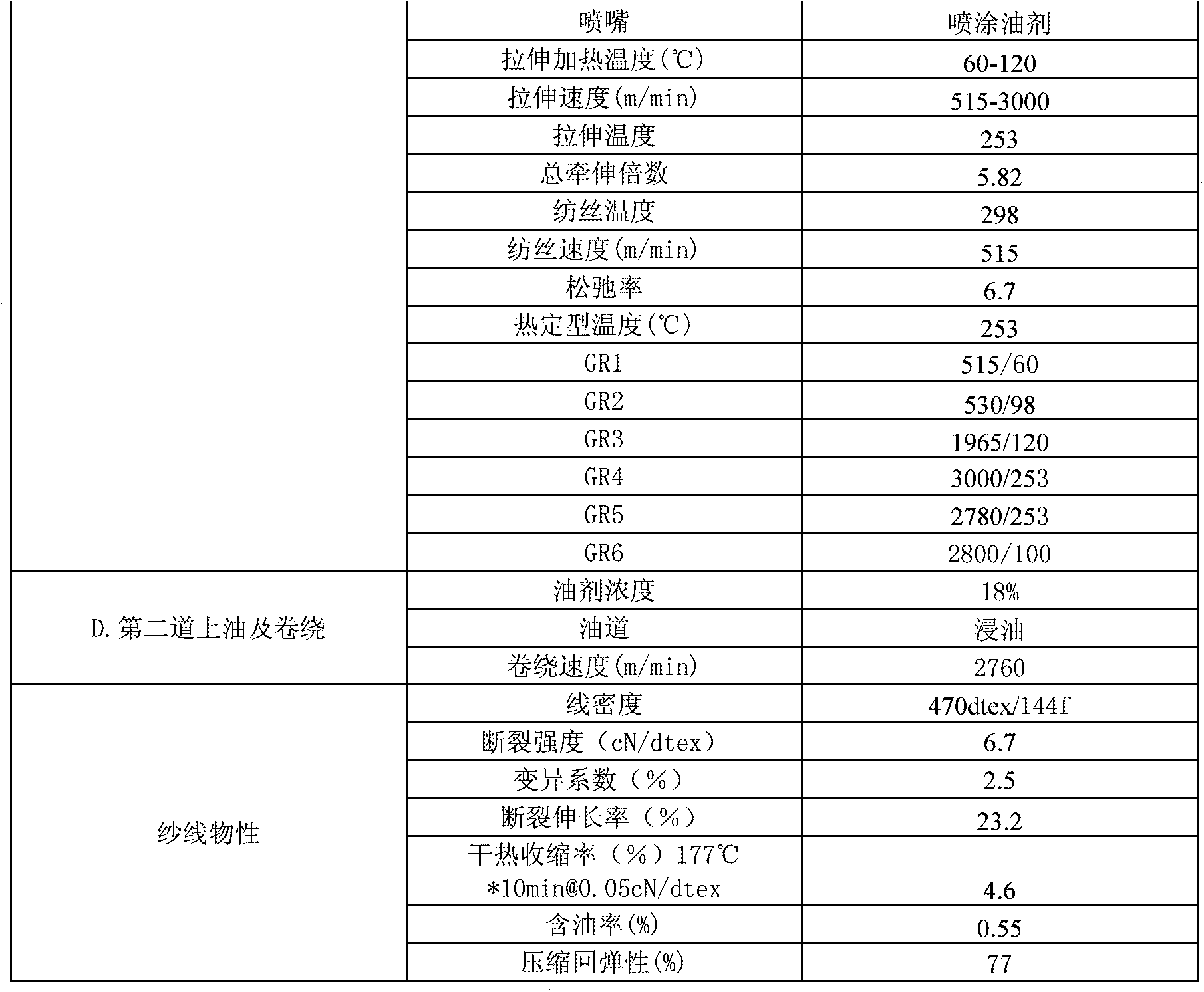

[0045] The implementation process is as described above, and the implementation process parameters are shown in the following table:

[0046] Table 2 Process parameters of a high elastic recovery polyester industrial filament for airbags

[0047]

[0048]

[0049] The formula of the first high temperature resistant oil agent is: mineral oil, 45%; sodium lauryl sulfonate, 2%; oleic acid diethanolamide, 20%; isotridecanyl stearate, 30%; Butyl Cellosolve, 2%; Phthalates, 1%.

[0050] The formula of the second high temperature resistant oil agent is: mineral oil, 50%; sodium lauryl sulfonate, 3%; oleic acid diethanolamide, 15%; isotridecanyl stearate, 25%; Butyl cellosolve, 4%; N-phenyl-β-naphthylamine, 1%; N-phenyl-N'-isopropyl-p-phenylenediamine, 1%; MCA 1%. The running speed of the second oiling is 2800m / min.

[0051] After the melt-spinning stage transports the obtained high-viscosity PET chips to the screw extruder, a plasticizer is added to the screw extruder, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com