Preparation method for oxidized grapheme in large sheet

A natural flake graphite and fossil technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high energy consumption, poor oxidation efficiency, poor peelability of graphite oxide, environmental pollution by sulfide or nitride, etc. Achieve the effect of large specific surface area, improved oxidation efficiency and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

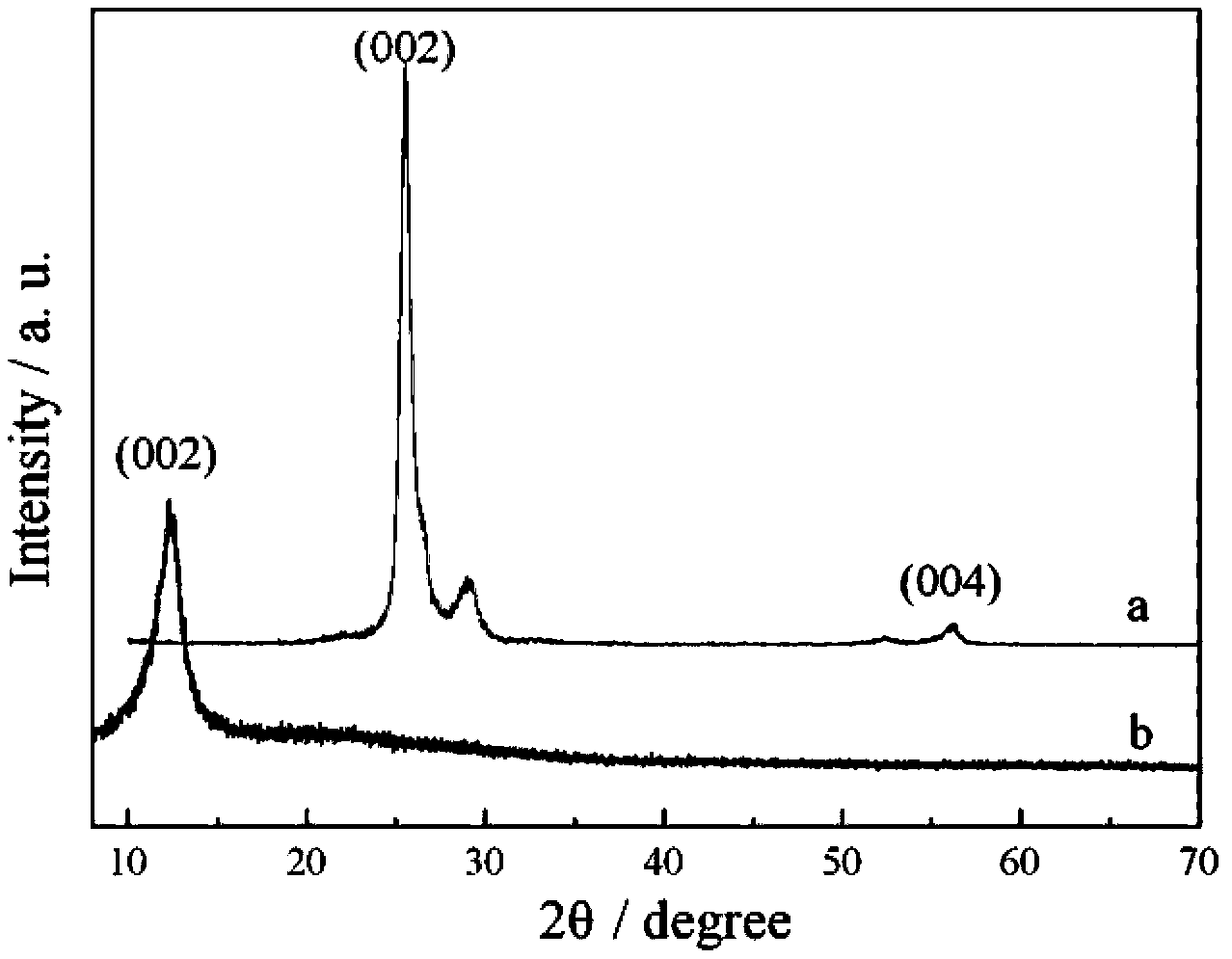

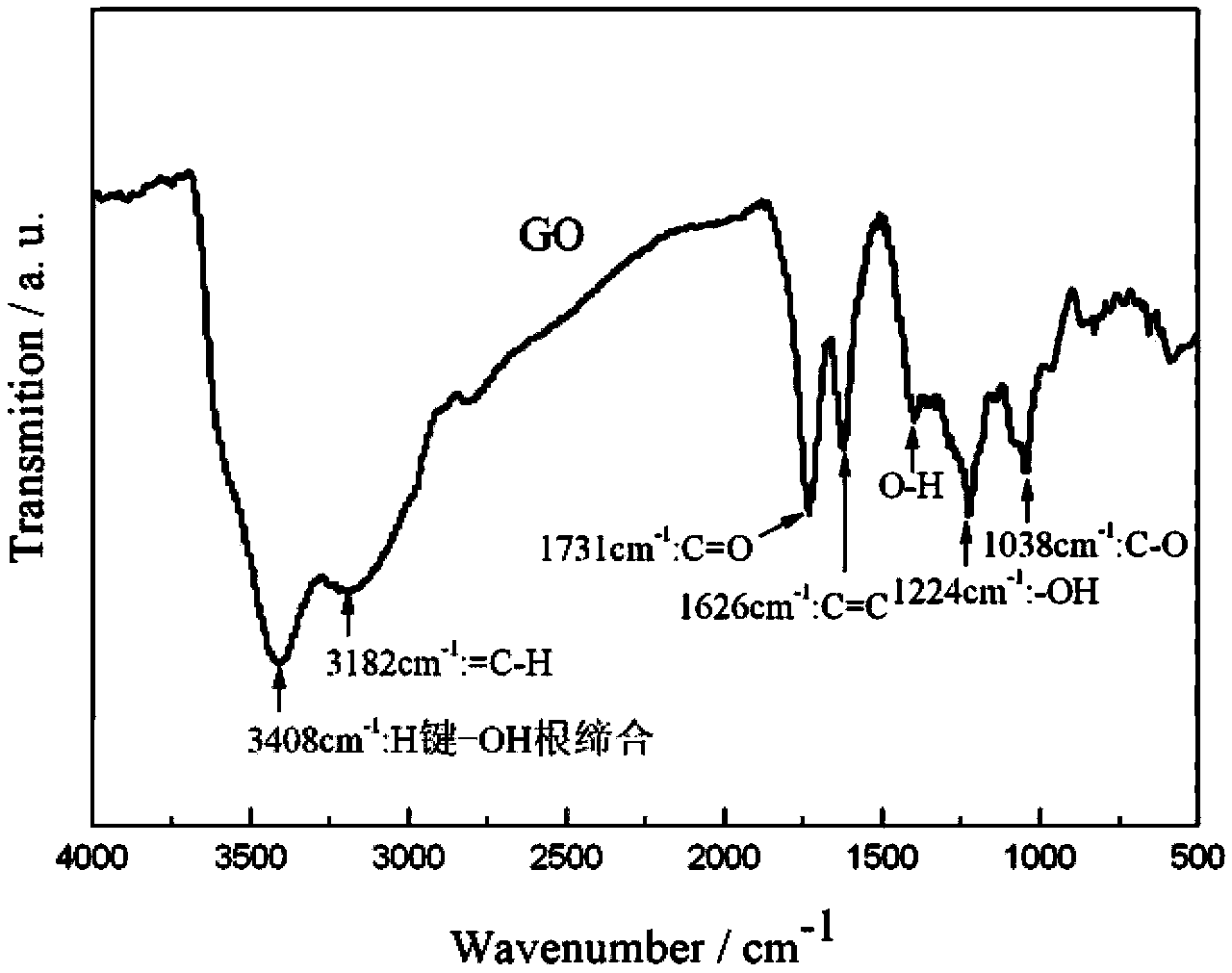

[0028] Mix 10g of natural flake graphite with a purity of 99% and a particle size of 150μm with 30mL of concentrated nitric acid, add 5mL of hydrogen peroxide with a concentration of 60% from the bottom of the reactor, stir and react for 20min, wash with water, and dry to obtain delaminated graphite; weigh 2g Mix layered graphite with 80mL of concentrated sulfuric acid, slowly add 6g of potassium permanganate, mix evenly, and conduct an ultrasonic-assisted oxidation reaction in an ice-water bath for 30min with an ultrasonic power of 40kHz; raise the temperature of the mixture to 50°C and keep stirring for 10h, then add 200mL to Stirring and reacting for 20 minutes under the assistance of ionized water ultrasound, the obtained product was first centrifuged with a mixed solution of 10% (mass percentage) dilute hydrochloric acid and 1% (mass percentage) hydrogen peroxide at a volume ratio of 1:1, and then washed with deionized water and centrifuged. Separated to obtain graphene ox...

Embodiment 2

[0034] Mix 10g of natural flake graphite with a purity of 99% and a particle size of 180μm with 40mL of concentrated nitric acid, add 7mL of hydrogen peroxide from the bottom of the reactor, stir and react for 30min, wash with water, and dry to obtain delaminated graphite; weigh 2g of delaminated graphite and 100mL Mix concentrated sulfuric acid, slowly add 8g of potassium permanganate, mix well, and conduct ultrasonic-assisted oxidation reaction in an ice-water bath for 30min, with an ultrasonic power of 50kHz; heat the mixture to 60°C and continue stirring for 12h, then add deionized water for ultrasonic-assisted stirring After reacting for 40 minutes, the obtained product was first centrifugally cleaned with a 1:1 mixed solution of 10% dilute hydrochloric acid and 1% hydrogen peroxide, then washed with deionized water, and centrifuged to prepare graphene oxide.

[0035] The TEM characterization photo of the graphene oxide sample obtained by the present embodiment refers to t...

Embodiment 3

[0037] Mix 10g of natural flake graphite with a purity of 90% and a particle size of 270μm with 50mL of concentrated nitric acid, add 10mL of hydrogen peroxide from the bottom of the reactor, stir and react for 60min, wash with water, and dry to obtain delaminated graphite; weigh 2g of delaminated graphite and 90mL Mix concentrated sulfuric acid, slowly add 8g of potassium permanganate, mix well, and then conduct ultrasonic-assisted oxidation reaction in an ice-water bath for 30min, with an ultrasonic power of 40kHz; heat the mixture to 60°C and continue stirring for 12h, then add deionized water and stir under ultrasonic assistance After reacting for 30 minutes, the obtained product was first centrifugally cleaned with a 1:1 mixed solution of 10% dilute hydrochloric acid and 1% hydrogen peroxide, then washed with deionized water, and centrifuged to prepare graphene oxide.

[0038] The TEM characterization photo of the graphene sample that obtains by example refers to attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com