Preparation method of nano-composite catalyst titanium dioxide pseudo-boehmite

A pseudo-boehmite and titanium dioxide technology, applied in the field of materials, can solve the problems of low adsorption capacity, low photocatalytic efficiency, and restrictions on the industrialization of photocatalysts, and achieve the effect of high specific surface area and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

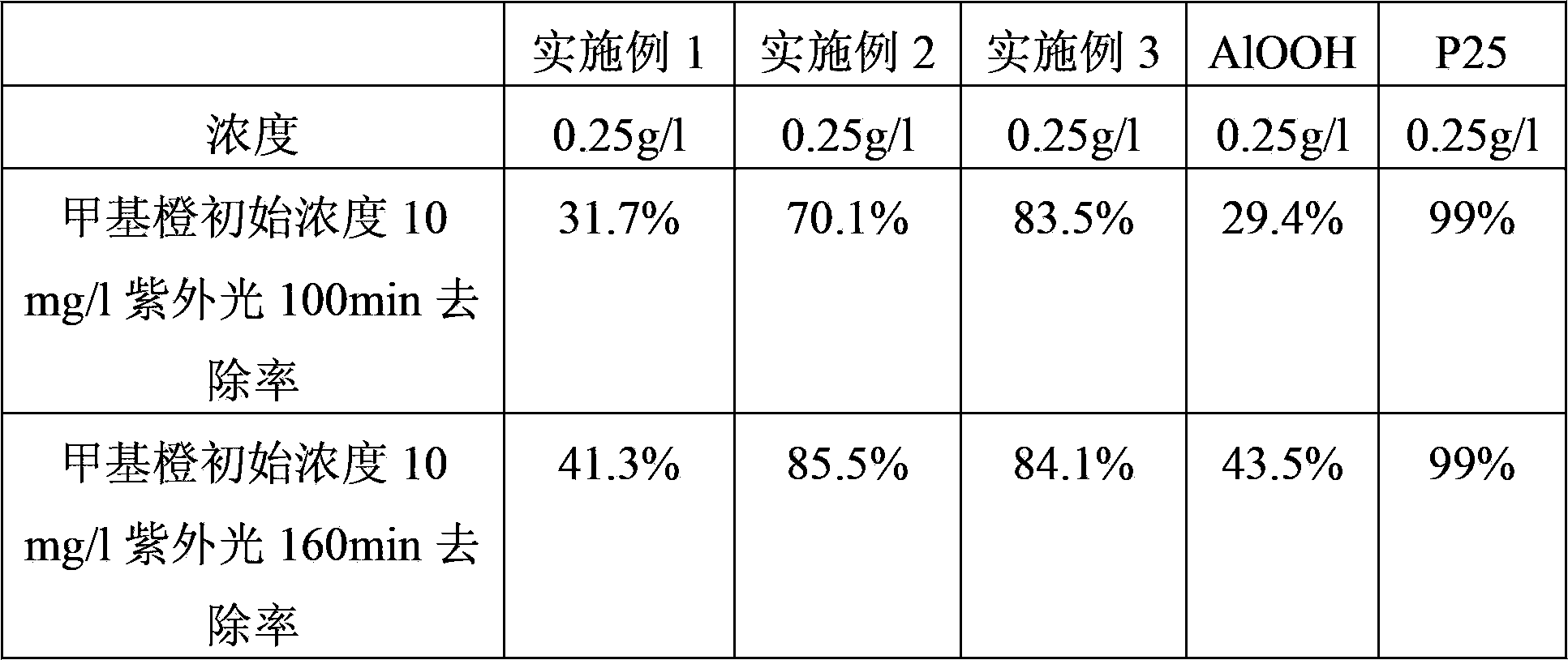

Embodiment 1

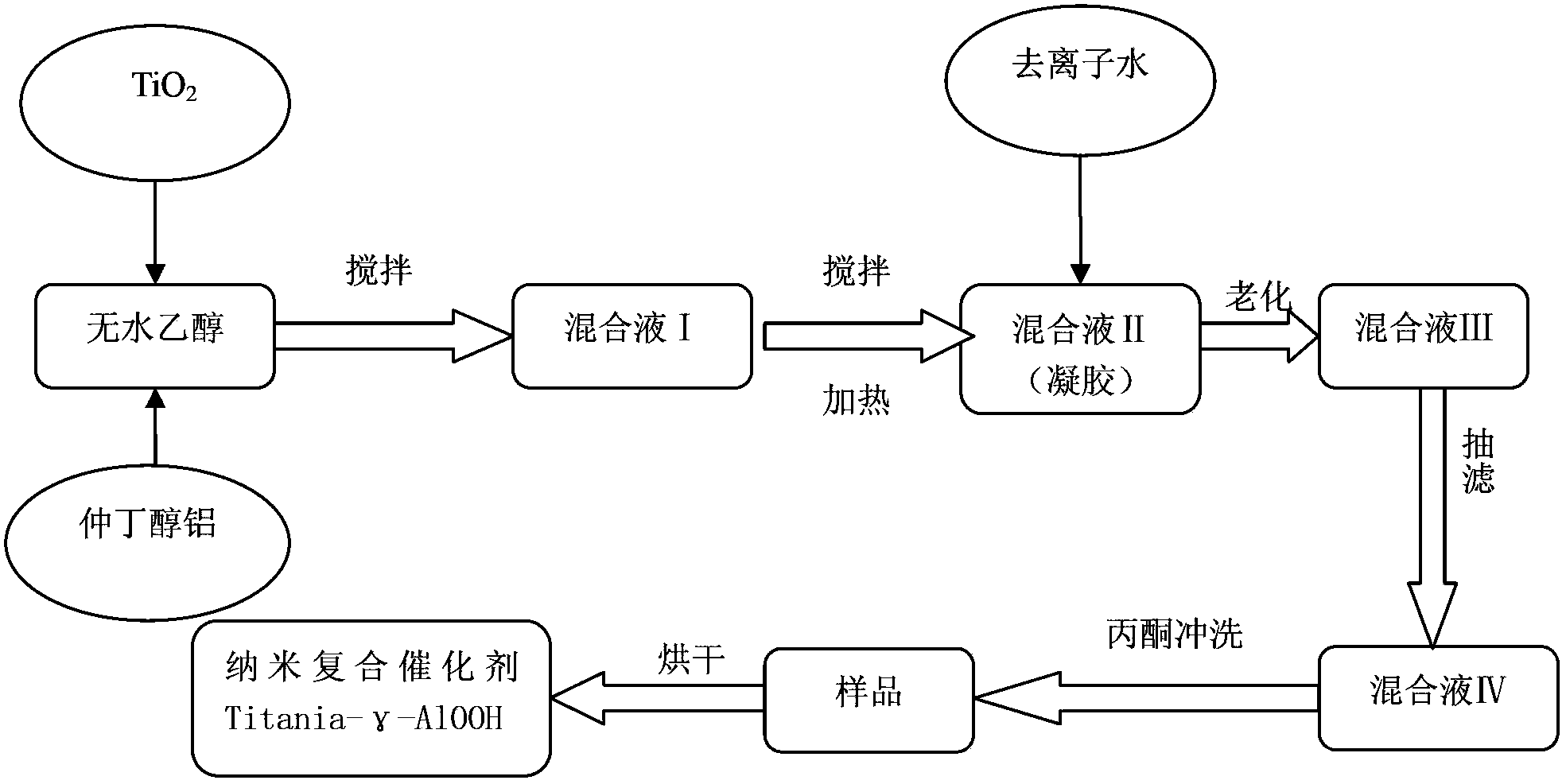

[0049] A preparation method of nanocomposite catalyst titanium dioxide pseudo-boehmite, comprising the following steps:

[0050] a. Weigh 0.3g of TiO 2 (P25) Add 8g of absolute ethanol;

[0051] b. Then add 10.9g of aluminum sec-butoxide and stir to make a mixed solution I;

[0052] c. heating and stirring the mixed solution I prepared in step b at a temperature of 150° C. for 3 hours to prepare mixed solution II, which is in the form of a gel;

[0053] d. Measure 3ml of deionized water, add it to the mixed solution II prepared in step c, and age for 3 hours to make mixed solution III;

[0054] e. Suction filter the mixed solution III prepared in step d with a suction filter to make mixed solution IV;

[0055] f. Rinse the mixed solution IV prepared in step e with acetone several times to obtain a sample;

[0056] g. Put the sample prepared in step f into a blast drying oven at 120° C. and dry for 2 hours to obtain the nanocomposite titanium dioxide pseudo-boehmite (Titani...

Embodiment 2

[0059] A preparation method of nanocomposite catalyst titanium dioxide pseudo-boehmite, comprising the following steps:

[0060] a. Weigh 0.6g of TiO 2 (P25) Add 8g of absolute ethanol;

[0061] b. Then add 5.65g of aluminum sec-butoxide and stir to make a mixed solution I;

[0062] c. heating and stirring the mixed solution I prepared in step b at a temperature of 160° C. for 3 hours to prepare mixed solution II, which is in the form of a gel;

[0063] d. Measure 2.5ml of deionized water, add it to the mixed solution II prepared in step c, and age for 3 hours to make mixed solution III;

[0064] e. Suction filter the mixed solution III prepared in step d with a suction filter to make mixed solution IV;

[0065] f. Rinse the mixed solution IV prepared in step e with acetone several times to obtain a sample;

[0066] g. Put the sample prepared in step f into a blast drying oven at 120° C. and dry for 2 hours to obtain the nanocomposite titanium dioxide pseudo-boehmite (Tita...

Embodiment 3

[0069] A preparation method of nanocomposite catalyst titanium dioxide pseudo-boehmite, comprising the following steps:

[0070] a. Weigh 0.35g of TiO 2 (P25) Add 3.6g of absolute ethanol;

[0071] b. Then add 2.126g of aluminum sec-butoxide and stir to make a mixed solution I;

[0072] c. heating and stirring the mixed solution I prepared in step b at a temperature of 140° C. for 3 hours to prepare mixed solution II, which is in the form of a gel;

[0073] d. Measure 1.3ml of deionized water, add it to the mixed solution II prepared in step c, and age for 3 hours to make mixed solution III;

[0074] e. Suction filter the mixed solution III prepared in step d with a suction filter to make mixed solution IV;

[0075] f. Rinse the mixed solution IV prepared in step e with acetone several times to obtain a sample;

[0076] g. Put the sample prepared in step f into a blast drying oven at 120° C. and dry for 2 hours to obtain the nanocomposite titanium dioxide pseudo-boehmite (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com