Hydroquinone synthetic method

A technology of hydroquinone and synthetic methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as harsh working environment, difficult technology, cumbersome intermittent operations, etc., and achieve simple and novel synthetic routes , The process is environmentally friendly, and the process is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

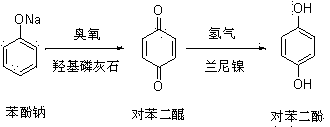

Image

Examples

Embodiment 1

[0018] Step a, synthetic benzoquinone

[0019] Take 30 grams of sodium phenate and 3 grams of hydroxyapatite (calcium / phosphorus = 1.5) into a three-necked flask containing 100 ml of distilled water, and inject ozone generated by a gas generator at a flow rate of about 450 ml / min, 55 oC The reaction was heated for 4 hours, the pH was adjusted to 3 with dilute hydrochloric acid, and steam distilled until the distillate was colorless. After concentration, cooling and filtration, 24.8 g of p-benzoquinone was isolated from the distillate (yield: 88.8%, product purity 98.0%).

[0020] Step b, synthetic hydroquinone

[0021] Take 20 grams of p-benzoquinone, 1 gram of Raney nickel and 40 milliliters of water into a pressure reaction bottle, fill it with 5 atmospheres of hydrogen (constant pressure), 50 oC Stir the reaction for 1 hour, cool down, filter out the catalyst Raney nickel for reuse, adjust the pH value to 2 with hydrochloric acid, cool down, precipitate the crude produc...

Embodiment 2

[0023] Step a, synthetic benzoquinone

[0024] Take 100 grams of sodium phenate and 10 grams of hydroxyapatite (calcium / phosphorus = 1.3) into a three-necked flask containing 300 ml of distilled water, and inject ozone generated by a gas generator at a flow rate of about 1000 ml / min, 55 oC The reaction was heated for 6 hours, the pH was adjusted to 3 with dilute hydrochloric acid, and steam distilled until the distillate was colorless. After concentration, cooling and filtration, 79.1 g of p-benzoquinone was isolated from the distillate (yield: 85.0%, product purity 97.2%).

[0025] Step b, synthetic hydroquinone

[0026] Get 200 grams of p-quinone, 20 grams of Raney nickel and 400 milliliters of water into a pressure reaction flask, fill with 10 atmospheres of hydrogen (constant pressure), 50 oC Stir the reaction for 2 hours, cool down, filter out the Raney nickel catalyst for reuse, adjust the pH value to 2 with hydrochloric acid, cool down, precipitate the crude product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com