A kind of preparation method of antibacterial functional cellulose fiber

A cellulose fiber and functional technology, applied in the field of antibacterial fiber preparation, can solve the problems of carcinogenic products, low immobilization efficiency, low utilization rate, etc., achieve high utilization, improve immobilization efficiency, and improve reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

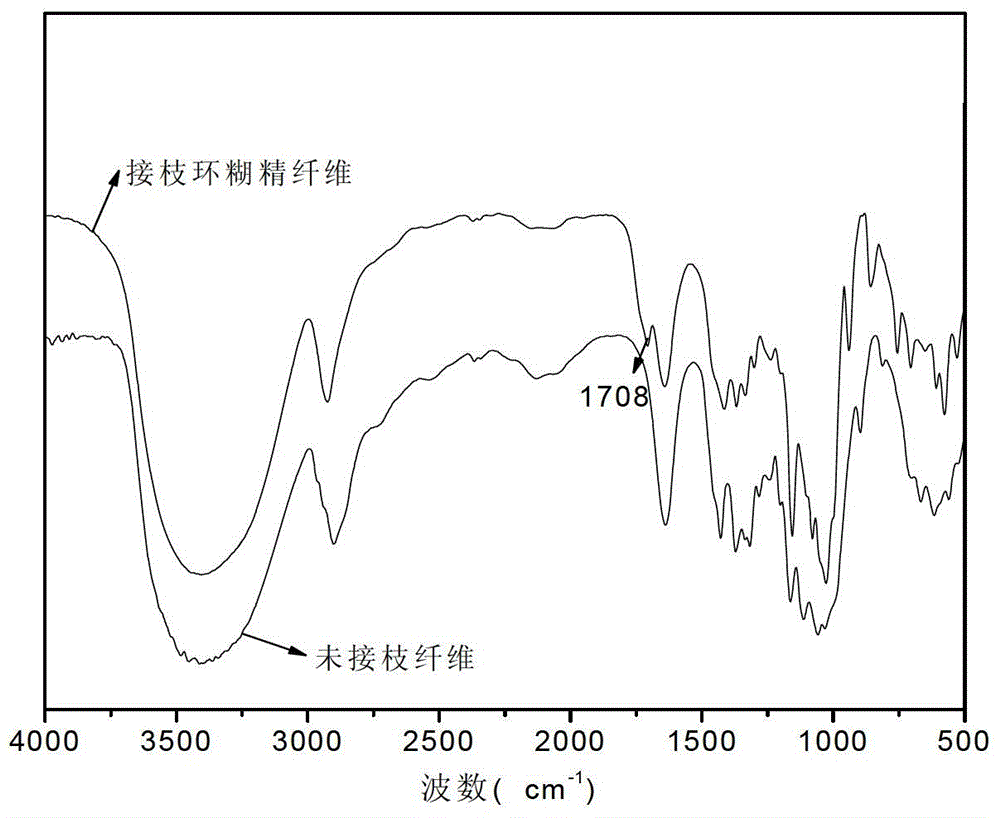

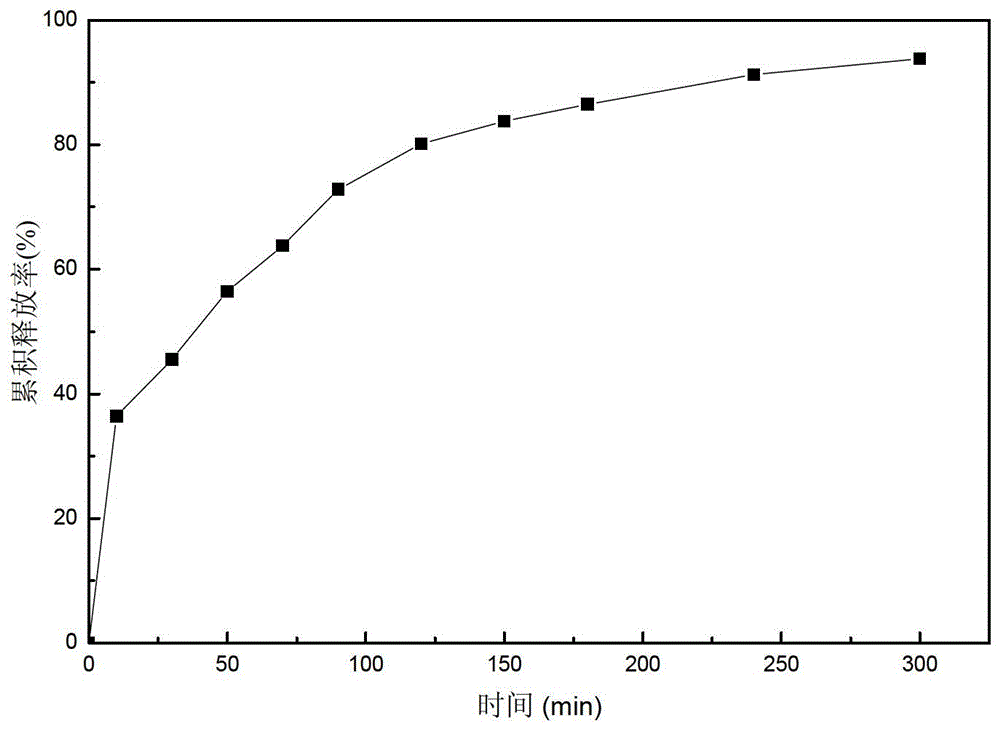

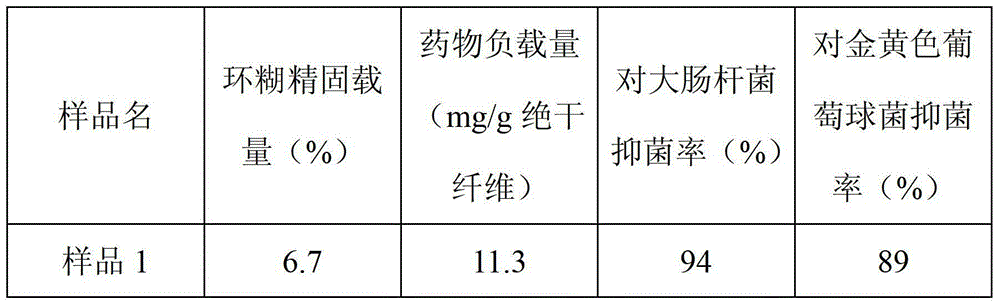

[0027] Put the cellulose fiber into 1.5mol / L sodium hydroxide solution to swell for 1 hour, the weight ratio of cellulose fiber to sodium hydroxide solution is 1:20; wash with distilled water until neutral, set aside; weigh 5g of β-cyclopaste Ethyl alcohol, 5 g of citric acid, and 0.5 g of sodium hypophosphite were respectively added to 50 ml of deionized water, stirred at 50°C for 15 min to completely dissolve, and a reaction solution was obtained. Soak 2g of swollen cellulose fiber into the reaction solution, after swelling for 15 minutes, put it in an ultrasonic cleaner for 55 minutes, and the frequency is 80KHz, and then put it into a blast drying oven at 150°C for curing reaction for 15 minutes. Afterwards, the fibers were washed three times with hot water at 50°C to obtain fibers grafted with β-cyclodextrin. Add 1g of the above fibers to 50ml of ciprofloxacin hydrochloride solution with a concentration of 2g / l, shake and adsorb in a constant temperature shaker at 200rpm ...

Embodiment 2

[0032] Put the cellulose fiber into 2mol / L sodium hydroxide solution to swell for 2 hours, the weight ratio of cellulose fiber to sodium hydroxide solution is 1:30; wash with distilled water until neutral, set aside; weigh 5g of β-cyclodextrin , 6g of citric acid and 0.75g of sodium dihydrogen phosphate were added to 50ml of deionized water, stirred at 60°C for 20min to dissolve completely, and a reaction solution was obtained. Soak 3g of swollen cellulose fiber into the reaction solution, after swelling for 20min, then put it into an ultrasonic cleaner for 30min, the frequency is 20KHz, and then put it into a blast drying oven at 160°C for curing reaction for 20min, Afterwards, wash the fiber with hot water at 60°C for 3 times to obtain the fiber grafted with β-cyclodextrin; put 2 g of the above fiber into 50 ml of ciprofloxacin hydrochloride solution with a concentration of 4 g / l, at room temperature at 200 rpm Vibrated and adsorbed in a constant temperature shaker for 6 hou...

Embodiment 3

[0036] Put the cellulose fiber into 3mol / L sodium hydroxide solution to swell for 3 hours, the weight ratio of cellulose fiber to sodium hydroxide solution is 1:40; wash with distilled water until neutral, set aside; weigh 5g of β-cyclodextrin , 5g of citric acid and 1g of disodium hydrogen phosphate were added to 50ml of deionized water, and stirred at 70°C for 30min to completely dissolve them to obtain a reaction solution. Soak 4g of swollen cellulose fiber into the reaction solution, after swelling for 30 minutes, put it into an ultrasonic cleaner for 50 minutes, and the frequency is 45KHz, and then put it into a 170°C blast drying oven for curing reaction for 30 minutes. Afterwards, wash the fiber with hot water at 70°C for 3 times to obtain the fiber grafted with β-cyclodextrin; put 1 g of the above fiber into 50 ml of triclosan solution with a concentration of 6 g / l, and set the temperature at room temperature at 200 rpm Shake and adsorb in a constant temperature shaker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com