Method for recovering liquid hydrocarbon and sodium hydrosulfide (NaHS) by purifying hydrogen desulfurization tail gas

A hydrodesulfurization and tail gas purification technology, which is applied in chemical instruments and methods, recovery of liquid hydrocarbon mixtures, sulfur compounds, etc., can solve the problems of environmental pollution caused by combustion and emission of hydrodesulfurization units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

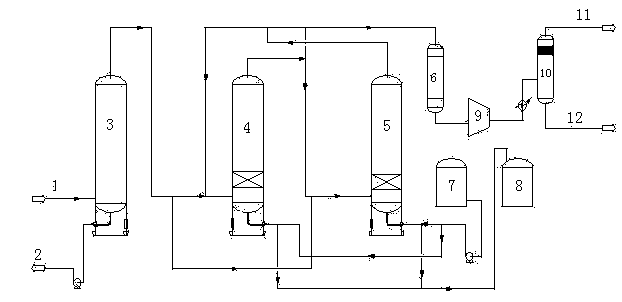

[0015] combine figure 1 The embodiment of this scheme is described, and the present invention is further explained.

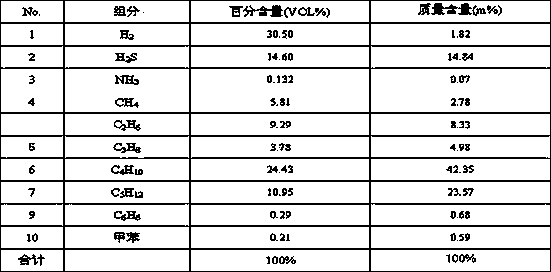

[0016] A crude benzene hydroprocessing enterprise in Hebei has a crude benzene hydrogenation tail gas flow rate: 300 Nm3 / h, temperature: 40 ° C, pressure: 0.4 Mpa, and the composition of the tail gas emission is shown in Table 1.

[0017] Table 1. Exhaust emission composition

[0018]

[0019] Such as figure 1 As shown in the schematic diagram of hydrodesulfurization tail gas purification and recovery of liquid hydrocarbons and NaHS, the tail gas 1 described in Table 1 enters the water washing tower 3 after passing through the tail gas buffer tank, and the small amount of ammonia and CO contained in the tail gas are washed. 2 , the solution 2 containing ammonia sulfide after washing is sent to the sour water stripping section for stripping treatment. After deamination, the gas passes through 4 and 5 two-stage lye absorption towers from bottom to top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com