Electrochemical preparation method of nitrogen-doped fluorescent carbon dots (NC-dots) with up-conversion and down-conversion functions

A technology of fluorescent carbon dots and conversion functions, applied in the field of carbon materials, can solve the problems of low fluorescence yield and high cost of products, and achieve the effects of high fluorescence yield, high universality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

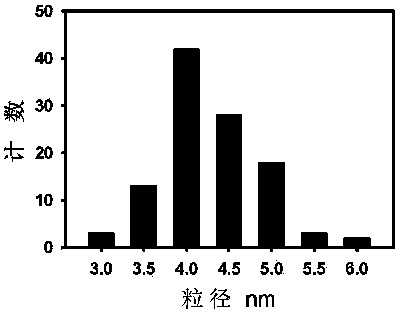

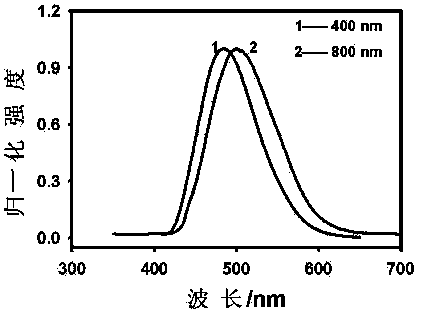

Embodiment 1

[0058] ① Control the potential with PS-305DM DC stabilized voltage power supply, and use platinum as the anode and cathode. In a 200ml beaker, add 20ml of water and 1.5g of sodium hydroxide to 140ml of ethanolamine, and use this as the electrolyte. NC-dots were prepared by electrochemical carbonization under constant potential mode for 4 hours by applying 15.0 volts.

[0059] ② After the reaction, the solution turns from colorless to brown-black, and it is allowed to stand still for several hours. Take the supernatant, and slowly add hydrochloric acid to it to neutralize the sodium hydroxide until it becomes neutral. Ethanol was then added to precipitate out the sodium salt. After resting, the supernatant was collected and the ethanol was removed by rotary evaporation.

[0060] ③ Concentrate the obtained solution, dialyze the C-dots solution with a dialysis bag with a cut-off of 1000, and obtain an aqueous solution of NC-dots after removing a small amount of salt.

[0061] T...

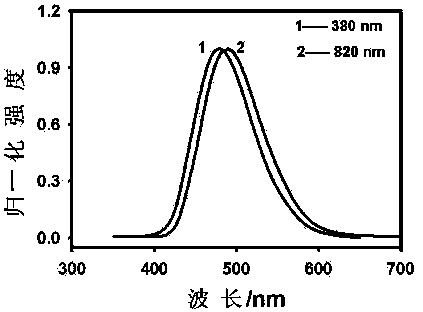

Embodiment 2

[0063] ①PS-305DM DC stabilized power supply control potential, platinum sheet as anode and cathode, in a 200ml beaker, add 20ml of water and 1.5g of sodium hydroxide to 150ml of ethanol / ethylenediamine (volume ratio 2; 1) to This serves as the electrolyte. NC-dots were prepared by electrochemical carbonization under constant potential mode for 4 hours by applying 15.0 volts.

[0064] ②After the reaction, the solution changed from colorless to brown-black, and stood still for several hours. Take the supernatant, and add hydrochloric acid to it to neutralize sodium hydroxide until it becomes neutral. Ethanol was added again, and a large amount of sodium salt was precipitated. Collect the reaction solution, remove ethanol by rotary evaporation (distilled ethanol can be used as carbonization raw material, or recycled to remove salt), and then ultrasonically disperse the obtained solid in pure water.

[0065] ③ The solution obtained by ultrasonic dispersion was dialyzed into the ...

Embodiment 3

[0068] ①PS-305DM DC stabilized power supply control potential, platinum sheet as anode and cathode, in a 200 ml beaker, add 20 ml of water and 1.5 g of sodium hydroxide to 150 ml of ethylene glycol / ethylenediamine (volume ratio 2; 1) , as the electrolyte. NC-dots were prepared by electrochemical carbonization under constant potential mode for 4 hours by applying 15.0 volts.

[0069] ②After the reaction, the solution changed from colorless to brown-black, and stood still for several hours. Take the supernatant, and add hydrochloric acid to it to neutralize sodium hydroxide until it becomes neutral. Ethanol was added again, and a large amount of sodium salt was precipitated. Collect the reaction solution, remove ethanol by rotary evaporation (distilled ethanol can be used as carbonization raw material, or recycled to remove salt), and then ultrasonically disperse the obtained solid in pure water.

[0070] ③ The solution obtained by ultrasonic dispersion was dialyzed into the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com