Butane dehydrogenation catalyst and preparation method thereof

A butane dehydrogenation and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of non-environmental protection, high price, activity and selectivity improvement, etc., and achieve improved mechanical strength And long-term operation stability, prevent damage and loss, improve the effect of activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

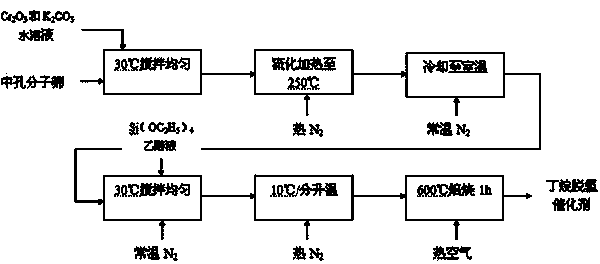

[0020] combined with figure 1 , further describe the present invention:

[0021] A butane dehydrogenation catalyst, consisting of the following materials by weight percentage:

[0022] Chromium trioxide: 12%~20%, potassium oxide: 1%~2%, vanadium pentoxide: 1%~2%, silicon dioxide: 1%~2%, molecular sieve: balance.

[0023] The preparation method of the present invention is:

[0024] (1) Preparation of Cr 2 o 3 and K 2 CO 3 After heating it to 30°C, slowly add it to the molecular sieve and stir evenly, heat the molecular sieve to 250°C under the action of N2 flow in the fluidized bed of the reactor, remove the impregnating liquid, and then cool to normal temperature;

[0025] (2) The molecular sieve in the fluidized state at room temperature in step (1) was uniformly dropped into Si(OC 2 h 5 ) 4 ethanol solution to fix the lattice of the active components in the molecular sieve;

[0026] (3) After adding the solution of step (2) and the molecular sieve is still in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com